#51

Posted 23 December 2007 - 09:58 PM

Great video.

1. Go to the search button in the right corner of the screen

2. Click

3. Search double longshot clip.

#52

Posted 24 December 2007 - 02:38 AM

#53

Posted 24 December 2007 - 04:48 AM

Replying through PM.Any chance I could get a hands-on demo? I'd love to drive/metro down there and check it out if you had a few free hours. And I'd be happy to write up my thoughts on the gun.

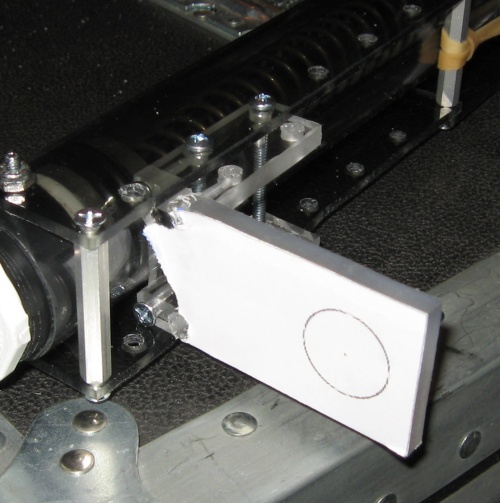

Here's some detail on the bracket system. The side panels on the gun are spaced to allow the adapter bracket to be used for integrations. You can affix the bracket using the same length of screws used to bolt the hex bushing adapter in place at the end of the plunger tube. Or the bracket can be held by quick-release pins. Either options allow you to integrate secondary weapons without having to glue or zip tie them directly to the body of the +Bow.

The front plate of the bracket is meant to have a hole drilled out at the same size as the barrel of the weapon you are trying to mount to the bracket. The most common sizes being a .84" diameter hole for 1/2" PVC pipe and a 9/16" diameter hole for the thin-walled PETG tubing.

You can then use zip ties through the holes in the side plates of the adapter bracket.

Front plates could be made for any weapon(s) you want to add. The first thing I would like to do is measure a splitfire so I can get holes spaced out on the adapter plate to match the spacing of the splitfire barrels. But the design is very open ended and can be adapted to whatever the end user wants.

I have no plans of my own for the adapter bracket at the moment. I just wanted the option to be there because so many people can take advantage of it. Please don't hesitate to post suggestions on what common integrations will need adapter brackets.

#54

Posted 24 December 2007 - 11:08 AM

AT2k/SM1500 valve, maybe some sort of box could be made to contain the valve and pump

Splitfire, as you mentioned, I think it would look nasty with a SF on there.

NF, I'm not sure if there is room for the cocking handle, but I think that this would look pretty sweet.

Titan valve/pump, It wouldn't be my cup of tea, but some would probably want this.

Thats all I can think of at the moment.

#55

Posted 24 December 2007 - 03:40 PM

Also how does the trigger hook into the catch plate?

#56

Posted 24 December 2007 - 05:06 PM

1. The '+' serves no functional purpose and is only there to reinforce the name of the weapon (+Bow). I would not appreciate having people mistakenly refer to this as a "Xbow" or "Crossbow" because it is not a modification of the original Nerf product but rather takes inspiration from it. Therefore it is the Plusbow, or +Bow for short.1. What purpose do those little cut out cross sections on the main body?

2. Also how does the trigger hook into the catch plate?

2. The catch plate is spring loaded to push down into the notch cut in the plunger rod. The trigger is pulled backwards and acts on the beveled edge of the catch plate to push it upwards and out of the notch in the plunger. Thus releasing the plunger and firing the dart.

Edit: Well that was easy, the foam core for the grip is done. It's very comfy.

Foam is also available in grey or pink.

Edited by CaptainSlug, 24 December 2007 - 05:35 PM.

#57

Posted 26 December 2007 - 04:39 PM

#58

Posted 26 December 2007 - 06:00 PM

Supplies to make the second +Bow will arrive in the mail tomorrow so I can start work on the write up.

#59

Posted 26 December 2007 - 08:34 PM

Anyways, that thing is a monster, I might just have nightmares about it coming out of my closet at night. Also, I must say, I feel bad for your 12 year-old neighbor, if I lived near you I'd be cautious when going outside for constant fear of being hit with a flurry of stefans raining down on me as I curl up into fetal position taking the foamy ownage. Seriously though, very nice work.

Edited by Blasphemy, 04 September 2008 - 05:51 PM.

#61

Posted 27 December 2007 - 10:36 AM

As for purchasing, I plan (or, as or now, planned) on selling most of my guns off and getting a crossbow and modding the bejesus out of it and make my solid primary. So I guess I'll get one of yours if you get them made in a good amount of time. Not rushing you on it. After all, I still need to sell my guns off. I just need to get an estimate on the gun.

So how much would you charge for one with pink foam? Not including shipping. Hopefully I could just pick one up at the next DCNO you and I attend.

Thanks

#62

Posted 27 December 2007 - 11:12 AM

Would it be possible to cut multiple (2 would be sufficient) catch notches in the plunger without reducing the structural integrity of the part. The only reason I ask this is because at 140ft I would not be willing to use the weapon in an actual nerf war (nor would I likely allow one at a war I was hosting) and it seems like a shame to to strip out the wow factor to make it useable in wars.

VACC

#63

Posted 27 December 2007 - 11:45 AM

Since I would have to buy a sheet of pink foam (no biggy since my sister will want the rest of the sheet) all I would tack onto the price is $5.So how much would you charge for one with pink foam? Not including shipping.

$90 + Shipping ($5) = $95

I'm not going to make any promises concerning when I will be able to make one available to anyone specifically. I can say I'm currently looking into the possibility of leasing-to-own a laser cutting table so that I don't have to commit myself to so much manual work to make the things people want to buy from me.

At the moment I still have a small backlog of people wanting longshot foregrips, and filling those orders will take priority in the next week or two.

I'm working on that right now. The plunger rod can have up to 3 notches in it to allow for several performance options. I just need to make sure having multiple notches doesn't lead to the plunger rod beating up the catchplate. If that is an issue then I can just offer different plunger rod options (have a 140foot max rod, a 110foot max rod, and an 80foot max rod).Would it be possible to cut multiple (2 would be sufficient) catch notches in the plunger without reducing the structural integrity of the part.

And now it's obvious why I used the whole spring rather than a section of it.

Edit: 3 Notches is working great so far. No problems to report.

I cut 2 extra notches spaced 1-inch apart and the lowest setting is giving roughly 80 feet as expected.

Edited by CaptainSlug, 27 December 2007 - 12:37 PM.

#64

Posted 27 December 2007 - 12:56 PM

The breech is mostly done. Pictures to come this afternoon

Since I would have to buy a sheet of pink foam (no biggy since my sister will want the rest of the sheet) all I would tack onto the price is $5.So how much would you charge for one with pink foam? Not including shipping.

$90 + Shipping ($5) = $95

I'm not going to make any promises concerning when I will be able to make one available to anyone specifically. I can say I'm currently looking into the possibility of leasing-to-own a laser cutting table so that I don't have to commit myself to so much manual work to make the things people want to buy from me.

At the moment I still have a small backlog of people wanting longshot foregrips, and filling those orders will take priority in the next week or two.I'm working on that right now. The plunger rod can have up to 3 notches in it to allow for several performance options. I just need to make sure having multiple notches doesn't lead to the plunger rod beating up the catchplate. If that is an issue then I can just offer different plunger rod options (have a 140foot max rod, a 110foot max rod, and an 80foot max rod).Would it be possible to cut multiple (2 would be sufficient) catch notches in the plunger without reducing the structural integrity of the part.

And now it's obvious why I used the whole spring rather than a section of it.

Edit: 3 Notches is working great so far. No problems to report.

I cut 2 extra notches spaced 1-inch apart and the lowest setting is giving roughly 80 feet as expected.

That is fantastic. Most modders are not willing to decrease the range of their "masterpieces" to increase their utility. Now, how many hugs do you think one of these will set me back? I'm willing to throw in some fondling if it will seal the deal.

VACC

~master negotiator~

#65

Posted 27 December 2007 - 01:22 PM

#66

Posted 27 December 2007 - 05:40 PM

I wonder what nerf would be like without Captain Slug... It would be a lot different though.

I'm obviously down for one of these.

The range reduction idea is great. So how long will it take to switch from 140' to 80'? You have to open up the gun right?

Just awesome.

#67

Posted 27 December 2007 - 06:32 PM

-Nerfer34

You know what... I know it's kinda late... but Props Cole.

-Baghead

#68

Posted 27 December 2007 - 07:40 PM

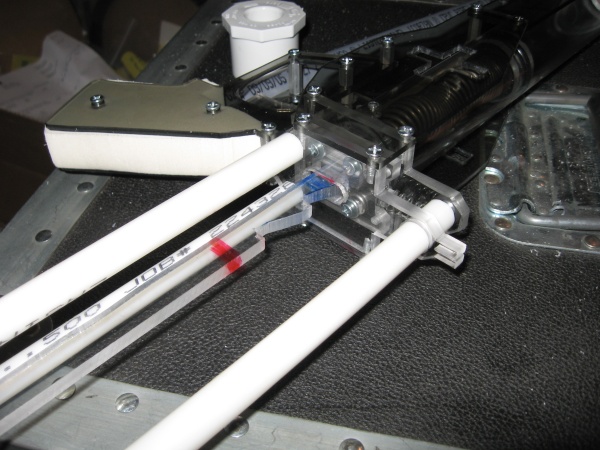

The breech I'm working on. Not yet sure if the handle is durable enough. I'll find out tomorrow.

Edited by CaptainSlug, 27 December 2007 - 07:41 PM.

#69

Posted 27 December 2007 - 07:48 PM

One man Clan:

I saw the Crossbow re-release on the shelf at my local Target, but I didn't want to tell anyone because I wanted them all to myself. I hid them all behind Dora the Explorer toys....

[/quote]

#70

Posted 27 December 2007 - 10:07 PM

Hmm... I want to be the first one to own one of these so I will pay $110.

EARN EASY MONEY... 100's a month.

#71

Posted 27 December 2007 - 10:26 PM

And just to be clear this is something I made for my +Bow. I have no intention of including barrels with the version I will eventually make and sell. I cannot predict what barrel works best with your darts, so that part of the gun will be left up to you. A basic 12" CPVC barrel could be included upon request.

#72

Posted 27 December 2007 - 11:39 PM

---

<death09>my girlfriend broke up with me and sent me pix of her and her new boyfriend in bed

<ktp753>ouch.

<death09>yeah.i sent them to her dad

#73

Posted 27 December 2007 - 11:43 PM

#74

Posted 28 December 2007 - 12:03 AM

The end of the plunger tube is a normal 1/2" Pipe Bushing so any length of 1/2" pipe can be used with your preferred barrel material nested inside of it.

That will be taken into consideration. Thanks for sharing as I now have more ideas then I did before with barrel mods.

EARN EASY MONEY... 100's a month.

#75

Posted 28 December 2007 - 01:32 AM

I know you don't recommend it, but do you think that this could be done with a small band saw? It's got a fairly tight turning radius, especially if I make lots of relief cuts. And is there a possibility that there are ways to reduce material cost more? I looked over the parts list a couple times, and the main cost is in raw material - getting that down to something a little more reasonable (around 20) would make me want to try my hand at building one. For instance, do you know the characteristics of hardboard (Kinda like pegboard material, for those who don't know, and sold by the 4x8 sheet in the required thicknesses for less than the required sizes of Lexan), and is it sufficient for most of the parts on this beast? I could probably figure out a different material for the charging handle if I had to, and a different tube for the plunger itself; I'm avoiding McMaster altogether until I can convince myself I can do this.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked