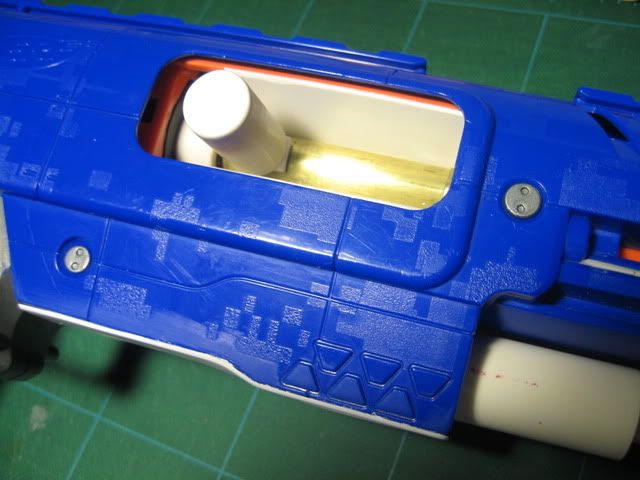

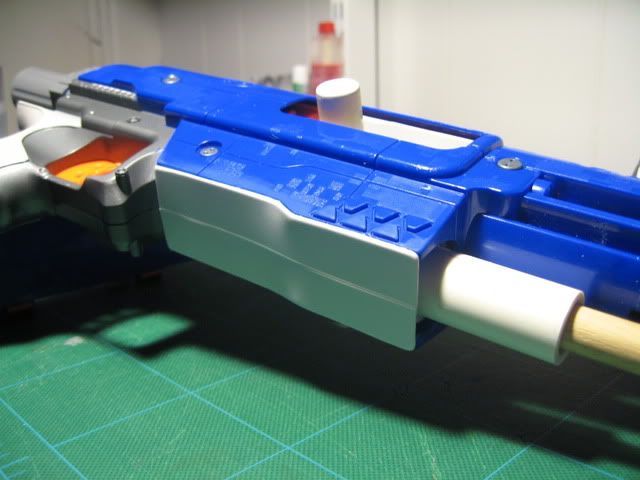

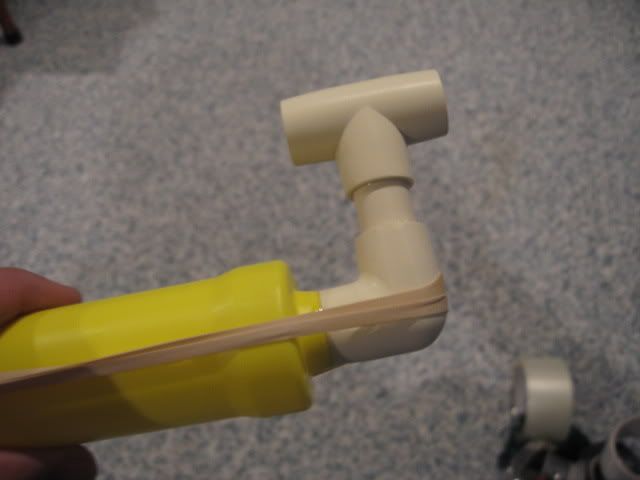

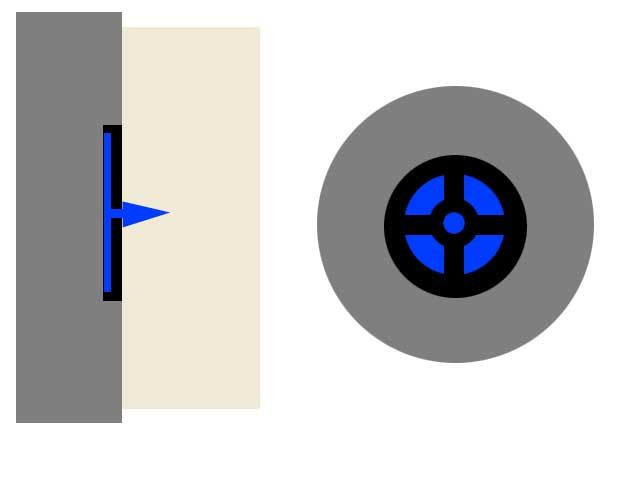

I carefully cut out the back of the pump wall and was able to determine how the check valve works. Here is the basic breakdown of the valve. This can be assembled again with styrene and glue.

The check valve which is made of rubber is blue.

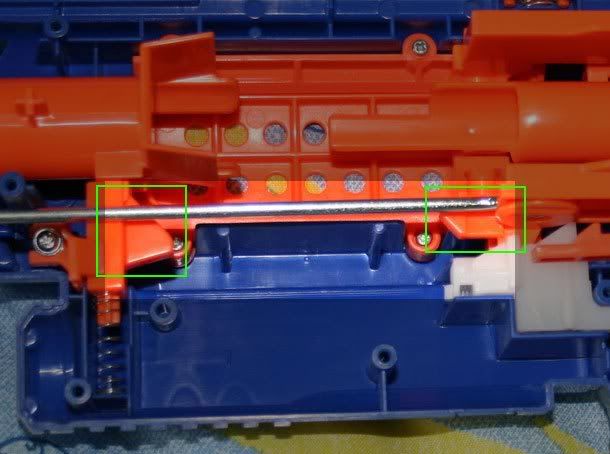

The valve stop is inside the pump tube and if that is dislodged (gets pushed into the back of the chamber), the check valve will fail. It was dislodged for me when I used a homemade pump. The stock pump head has a small hole in the middle of the head for the OPRV but also so the pump head does put too much pressure on the check stop to dislodge it.

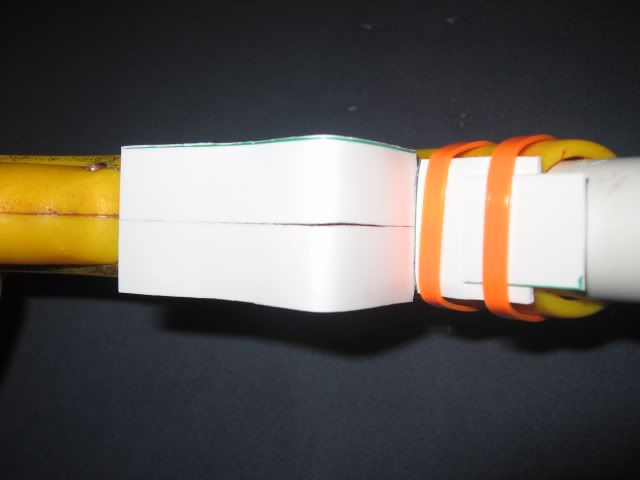

By using a plugged pump or a homemade pump where the pump head is flat, it can cause the valve stop to be pushed back and dislodge. In my next pump head, I simply coned out the head enough to avoid the check stop. When plugging pumps, be careful that it won't dislodge a check valve that might be in the pump tube.

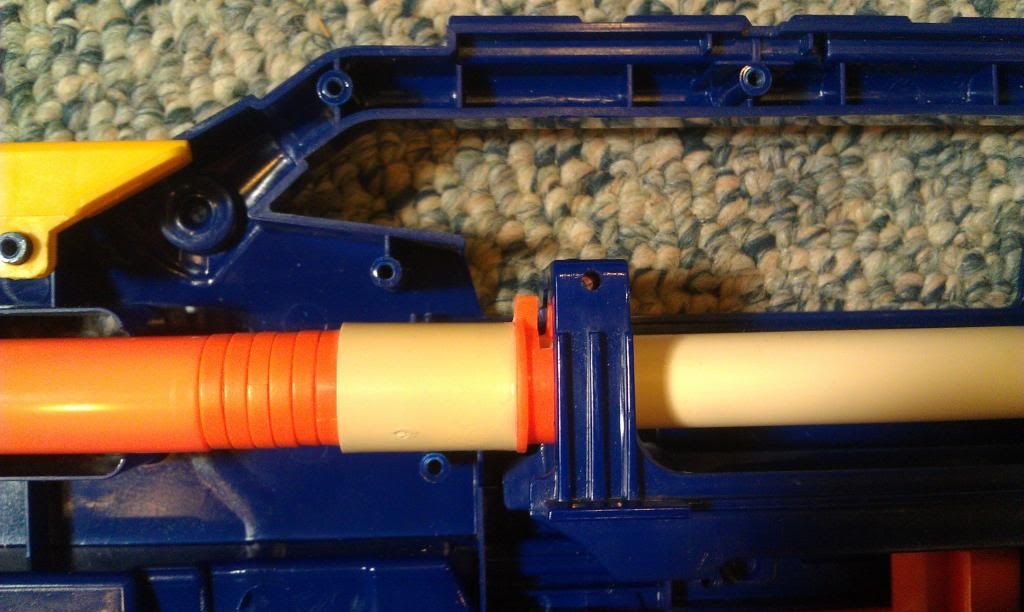

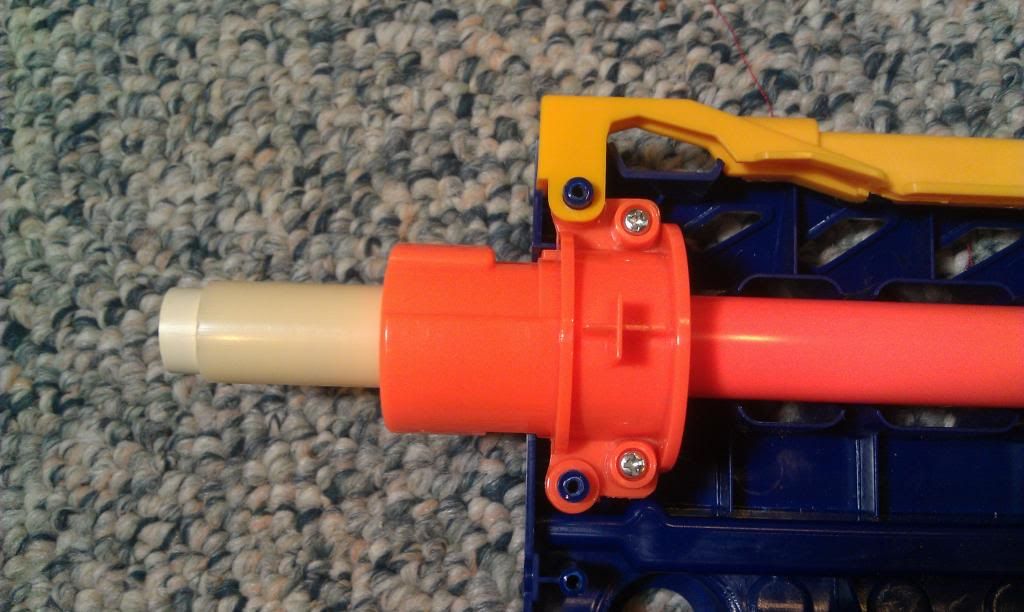

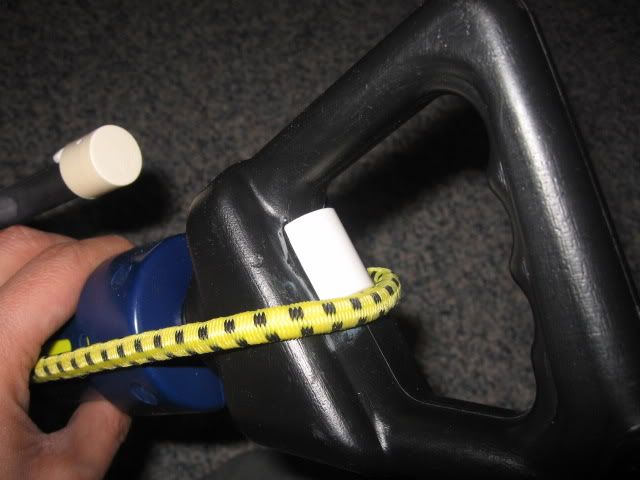

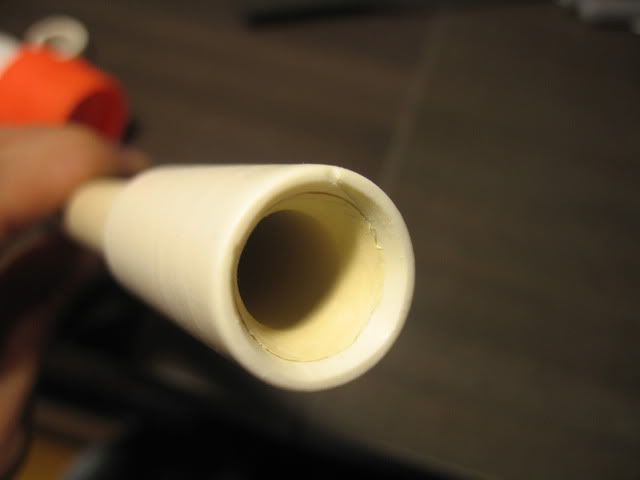

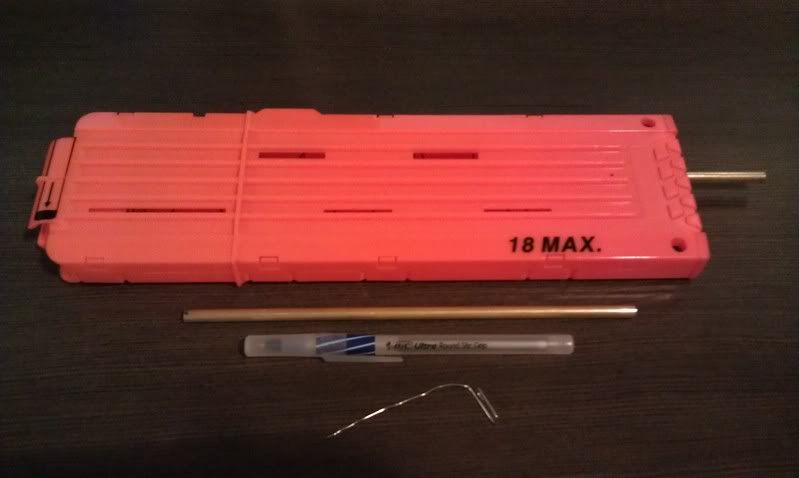

Add to this pump handle an o-ring that has a OD of 5/8 and you can nest PVC (wrapped in electrical tape) into the pump tube and keep the whole assembly intact.

Posted by

Posted by