SNAPbow Mk. V.

Materials Needed:

Main Blaster Body:

1’ 1 ¼” sched. 40 pvc

6” ¾” sched. 40 pvc

1”x½” bushing

Handle/Stock:

#8x1 ½” screws (2)

1x2 Poplar board (or the handle material of your choice)

¾” poplar (or matching) dowel

½” pvc tee OR elbow

½” pvc 45

Trigger:

Industrial-strength clothespin

Roofing nail

4” zip ties (2)

8” zip tie

1 ½ “ angle bracket

Plunger Assembly:

Superlative plunger head (http://nerfhaven.com...showtopic=18314)

1 1/2" cpvc endcap

2 11/4" OD steel fender washers

1 appropriately sized nylon spacer (look at the photo)

1 #6 11/4" bolt

1 11/4" rubber fender washer

1 11/2" rubber fender washer

1 #8 finishing washer

1 #6 wing nut

1’ of ½” cpvc

½” cpvc T

¾” pvc endcap

[k25] OR Plusbow spring

Adhesives, screws, and so on:

Epoxy Putty

CA glue/Solvent weld

Goop

Hot glue

#6 ½” pan head sheet metal screws.

Main Body:

Wrap your 1” bushing in etape until it fits reasonably snugly in the pressure chamber (PC hereafter). Slather it with goop and seat it. Anchor it with 3 screws. Cut your ¾” pvc like so, grind it to fit your zip tie, and glue it along the top of the PC. I like hot glue followed by goop, but epoxy would also do fine. Drill a hole 3 ¼” from the rear of the PC for your trigger pin (4” if you’re using a plusbow spring). Wrap your ¾” endcap in a bit of tape, slide it into the PC until it’s pretty much flush, and drill a hole in each side. These screws will be how you disassemble the gun.

This photo doesn't feature the groove/zip tie, but you get the idea.

Trigger Assembly: Cut your clothespin down, fill with epoxy putty, drill, and assemble--pretty basic stuff. Make sure the pin is cut long enough; the superlative head fit’s the PC more loosely than does a traditionally made SNAP head, and a too-short pin is an invitation to catch slippage. Zip-tie the trigger on. No glue is necessary, although gooping it on is fine too. Fit a bit of cpvc over the angle bracket, or glue a block/randomly selected bit of flotsam to the handle to prevent overtravel.

Make your superlative plunger head. Mount on your plunger shaft, using 2 screws or a pin. Add your spring, drill out your ¾” endcap, and add your handle. Lubricate with silicone grease, and nothing but silicone grease. Assemble, add a barrel, and shoot people.

Handle and Stock:

Pretty self-explanatory. Make your handle, Carbon-style. You’ll need to grind/gut a groove for the screw heads to fit into. Pop it on, lift it up, and glue it down with high-guality CA glue/solvent weld. Super, super solid. Also a major pain in the ass to get off if your handle fails, so make sure your handle is built properly. Conversely, you can anchor it with 4-5 screws as shown

It will just take longer to disassemble.The handle should be butted against the back of the trigger, holding the trigger in place.

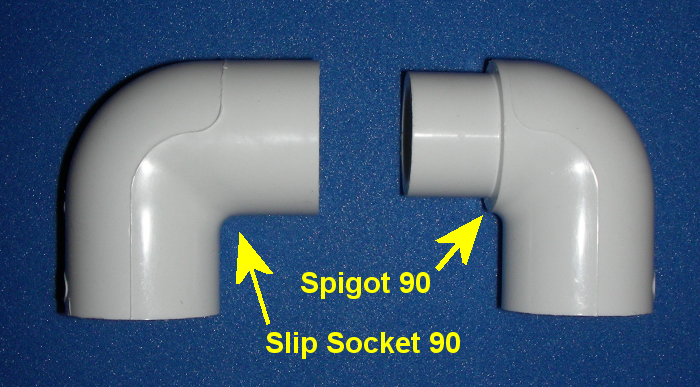

Cut a dowel to the proper length for your stock, bulking it out as needed with etape. Add fittings as shown and screw it down.

Plunger Assembly:

Maintenance: Re-lube infrequently. Pull the plunger and wipe it down occasionally, to remove any accumulated grime. I recommend priming by holding the foregrip in your non-dominant hand, and pulling back with your dominant hand. Use a long, tight barrel--I use 16” of cpvc, lubricated with silicone spray.

Edited by rork, 05 March 2010 - 10:03 PM.