#301

Posted 20 September 2007 - 08:08 PM

But, alas, your right. I'm going to work with a carrier now. The ramp is just too inefficient and unreliable for me to actually use in a war, against trained marksman. If the shells were to jam up, or a shell wouldn't be chambered correctly, I'd have to spend valuable time taking apart the weapon to un-jam it.

I believe I'll try Meaker's idea next, and I believe I know a way to make a pin in front of the magtube, that is depressed when the carrier is lowered.

#302

Posted 20 September 2007 - 08:29 PM

Also, when you get to Ronster's idea (assuming that the others fail), you may need to do something extra on the design. The carrier track would have to be as long as your plunger travel length, and that will get annoying if it is more than 2" (mine is 4"). If you have the pin that engages it come in later and be separate when the weapon is ready to fire (have it not be in the track when the bolt and pump are in their foremost positions), you have to make absolute certain that the pin will engage the slot every time, or you may wreck the carrier.

I think that someone posted a picture of the tab on the bottom of a shotgun carrier that keeps shells in place a while ago. You may have to follow a link to find it, though...

Edited by SHADOW HUNTER ALPHA, 20 September 2007 - 08:30 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#303

Posted 22 September 2007 - 09:40 PM

Also, when you get to Ronster's idea (assuming that the others fail), you may need to do something extra on the design. The carrier track would have to be as long as your plunger travel length, and that will get annoying if it is more than 2" (mine is 4").

This is where my idea comes in, finally. I've been waiting forever to say this.

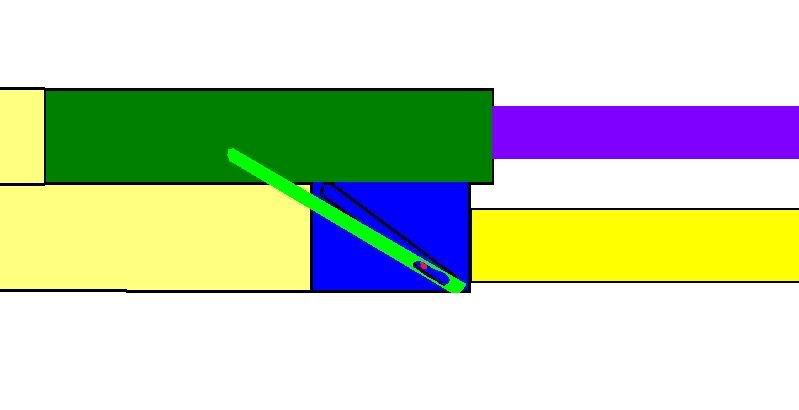

Lime green - Rod attaching carrier to bolt

Hot pink - Rod that is underneath carrier, which is pulled up by rod

Blue - Ronster's carrier idea

Yellow - Magtube

Green - Main receiver

Let's hope you understand that. Basically, the lime green is the rod that attaches the bolt to the carrier, as shown in Ronster's carrier idea. But, a slit could be cut into that rod, so that it wouldn't come into contact with the carrier and move it upwards after the plunger has already been pushed back a short distance, shortening the length of the carrier path. And when the plunger has caught on the catch, and the bolt is being pushed forward, the carrier wouldn't lower until it comes in contact with the other side of the slit, letting the bolt chamber the shell before the carrier lowers.

I think I just solved two of my own problems at once.

#304

Posted 22 September 2007 - 09:44 PM

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#305

Posted 22 September 2007 - 09:48 PM

When Ronster posted his carrier idea, the carrier frame was square.

How the hell is a square frame going to fit into rounded PVC? (No offense Ronster)

I'm gonna have to come up with a way to make a rounded version of Ronster's carrier. Just not sure how yet. I'll probably have it done within a few days though.

#306

Posted 22 September 2007 - 09:55 PM

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#307

Posted 23 September 2007 - 12:42 PM

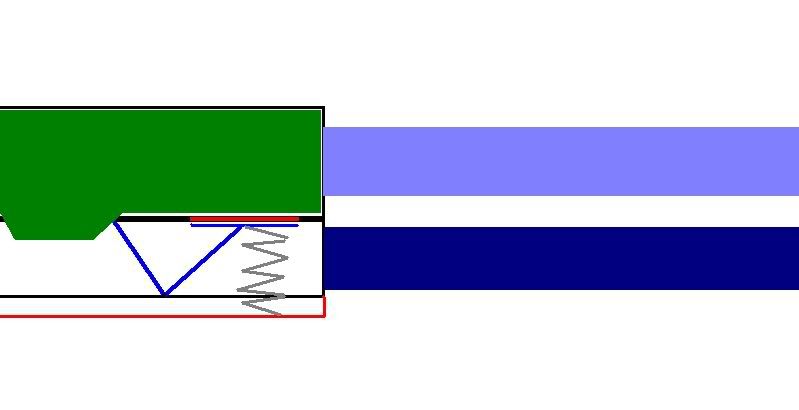

In a real shotgun, the carrier is lowered when inactive and raised as the bolt moves backwards. But this isn't a real shotgun, is it?

What you see is a V-shape carrier design. Basically, the picture shows when the pump is pushed back. The bolt rail, which is shone by the trapezoid shape on the bottom of the bolt, is not in contact with the carrier V. Think of the V as one solid piece. except for a hinge located in between the carrier and the carrier v, so it can pivot and stay level. When the bolt is pushed forward again, the bolt connects with the shell before the trapezoid rail connects with the carrier V, allowing the shell, once again, to be chambered before the carrier lowers. When the trapezoid does connect, it pushes the carrier down, against the spring. The carrier V never gets on the other side of the trapezoid fin though, eliminating the problem of it suddenly rising. When the bolt is moved back, however, and the trapezoid fin releases the V, the spring pushes the carrier upwards again, so the cycle can be repeated.

Also, the carrier could be used as the loading port cover, possibly, so the pump would have to be back for another shell to be loaded.

#308

Posted 23 September 2007 - 12:54 PM

Edited by SHADOW HUNTER ALPHA, 23 September 2007 - 12:54 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#309

Posted 23 September 2007 - 02:02 PM

#310

Posted 02 October 2007 - 05:06 PM

Some lever-action firearms have a tube magazine and utilize a lifter/carrier; pump-action shot guns aren't the only ones. Now, I've personally handled and worked the action of a Winchester 94AE, and it has some interesting features and gave me some ideas.

First of all, here's a page with some pictures showing what the rifle looks like. Unfortunately, there aren't any closeups of the lifter or anything.

Now, to get to the point: as the lever is pulled down and forward, the bolt is pushed back. And, at a certain point, the carrier just pops up.

Note what I said in that last sentence. Rather than the carrier rising up during all, most, or even a part of the motion of the bolt, the motion happens all at once. Observing this, I hypothesized that either A.) there was liberal use of gear ratios involved, or B.) there was a spring involved.

I looked at an exploded view of the rifle, and couldn't make a whole lot out of it. However, I did notice that there was a part labeled "carrier spring" (or something like that, anyway).

So, that got me thinking: instead of having the bolt and/or pump directly move the carrier, why not simply have the pump at one point release the carrier to spring upward. On the way forward, the bolt can force the carrier back down and a catch would keep it there until the bolt is opened fully once more.

Edit: It suddenly occurs to me that this idea is fairly similar to NerfFreak's latest, but with the addition of a catch for the carrier. Also, the carrier pivots from horizontal to an angle (thus creating a ramp) rather than moving vertically like in NerfFreak's idea.

P.S. If necessary, I'll post some MS Paint diagrams later.

Edited by jwasko, 02 October 2007 - 05:13 PM.

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#311

Posted 02 October 2007 - 05:33 PM

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#312

Posted 02 October 2007 - 07:23 PM

I'm about 90% certain that the Winchester 94AE does not use gears and, and it's motion is independent of the action of the bolt and the lever except for one crucial moment.

This crucial moment is when the bolt releases the carrier from a catch, which allows the carrier to spring upwards.

Also, to emphasize: there are no gears involved in the motion of the carrier.

So, in conclusion:

Most Shotguns = gears

Your .22 = gears

Winchester (probably) = no gears

Your nerf shotgun = no gears, like Winchester (probably)

And now I go to make another MS paint diagram. I'll post it in 15-20 min. Then, I'm off the internet to study physics (hopefully).

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#313

Posted 02 October 2007 - 07:39 PM

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#314

Posted 02 October 2007 - 08:20 PM

#315

Posted 02 October 2007 - 08:43 PM

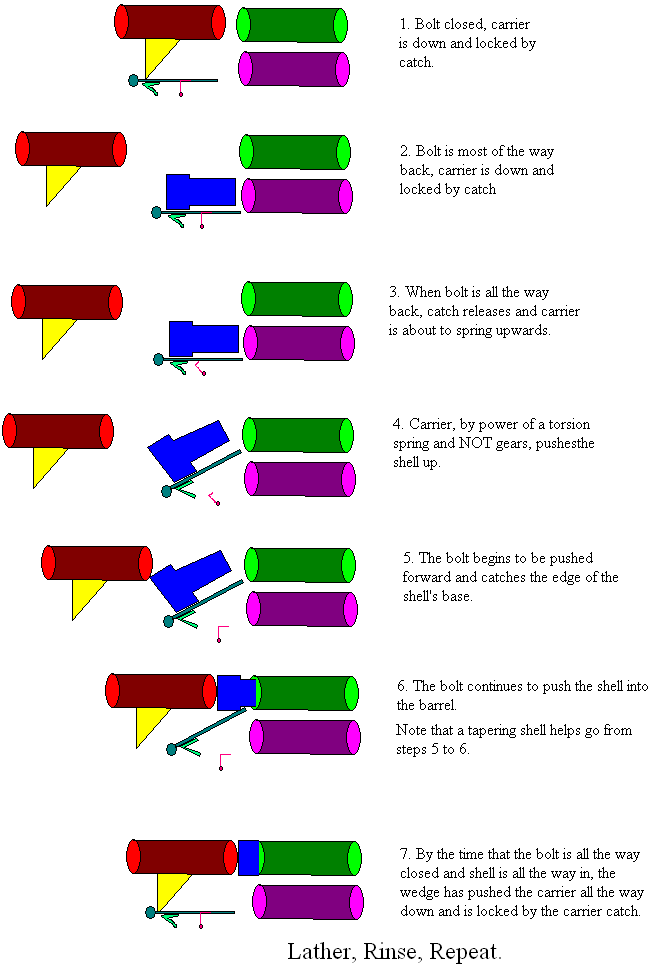

Well, it took a lot longer than I wanted it to, but it turned out pretty well.

Again, this is how I think (though I could be wrong) that the Winchester 94 works, and how you could potentially make your shot gun work.

Problems with this system:

1. Several moving parts make it more complex and thus harder to make and more likely to fail than some alternatives (like that ramp/track that Ronster posted)

3. Also, you kind of need cartridges that are taped and/or have a rounded head. I think the FAR had those, by the way.

Although, I'm not sure that none of the other ideas hear need a similar cartridge.

So, instead of a ramp thing, you may be better off using straight, vertical lifter. And no, I am not making another diagram of that (at least, not tonight). Just replace the angling lever with a block that moves up and down (and still locks and releases the same way as in the above diagram) in your mind. The use of a block would also (I think) solve the problem of having to stop the other shells in the mag.

Edited by jwasko, 02 October 2007 - 08:48 PM.

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#316

Posted 09 October 2007 - 07:37 PM

I'm guessing being the first person to pull off a tube magazine was one of the main points of building the gun. More power to that, if you can make it work.

I thought the magazine for the SCAR-N could have been better. AR-15 parts are expensive AND the cartridges were "single stacked" If the tube magazine concept falls through, you could build (rather than use an AR-15 clip) a redonculously high-cap box magazine by widening it enough to stack two rows of cartridges.

Keep up the good work.

All your base are belong to us!!"

{Presbyterian College Nerf}

#317

Posted 09 October 2007 - 07:46 PM

The other advantage of using CPVC shells is being able to shorten the cartridge length from 2.5" to 2" because the rim can be moved forward. This will result in a small overall gun, and a higher magazine capacity.

jwasko: That design might work if I could place the torsion spring in such a way that it didn't block the loading port. Diagonally, perhaps? The other problem is that the tab on the bolt will have to travel about 4" with the bolt carrier. That's not ideal for a compact-as-possible gun.

Edited by SHADOW HUNTER ALPHA, 09 October 2007 - 07:53 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#318

Posted 09 October 2007 - 09:03 PM

The loading port...forgot about that...

I'm not sure what "diagonally" means, but, I suppose it could work.

Or you could find some other way of springing it up Some sort of band could work, but is liable to break (which would be bad in a war). By the way, the spring in the Winchester that I saw in the exploded view was basically a torsion spring (in function, especially), but really was just a V-shaped, springy piece of metal.

Now, I don't want to make you change your whole design, but:

On most (if not all) lever-action, tube-magazine firearms (including shotguns), the loading port is on the side rather than the bottom. This may solve the problem of the loading port-carrier conflict, but then again it could bring a up a host of new problems (I can't think of any, but I'm sure someone will find one sooner or later).

The other problem is that the tab on the bolt will have to travel about 4" with the bolt carrier.

I'm not sure what you mean...What's the bolt carrier, exactly? But otherwise...is a couple of inches (give or take) worth it in order to (potentially) complicate things greatly? You'll have to make decisions like this if you want to get the thing done and keep it fairly reliable.

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#319

Posted 09 October 2007 - 09:29 PM

The bolt carrier is the white tube that serves as both the plunger tube and the housing for the bolt (The bolt is only the small section of PVC with the triple-lug locks attached to it. The bolt carrier is the long 1" I.D. PVC tube that holds this bolt.). If the travel is over 2" long, it risks hitting the fire control group. I may be forced to use gears on this one if a solution cannot be found. I could theoretically replace the wedge in your plan with a solid steel rod about 3/8" thick for the same results, and just round the tip. That way, the results are duplicated while there is not such a great mass being moved across the carrier. I'll have to see hot it fits in.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#320

Posted 09 October 2007 - 09:56 PM

Note: .410 is the smallest common size of shotgun shell.

Ah, yes, I see, that bolt carrier.

Also, that triangular thing that I put in there was mostly just a quick solution; your idea sounds good. In fact, maybe there's a way to get that steel rod to fold up on the backward stroke of the bolt then come down going forward. The main problem would be getting it to push the carrier down rather than just folding back up, if you know what I'm saying.

I'm still not completely sure about which way is "diagonal," but it's fine. You can tell better than me how the spacing will work out. And (in this case, anyway) as long as you know what you mean, that's good enough.

If you'll excuse me, I have to go retype two very long emails because my email account signed out before I could send them.

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#321

Posted 09 October 2007 - 10:11 PM

By diagonal, I am referring to the plane that bisects the loading port and carrier as the straight, or "normal" way. Diagonal would mean that the torsion spring would be placed at an angle, either 35 or 45 degrees, to this line. The spring would form a line at an angle with the plane if the gun were to be pointed at you muzzle-first. That's not a good explanation, but I try to give a little more. I want to angle the spring so that the long, straight wire portion of the torsion spring is not blocking the loading port on the bottom of the magazine. It would have one side bordering the loading port, and the other connected to the carrier so that the loading port is not blocked. I could also cut the spring to make it much simpler, and I will probably end up doing so anyways. I can post an MS Paint diagram tomorrow if need-be.

As for the rod folding up into the bolt carrier, I personally wouldn't tinker with it. The bolt carrier isn't thick enough to support it without wrecking the plunger seal, and finding a way to execute it would mean more springs and pivots. If it were easier to construct without the threat to the seal, then I would attempt it.

Lastly, does anyone know the effects on a dart's velocity when it is transferred from CPVC to brass? I would assume that it would speed up without the threat of fishtailing, as brass is a looser and smoother material, but I want to make absolute certain before I design the simplest shells possible and threaten efficiency.

Edited by SHADOW HUNTER ALPHA, 09 October 2007 - 10:14 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#322

Posted 09 October 2007 - 10:42 PM

Yeah, you're right about the folding...keep it simple, Jwasko, keep it simple...

As to CPVC to brass, I don't foresee any problem; it should be similar to going from 17/32" brass to 9/16" brass, with the change in material not having any detrimental effect. Like you said, it's only a transfer from a rougher to a smoother material. I don't know that it will actually speed up, though. Well, actually the dart is accelerating the whole time the air (and, by extension, the plunger) is pushing it.

One word of caution, however: I left some stefans in (un-bored out) CPVC for some time. Now, they fit perfectly in that CPVC but are loose in 9/16" brass, instead of perfect in 9/16" brass like they had been. Of course, that was for quite some time, but still...

Finally, I just realized a bit of a problem. Okay, it's actually a major one if you want to load from the bottom while the bolt is closed. In the Winchester-type design that I posted and even (I think) other previous ideas, the carrier will be down and in the way while the bolt is closed.

Now, unfortunately, I can't really remember how a pump-action shotgun works as far as when you can load. Isn't the little door over the loading "gate" also the shell carrier? I think it can move up and down when ever the bolt is closed, thus allowing access to the magazine tube. With the Winchester design and (I think) even those carrier-on-a-ramp type designs (see Ronster's post, page 18), you can't do that.

Of course, you could (maybe, I'm not sure) still load when the bolt is open.

But, if I'm correct that this is a problem, I may have a solution. But it's going to take too long to draw and explain to do it tonight. Maybe I'll do it tomorrow morning, depending on when I get up (hooray for cancelled classes!).

Now, I'm going to try to force myself to log off the Haven and sleep, or do homework.

...Must...have...willpower...

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

#323

Posted 09 October 2007 - 10:45 PM

AWESOME NITEFINDER

#324

Posted 10 October 2007 - 05:45 AM

jwasko:

Theoretically (need to find a synonym), I could also move the peg that keeps the carrier down.If I were to widen the carrier a bit, the peg could rest on the left edge and a loading port could be cut into the right side. However, the problem is that the carrier must still have unobstructed access to the feed port (not the loading port; the feed port is the slot that shells travel through from the magazine to the breech). I could probably get away with something like this. I didn't want to lose the bottom-loading feature, but this idea lends itself so well to a side-loader.

Edited by SHADOW HUNTER ALPHA, 10 October 2007 - 05:45 AM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#325

Posted 10 October 2007 - 09:58 AM

But, I just want to make sure that you got what I said: I'm pretty sure that, outside of the gear-driven method used in real shotguns, I don't think that any of the ideas in this thread would work as far as being able to load from the bottom of the shotgun...especially when the bolt is closed.

-Jwasko, STILL Sole Surviving member of Steel City Nerf and Sober Sister of the Sex Dwarves

We NERF ON all day, and FUCK OFF all night

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked