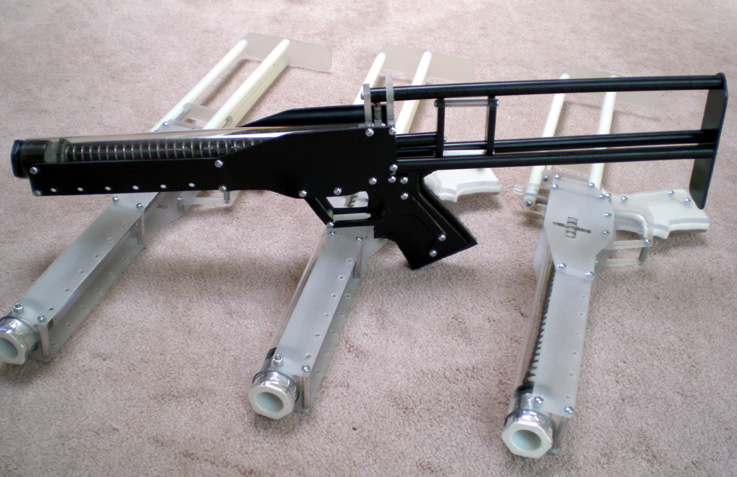

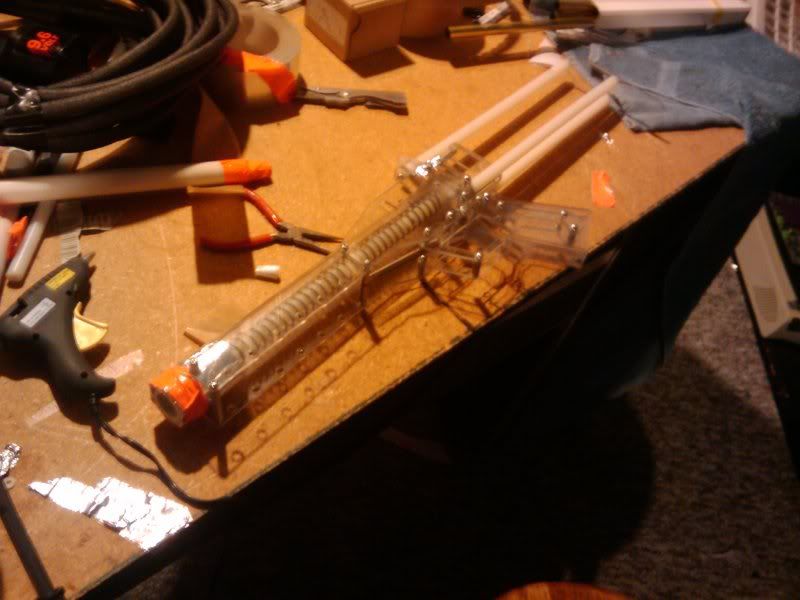

Alright! First the good news! Another +bow Rev. 2 has graced this world with its presence.

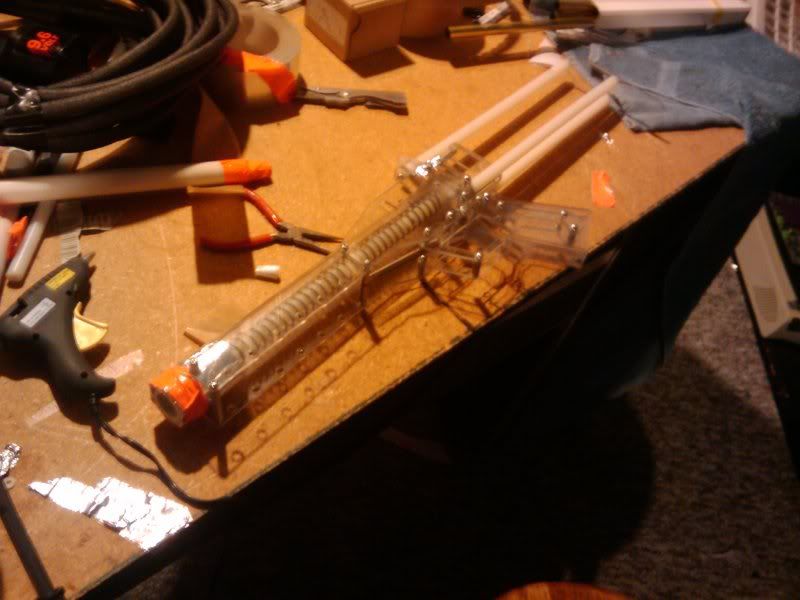

She's not the prettiest but she'll do.

Now on to the bad news. Despite my best efforts I have been unable to get this gun to fire past maybe half of what its range should be (50ft at best

).

I have followed CaptainSlug's instructions to the best of my ability and everything seems to be in working order. Now in hopes of getting rid of any simple mistakes I could have made, I will give you as much information as I can about My bow.

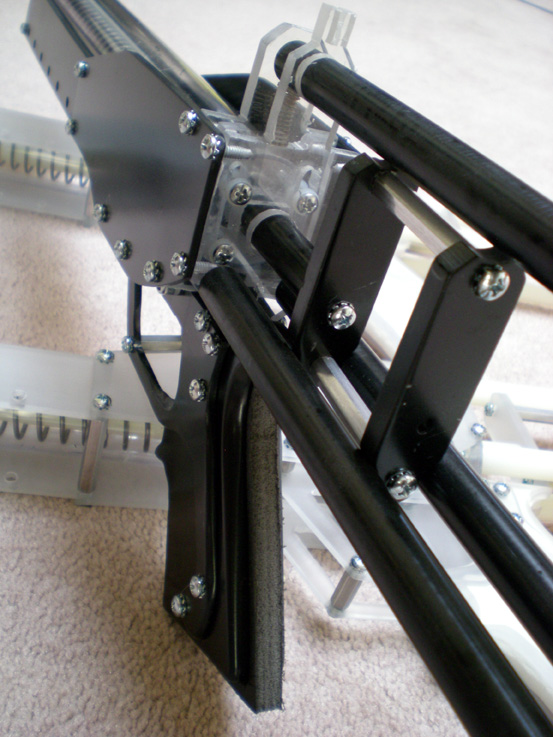

This picture, as you can tell, is the plunger head. It comes right up to the hex bushing adapter.

I have a clean seal using 2-3 layers of aluminum tape then a layer of Orange duct tape over that. I did NOT repeat

NOT over tighten the Bolt there.

The gun cocked.

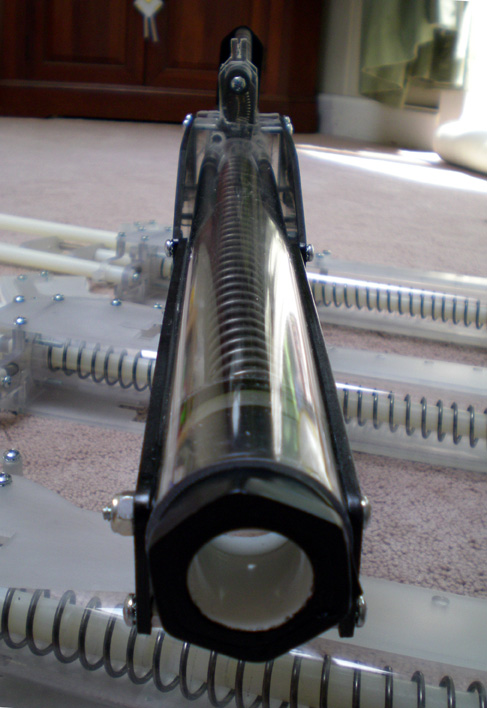

This is a temporary barrel I rigged up until I can make my breech barrel. It is 9/16 Brass in the front (where the stephan goes) nesseled inside of that is 17/32 Brass. Around those two is 19/32 Brass and that is all inside 1/2' PVC. To my knowledge this barrel should be more then adequate.

So that's 17/32 in 9/16 in 19/32 in 1/2' PVC.

The stephans I use are Captainslug's. Felt tip, #8 washer, and black FBR. They are roughly 2 inches Long. The lubricant I use is from Home Depot. It is Danco Inc. Silicone Grease. Is works fine in all my guns so I don't think the problem lies there.

Help guys, your my only hope. My Mav is getting better ranges!