#26

Posted 22 December 2007 - 01:39 PM

How well does this plastic take paint?

---

<death09>my girlfriend broke up with me and sent me pix of her and her new boyfriend in bed

<ktp753>ouch.

<death09>yeah.i sent them to her dad

#27

Posted 22 December 2007 - 02:13 PM

#28

Posted 22 December 2007 - 02:18 PM

I know the rail system works. I just don't have anything to put in the bracket right now.How is the rail/integrating part going?

Fine. Although I would recommend using vinyl dye to recolor polycarbonate. The resulting layer is extremely durable and won't rub off.How well does this plastic take paint?

#29

Posted 22 December 2007 - 02:38 PM

1. Go to the search button in the right corner of the screen

2. Click

3. Search double longshot clip.

#30

Posted 22 December 2007 - 02:43 PM

I also have to get close to 400 darts made between now and then.

Edited by CaptainSlug, 22 December 2007 - 02:43 PM.

#32

Posted 22 December 2007 - 04:58 PM

1. Go to the search button in the right corner of the screen

2. Click

3. Search double longshot clip.

#33

Posted 22 December 2007 - 06:49 PM

Edited by Matt31, 22 December 2007 - 06:50 PM.

"Who the hell died and made everyone the Nerf prophet?" -Piney

#34

Posted 22 December 2007 - 07:29 PM

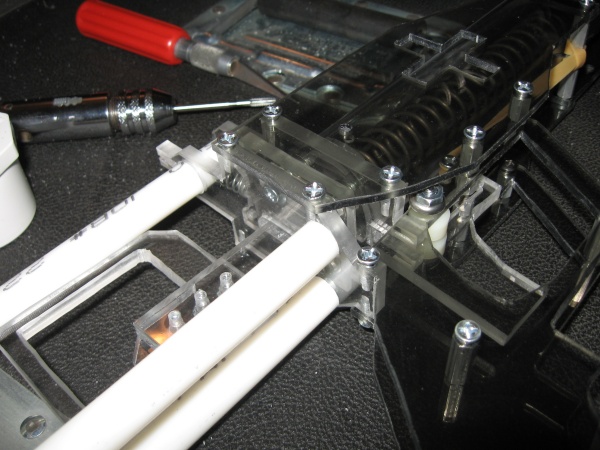

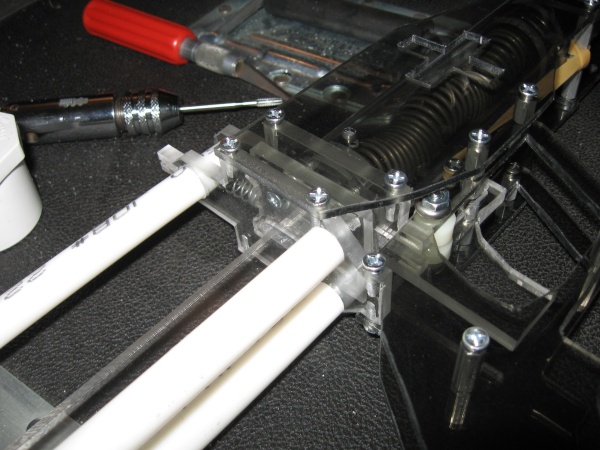

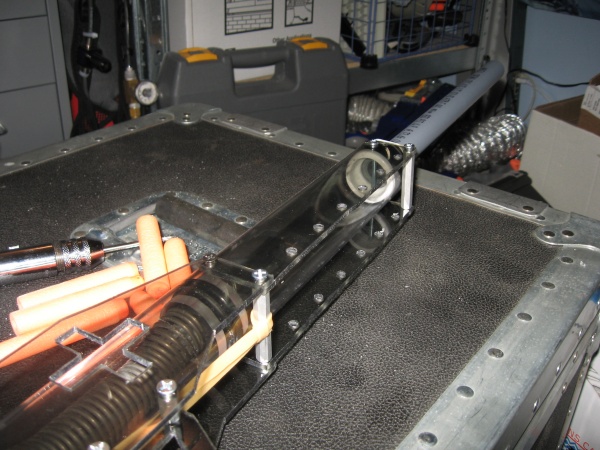

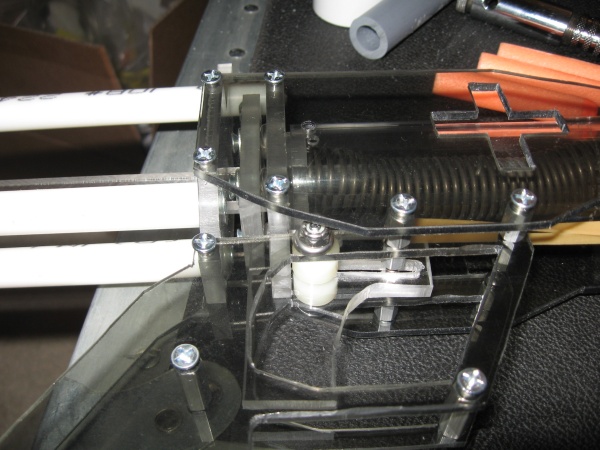

A rubber band was used on the trigger only because I have not yet received the shorter extension springs I ordered. The trigger works fine without a spring there, but I didn't want a wiggly trigger.

The plunger is held by a sliding catch plate, very similar to the one in the original crossbow. The trigger acts on the bevel edge to push and release the catch plate.

#35

Posted 22 December 2007 - 09:56 PM

plusbow_templates.doc (100KB)

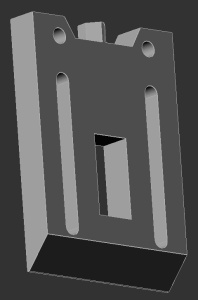

The only part not possible to print 1:1 templates for is the plunger rod, which is cut from 1/4" polycarbonate to 13.25" x 1/2". The labels for the ends of it are provided to show where to cut the notch and drill the holes.

The other parts are

1/2" OD Polyester Rod

---------------------

(2) cut to 11.25" length

(1) cut to 12" length

1" OD Polyester Rod

---------------------

(1) cut to 3/8" length

Mcmaster parts list

Raw Material --------------------------------------- 85805K43 - Gray Tinted Polycarbonate Sheet 1/4" Thick, 12" X 24" = $18.71 Each 85805K26 - Gray Tinted Polycarbonate Sheet 1/8" Thick, 12" X 12" = $5.16 Each 8541K18 - Black Nylon 6/6 Rod 1/2" Diameter = $1.02 per foot (5 feet) = $5.10 Each 8538K23 - Nylon 6/6 Rod 1" Diameter - $2.86 (for one foot) 8585K43 - Polycarbonate Round Tube 1-1/2" OD, 1-3/8" ID, Clear = $3.48 for one Foot 8865K122 - Tear-Resistant Polyethylene Foam Thick Sheet 3/4" Thick, 12" X 12", Plain Back, Gray = $6.91 Each (also available in White or Pink) Components ------------------- 4880K314 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1" X 1/2" Sz, Pipe End Male X Socket Fem, Hex Bushing = $0.74 Each 5308T347 - Hard Buna-N O-Ring AS568A Dash Number 316 - $3.68 per Pack of 50 9637K26 - Continuous-Length Compression Spring Spring-Tempered Steel, 11" L, .844" OD, .08" Wire - $10.12 per Pack of 5 9434K58 - Music Wire Precision Compression Spring Zinc-Plated, 11/16" Length, .30" OD, .032" Wire = $4.74 per Pack of 5 Hardware -------------------------- 90309A154 - Zinc-Plated Brass Unthreaded Round Spacer 3/8" OD, 1/4" Length, #6 Screw Size = $0.57 Each (2) 91780A125 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/8" Length, 6-32 Screw Size = $0.34 Each (4) 91780A131 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/4" Length, 6-32 Screw Size = $0.44 Each (3) 91780A337 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 1-1/2" Length, 6-32 Screw Size = $0.78 Each (2) 90272A146 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 3/8" Length = $1.66 per Pack of 100 90272A159 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 2" Length = $5.71 per Pack of 100 90272A157 - Zinc-Pltd Stl Pan Head Phillips Machine Screw 6-32 Thread, 1-1/2" Length = $3.51 per Pack of 100 90631A007 - Grade 2 Hex Nylon-Insert Locknut Zinc-Plated Steel, 6-32 Screw Sz, 5/16" W, 11/64" H = $1.85 per Pack of 100 90295A075 - Nylon 6/6 Flat Washer #6 Screw Size, .140" ID, .313" OD, .057"-.067" Thk = $2.68 per Pack of 100 List Total = $72.71 Enough material to make one complete +Bows with enough leftover hardware and components to cover the construction of atleast 2 or 3 more. No part substitutions recommended. No specific Barrel included in part list.

Tools to be required for making your own

+ Scrollsaw

+ PowerDrill or Drillpress

+ Mitre Box & Mitre Saw

+ #6-32 Tapping Bit

+ Screwdriver

+ Hobby Knife (to clean the edges of the sheets once cut)

No other tools expressly needed. All tools listed are not easily substitutable and I don't recommend attempting to make this gun with anything other than a scrollsaw due to the size of the parts you will be making.

Full plans including photographs of the whole process will be available sometime in the next two weeks.

Edit: fixed template sheet link

Edited by CaptainSlug, 05 January 2008 - 10:12 PM.

#36

Guest_CornMan_*

Guest_CornMan_*

Posted 22 December 2007 - 10:16 PM

#37

Posted 23 December 2007 - 12:28 AM

Edited by CaptainSlug, 23 December 2007 - 12:28 AM.

#38

Posted 23 December 2007 - 04:15 AM

#39

Posted 23 December 2007 - 11:15 AM

#40

Posted 23 December 2007 - 12:06 PM

Incredible job.

1. Go to the search button in the right corner of the screen

2. Click

3. Search double longshot clip.

#41

Posted 23 December 2007 - 01:58 PM

#42

Posted 23 December 2007 - 03:04 PM

< One foot in death...The other in life. >

#43

Posted 23 December 2007 - 04:51 PM

#44

Posted 23 December 2007 - 04:51 PM

sn1per I appreciate your humor, that made me laugh literally out loud.

"It's a free country, UNDER MY DICTATORSHIP!!!"

-Connor

#45

Posted 23 December 2007 - 05:25 PM

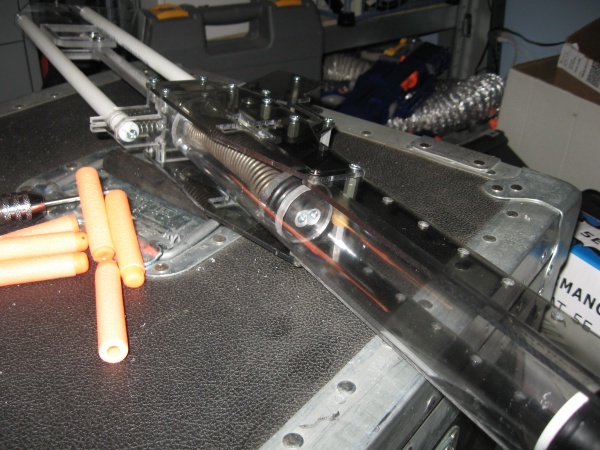

The plunger head is a sandwhich of 1/4" Polycarbonate, a 3/8" length piece of 1" Acetal rod (with two Dash 316 O-rings on it), and another piece of 1/4" polycarbonate. The rear piece of polycarbonate should be 1/8" though.Could you shed some light on what the plunger head is made out of?

With a 12-inch barrel it's 36 inches in length.How long is the gun altogether because it looks pretty long in the picture you have. Is it comparible to a LS or something the most people have?

The spring constant is 131.9 and the load applied to prime the plunger to the furthest forward notch is 25 pounds. I used a postal scale as a force gauge to read the load force needed to prime the plunger. If you need a less difficult to prime plunger then you simple cut the notch further back on the plunger rod.CS, it looks like you're using the full 11" spring. What's the spring rate or load, and how would you say it compares to the AR15 spring?

The spring used is almost identical to the AR-15 carbine spring.

Edited by CaptainSlug, 23 December 2007 - 05:35 PM.

#47

Posted 23 December 2007 - 08:47 PM

< One foot in death...The other in life. >

#48

Posted 23 December 2007 - 08:54 PM

Cutting the notch further back on the plunger rod will obviously decrease the range some. But will make it much easier to prime.

Edited by CaptainSlug, 23 December 2007 - 08:56 PM.

#49

Posted 23 December 2007 - 08:57 PM

As stated previously, Ranges are 110 to 140 feet. Dependent upon barrel length and darts used.

Sorry I missed that part. Wow nice ranges. How hard would this be for some one like me who has pretty much no experience in doing things like this?

< One foot in death...The other in life. >

#50

Posted 23 December 2007 - 09:09 PM

Edited by CaptainSlug, 23 December 2007 - 09:10 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked