You can only make the gun parts out of a material that you can add a #6-32 thread to. Polycarbonate is the cheapest, most durable, and easiest to machine material that I could possibly recommend. It can take far more abuse and mishandling than most other plastics.

Hardboard or any other kind of cheap fiber or wood byproduct material is not going to be able to hold a thread.

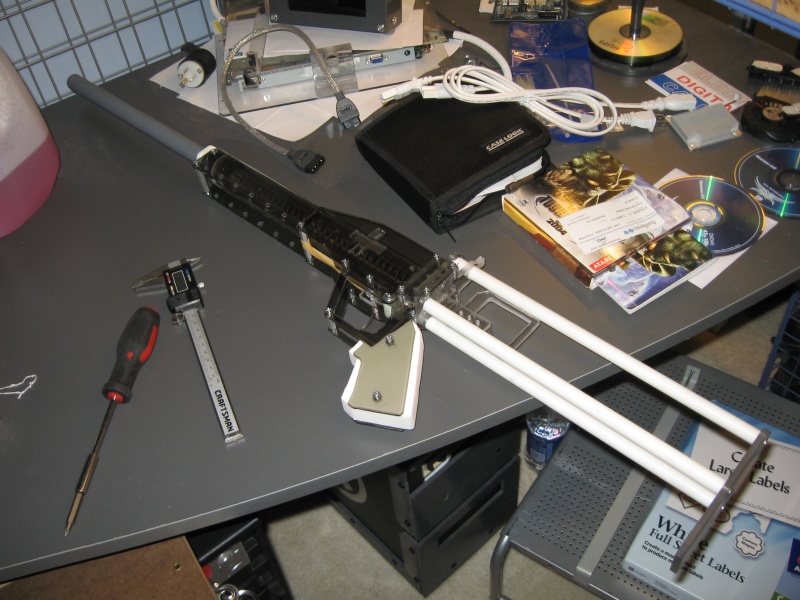

A band saw will let you do external cuts, but not internal ones. Half of the parts require a square hole be cut in the center of the parts for the plunger rod to pass through them. These cuts can only be done correctly using a scrollsaw since the cuts are inside of parts that are too small to safely work on with a jigsaw. I used a bandsaw to roughly trim the parts to size, but did all of the more intricate using a scrollsaw.

If you want to save money on materials you'll have to find a local supplier (plastics shop) that sells plastic off-cuts.

If you skimp on materials and tools you're not going to end up with the same gun. Sure it will be cheaper, but it won't be at all usable in a War. This gun has a GIGANTIC spring inside of it and alternative construction methods just won't be able to contain 25lbs of force.

Edited by CaptainSlug, 28 December 2007 - 01:56 AM.

This topic is locked

This topic is locked