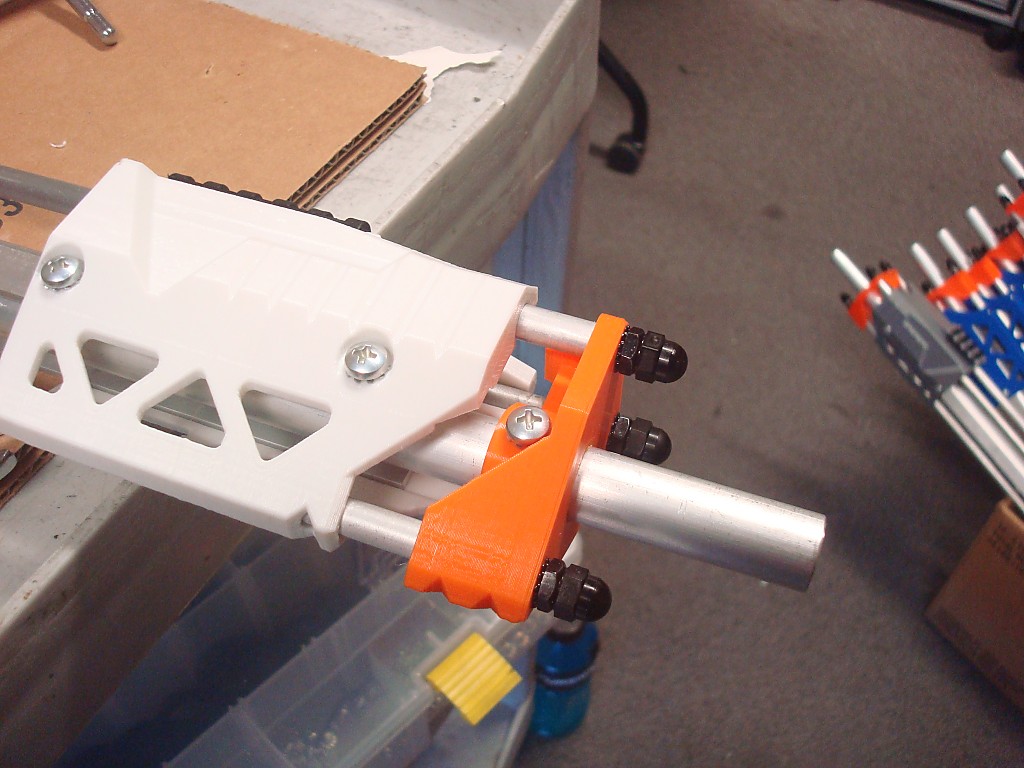

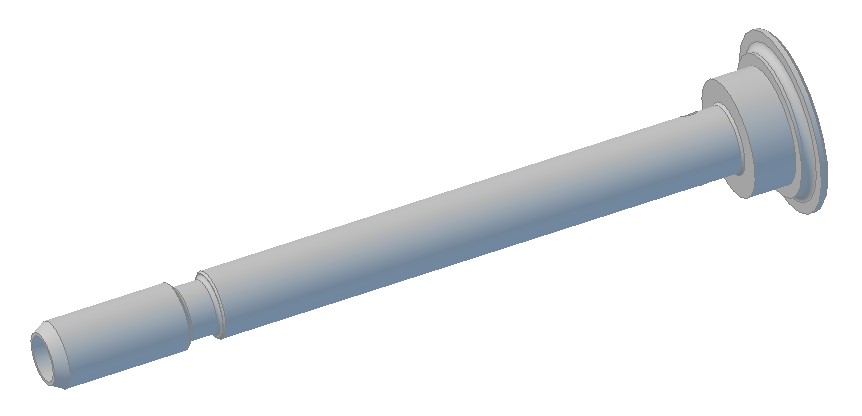

It was a few small issues that combined to make a single annoying problem. The proportions of the cast P1b part was squeezing the skirt seal out a bit making it tighter in the plunger tube. At some point the stock core part got moved backwards in the Butt piece to overcome the shortness of the included screws. And potentially the lip of the Butt piece I printed wasn't quite long enough either.

All of the above meant that the plunger could travel a bit too far backwards on prime, and the skirt seal was expanding so that it rested onto the back lip of the plunger tube. I suspect that all of the above are largely the result of using parts that are mixed and matched among a few revisions. Replacing P1 and P2 with the newest files helped a bit, then moving the skirt seal forward on the assembly made the issue disappear completely.

All of that said I have an updated file set.

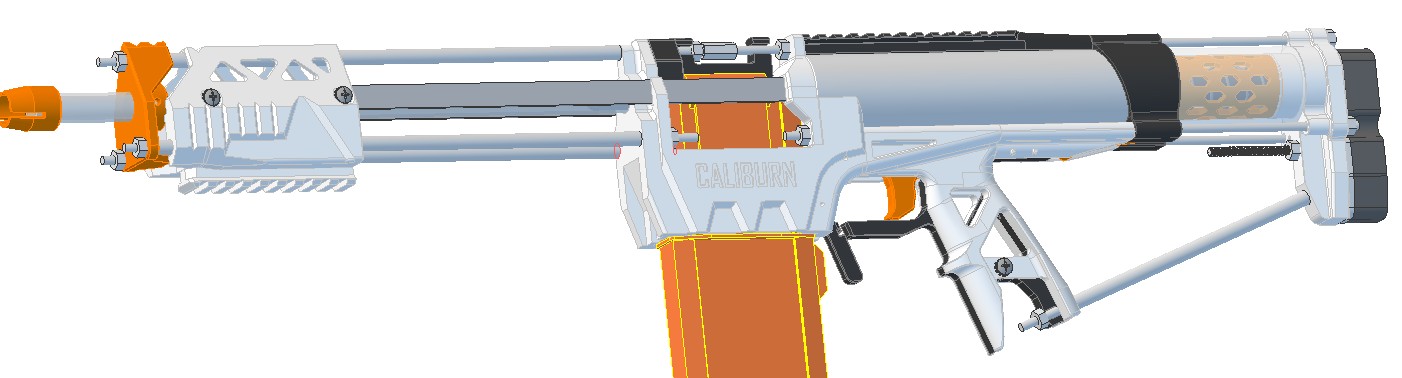

CHANGE NOTE 07/11/17: Updated P1 and P2 to move skirt seal 1/8" further forward to remove potential for it to be primed beyond the aluminum plunger tube.

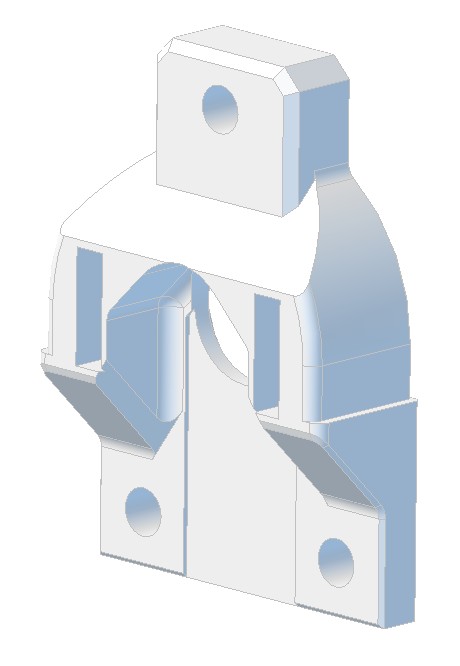

Reamed out a few parts to improve assembly consistency, strengthened P3b.

Parts should now print with all holes to tolerance so that post-drilling will not be require prior to assembly.

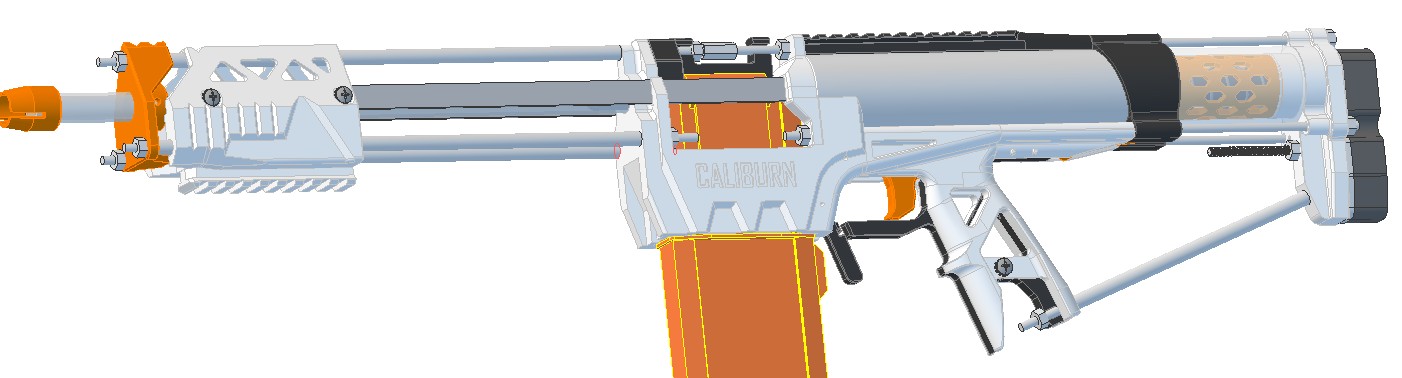

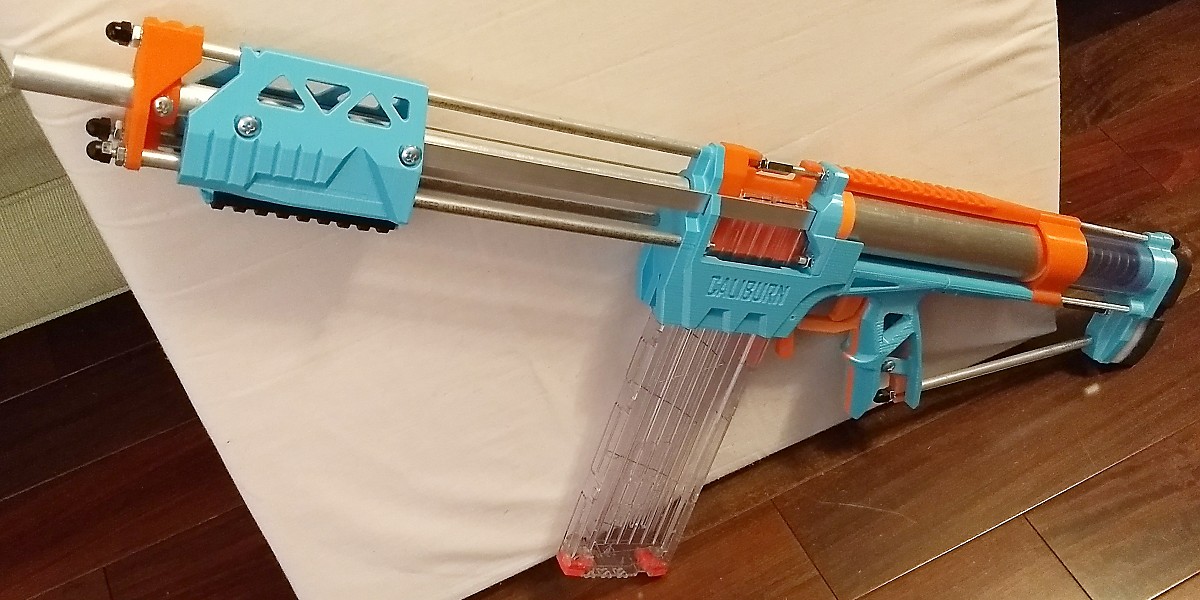

Also included some optional parts such as alternative grip plates, ring that center the 1.5" OD plunger tubes in the 1.66" ID features of the part, a foregrip with fewer rail segments, and a non-cushioned buttplate. Muzzle can now be tapped for 10-32 screws to retain the barrel if you want to avoid gluing the barrel to it. Muzzle Brake piece has been corrected to match the ID of Muzzle and Magwell parts.

The "Skeleton" grip plates are in the Optional parts folder.

Updated STEP and STL files are available now.

https://www.thingive...m/thing:2376150

I am VERY FAR BEHIND on the waitlist for completed blasters. I am however keeping up with the hardware kit waitlist.

CHANGE NOTE 07/13/17: Fixed length error in P1B part

Edited by CaptainSlug, 13 July 2017 - 04:13 PM.

The little critters of nature, they don't know that they're ugly. That's very funny, a fly marrying a bumble bee. I told you I'd shoot, but you didn't believe me. Why didn't you believe me?