#101

Posted 05 January 2008 - 10:27 PM

Awesome write up.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#102

Posted 05 January 2008 - 10:31 PM

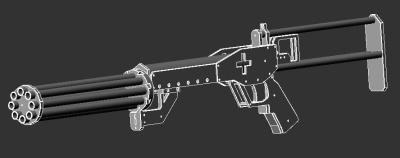

For now I have the breech which works really well.

Eventually I would like to make a 6-barrel turret. But the options are limitless because I purposefully didn't design any specific barrel into the gun itself.

#103

Posted 05 January 2008 - 11:53 PM

#104

Posted 06 January 2008 - 12:19 AM

#105

Posted 06 January 2008 - 12:36 AM

I know that people say that Mcmaster no longer ships to Canada but when i went looking through there help files I noticed it said that they will ground ship to most Canada. Was this section just not updated? Another quick question sorry does anyone know for sure whether or not Mcmaster will ship to American P.O. boxes?Very nice write-up. I'm sure I'll eventually attempt this, but McMaster doesn't ship to Canada anymore, so it'll be quite a long time before I find all the parts necessary to make one of my own.

#106

Posted 06 January 2008 - 01:50 AM

#107

Posted 06 January 2008 - 01:53 AM

The plunger rod is made from 1/4" thickness polycarbonate and has to be 13-1/2" inches long in order for there to be enough material to allow you to bolt the priming handle onto it. If it were 12 inches long it wouldn't make it out the back of the rear frame piece.

The plunger rod is one part I would be willing to make for people if they are having difficulty. It's a very easy part to make using a table saw and a band saw, but not as easy to make cleanly with just a scroll saw.

OR you could order a 2-foot length of rectangular rod that has the right dimensions you want, then just cut it to length. The only thing usable that you can order is

8702K61 - Polyethylene (UHMW) Rectangular Bar 1/4" Thick, 1/2" Wide = $1.28 for 2 feet

Then order a smaller sheet of polycarbonate. UHMW Polyethylene is pretty durable stuff, but I'm not completely sure how well it will stack up against polycarbonate when it comes to progressive amounts of abuse over time. using it would be an interesting experiment and would shave $12 off the part list total.

Edited by CaptainSlug, 06 January 2008 - 02:02 AM.

#108

Posted 06 January 2008 - 12:03 PM

Black Nylon 6/6 Rod 1/2" (5 feet)

8538K23 - Nylon 6/6 Rod 1" Diameter

Polycarbonate Round Tube 1-1/2" OD, 1-3/8" ID, Clear

Zinc-Plated Brass Unthreaded Round Spacer 3/8" OD, 1/4" Length, #6 Screw Size

Aluminum Male-Female Threaded Hex Standoff 1/4" Hex, 1/4" Length, 6-32 Screw Size

Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/8" Length, 6-32 Screw Size

Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/4" Length, 6-32 Screw Size

Aluminum Female Threaded Hex Standoff 1/4" Hex, 1-1/2" Length, 6-32 Screw Size

Also, Is your breech merely a PETG tubing with the knob on it put inside the PVC? So when you slide it forward you can put the dart into the rear of the PETG? Which means I can substitute the PETG with Brass (and an appropriate PVC size)

Next, Where did you find full sheet labels? I looked at all of my office stores but to no avail, later this week I will check kinkos though.

Thanks.

Edited by Peter, 06 January 2008 - 12:06 PM.

#109

Posted 06 January 2008 - 01:12 PM

I should be able to make one of these before Friday. Assuming I can make enough darts first.

1. All of the plastics chosen to make this gun are very easy to tap. You can even tap polycarbonate using a poly drill with little effort. Just make sure to keep the tapping bit from getting too hot, and clean the shavings off of it after each hole you tap.1. How difficult is the tapping and threading?

2. So I would need the following materials in multiples of the amount of guns to be made?

3. Also, Is your breech merely a PETG tubing with the knob on it put inside the PVC? So when you slide it forward you can put the dart into the rear of the PETG? Which means I can substitute the PETG with Brass (and an appropriate PVC size)

4. Next, Where did you find full sheet labels?

2. Here's a list of materials you will need to order more of and why.

Provides some excess, but not enough to make more guns. 8541K18 - Black Nylon 6/6 Rod 1/2" Diameter = $1.02 per foot (5 feet) = $5.10 Each For the items below multiply amount by the number of +bows you are trying to make. 8585K43 - Polycarbonate Round Tube 1-1/2" OD, 1-3/8" ID, Clear = $3.48 for one Foot 4880K314 - Std-Wall (Schedule 40) White PVC Pipe Fitting 1" X 1/2" Sz, Pipe End Male X Socket Fem, Hex Bushing = $0.74 Each 90309A154 - Zinc-Plated Brass Unthreaded Round Spacer 3/8" OD, 1/4" Length, #6 Screw Size = $0.57 Each (2) 93505A440 - Aluminum Male-Female Threaded Hex Standoff 1/4" Hex, 1/4" Length, 6-32 Screw Size = $0.49 Each (2) 91780A125 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/8" Length, 6-32 Screw Size = $0.34 Each (4) 91780A131 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 3/4" Length, 6-32 Screw Size = $0.44 Each (3) 91780A337 - Aluminum Female Threaded Hex Standoff 1/4" Hex, 1-1/2" Length, 6-32 Screw Size = $0.78 Each (2)You do not need more of the 1" diameter rod because it is only cut to 3/8" lengths to make the core of the plunger rod. The pack of 100 3/8" length screws will give you just enough to make three guns (the gun uses around 33 of that length of screw).

3. I had to bore out the inside diameter of the PVC pipe using a machine lathe to get the PETG to slide and seal inside of it. I then milled the notch using a manual knee mill.

I solvent-welded a tab onto the PETG to make sure the barrel doesn't slide forward when the gun is fired.

I don't recommend trying to make this kind of breech if you do not have access to a lathe and some practice using it.

4. Office Depot, Staples, and sometime Target carry them near the other kinds of label paper. like the return address or mailing label ones that are pre-cut to size. They're kind of pricey at around $35 for 100 sheets.

Edited by CaptainSlug, 06 January 2008 - 02:13 PM.

#110

Posted 06 January 2008 - 03:32 PM

8 shots at 120'. And you can probably get those 8 shots off in 10-12 seconds....

That's just great work.

#111

Posted 06 January 2008 - 04:22 PM

-Nerfer34

You know what... I know it's kinda late... but Props Cole.

-Baghead

#112

Posted 06 January 2008 - 08:40 PM

No, probably not that fast. It will probably be more like 45 seconds8 shots at 120'. And you can probably get those 8 shots off in 10-12 seconds....

1. I know of one way to add one, but I don't think it would make it any easier to prime such a powerful spring unless my arm were as big as FA24s.1. Now it needs a shotgun pump.

2. I think I can get these parts made at the rapid prototyper at the college here. Depending on the cost, I may be able to sell some parts. I also am not sure about the durability. If anyone has a Desktop Factory, you may want to contact them.

2. That's a generous offer, but current 3D printers print parts in either urethane with a binder, ABS, or a light cured polyester or other resin medium. None of those materials are strong enough to make most of the parts for this gun. They're great for demonstrational models, but for actual working parts all but the ABS 3D printers are not useful.

And to make the parts out of ABS I would have to design them with that material in mind.

Edited by CaptainSlug, 06 January 2008 - 08:44 PM.

#113

Posted 06 January 2008 - 09:33 PM

VACC

~Did I mention that I need one of these.......to cure cancer?~

#114

Posted 06 January 2008 - 09:43 PM

Edited by CaptainSlug, 06 January 2008 - 09:44 PM.

#115

Posted 06 January 2008 - 09:52 PM

Thats what I was thinking. Their stuff looks to be pretty durable. And its made out of high density plastic, and you can insert an even higher density pellet to make the parts stronger.

-Nerfer34

You know what... I know it's kinda late... but Props Cole.

-Baghead

#116

Posted 06 January 2008 - 09:56 PM

I research manufacturing options for both work and fun. I'm weird like that. Water-jet and laser cutting services are really the only feasible ways of making these parts in bulk. But the cost for services with those tools are much higher than I want to pay.

I don't need anymore manufacturing suggestions.

Unless you

1. have a relative that is willing to give me a significantly reduced rate on that type of service

2. have a laser or water-jet cutting table at your disposal and are willing to bend to my whims for a share in the profits making these guns

3. for some strange reason have $13,000 dollars you don't have anything to do with and would like to just give it to me so I can buy a laser cutting table

then I probably don't near to hear about it at this time. Thank you.

Edited by CaptainSlug, 06 January 2008 - 10:03 PM.

#117

Posted 07 January 2008 - 12:48 AM

Can't you find an already used laser cutter?

#118

Posted 07 January 2008 - 04:03 AM

Used ones that do go up for sale are the gigantic 9x6 foot models from the 80s and will sell for the same price as newer smaller ones.Can't you find an already used laser cutter?

It's not an item with a high turnaround rate.

#119

Posted 07 January 2008 - 03:38 PM

#120

Posted 07 January 2008 - 03:41 PM

Initial supply cost if you're buying all the materials is around $80. But if you make one it involves $20-$30 of parts and supplies and you end up with $45 worth of excess. There's no way to buy exactly how much you need.Sorry if this has been asked before, but about how much do they cost to make from scratch?

I have lots of scrap plastic, so I can't calculate precisely how much each one costs me to make. It's probably around $20.

Edited by CaptainSlug, 07 January 2008 - 03:53 PM.

#121

Posted 07 January 2008 - 04:09 PM

A. These guns and ideas will and do and can rock the house.

B. None of us can make them without paying a freakin lot for tools, materials, and parts.

C. The only person on the Haven who can and will make them is Sluggy.

D. He is the only person to buy them from.

E. Sluggy can make a small fortune off of this?

(F.) I got my foregrip today, it's sweet, TY.

-Piney-

"It is amazing what a bit of conversation can do, as apposed to just *^$(*#*^ about it."

-AJAQ-

#122

Posted 07 January 2008 - 04:25 PM

A. Pretty muchSo let me get a few things straight:

A. These guns and ideas will and do and can rock the house.

B. None of us can make them without paying a freakin lot for tools, materials, and parts.

C. The only person on the Haven who can and will make them is Sluggy.

D. He is the only person to buy them from.

E. Sluggy can make a small fortune off of this?

B. The only expensive tool I own is a contractor grade table saw, which I didn't really make heavy of to make this gun. At bare minimum you will need a power drill ($30), a scroll saw ($100), and a tapping bit ($6).

C. There are at least 10 other members I am aware of that have the tools needed to make these on their own. There are probably others I am not aware of.

D. Debatable. If you have a friend who has the right tools and a weekend in which they would be willing to help you, I'm all for you buying them dinner or bribing them in some other manner to help you make your own.

E. If by fortune you mean I would be compensated for the 10 hours (one whole waking day of effort) it would take to make one, then maybe so. If I had a more efficient way of making these I could reduce the price significantly. As it stands now, if I do make more of these with the intent to sell them the starting price will be $120 each. That's $20 for supplies and $10/hour for labor.

And speaking of the foregrip kits, my time is compensated when I make those as well. I wouldn't make and sell them if I had to do so at a loss.

Edited by CaptainSlug, 07 January 2008 - 04:29 PM.

#123

Posted 07 January 2008 - 04:36 PM

-Piney-

"It is amazing what a bit of conversation can do, as apposed to just *^$(*#*^ about it."

-AJAQ-

#124

Posted 07 January 2008 - 09:07 PM

-Nerfer34

You know what... I know it's kinda late... but Props Cole.

-Baghead

#125

Posted 08 January 2008 - 12:12 AM

But of course, yours can't be as good as Slug's. And what would be $80?Me and Trojan Nerf will be making them when we finish our first batch for ourselves. We will have 3 guys working in assembly line fashion at a machine shop, so, as soon as supplies are bought, we will be fine, I can estimate 80 dollars if I did the math right.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked