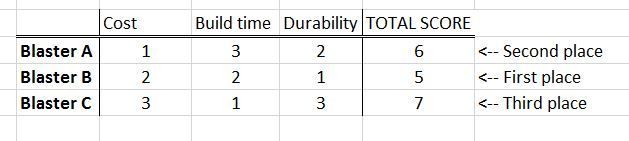

So my distaste for omnidirection plunger rods is not unknown to the nerf community, up til now, they seemed to catch less reliably than unidirectional catches, and were overall more fickle. The problem comes down to spring binding issues, particularly with the [k26], and maybe even the [k25]. As the plunger rod is pulled back and the spring compresses, it does not compress perfectly in line with the plunger rod, and tends to "serpentine", getting all wavy and kinky before it reaches it's final stage of compression. During this time, the spring gets caught in the omni-directional catch part of the plunger rod (with the lower rod diameter) and produces either a VERY unpleasant "crunchy" feeling to the prime, and often results in a "false catch" where the spring actually gets caught in that catch region when you pull the plunger rod back. You think the catch has engaged, and as soon as you begin to let go, and the spring is able to exert it's energy, the plunger assembly flies forward. This leads to swearing, sore fingers, questioning your rainbow catch-making abilities, and an overall hopeless feeling knowing that this lifeless piece of plumbing pipe has defeated you. You're better than that mate. Millions of years of evolution have prepared you for this moment. It's time to take on that omnidirectional plunger and make it yo bitch.

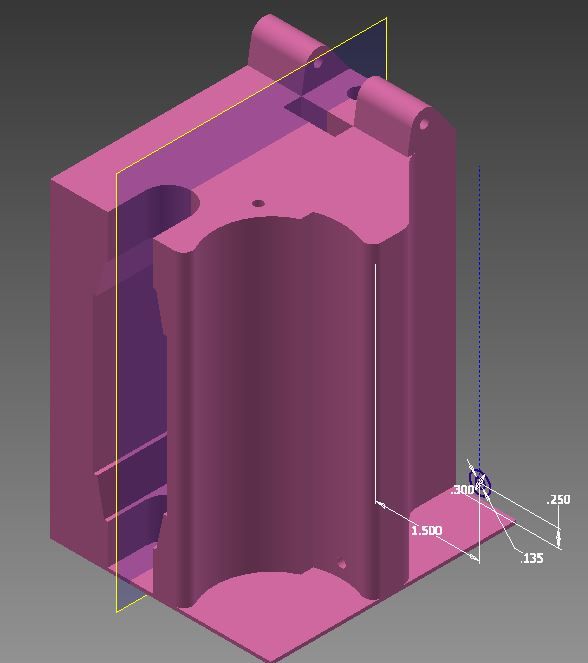

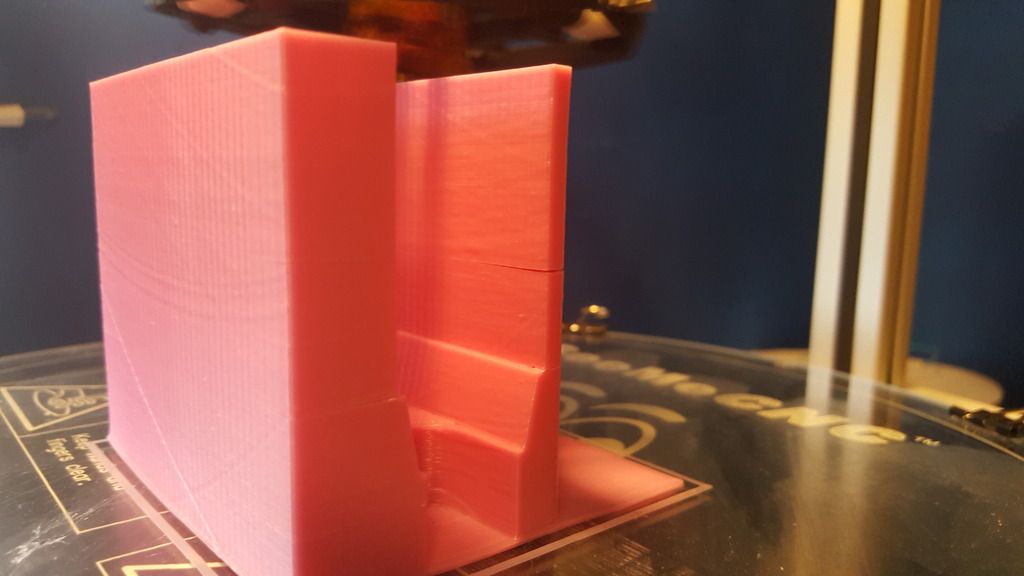

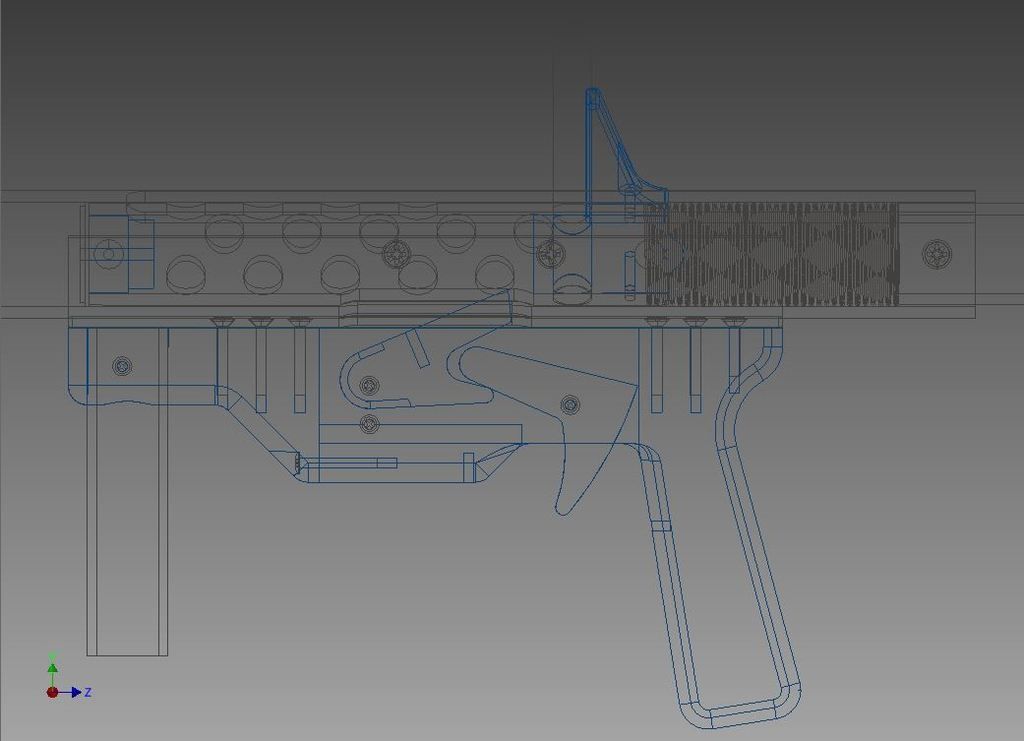

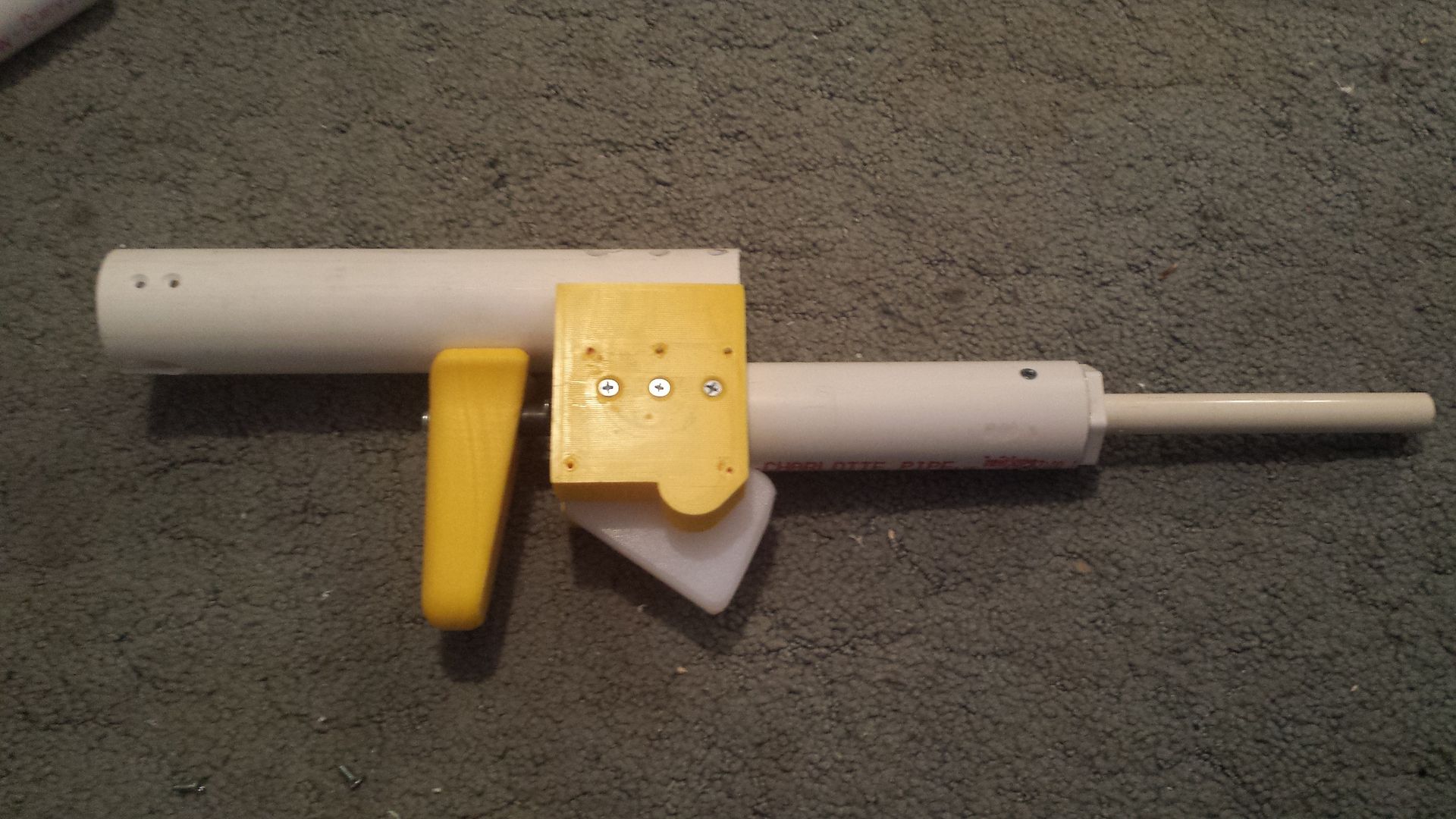

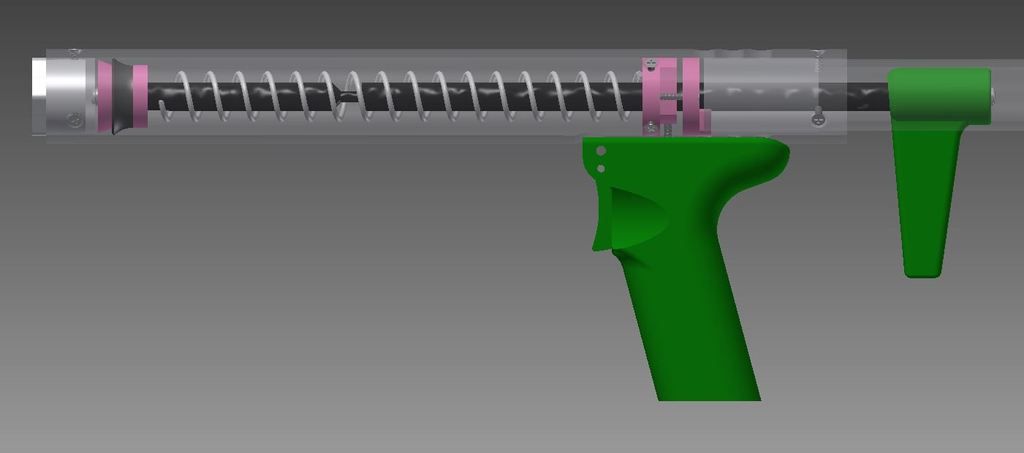

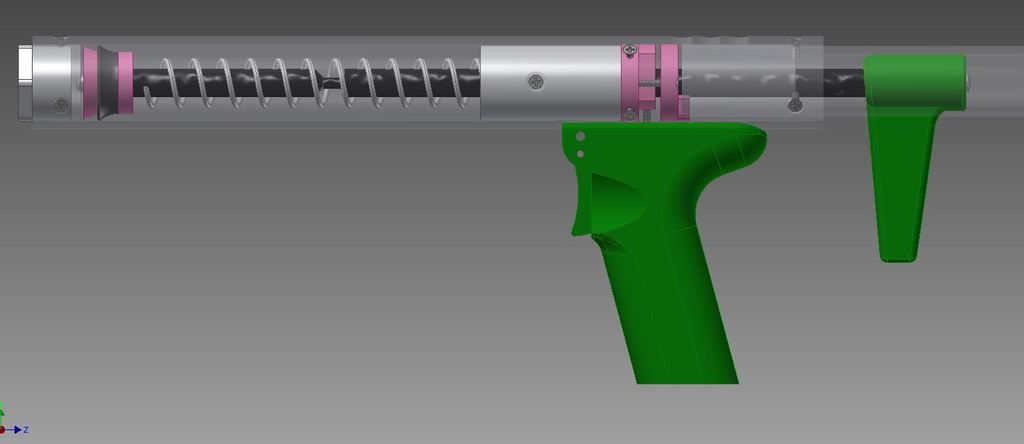

The "Before" photo. Here is a pullback with the main tubes "ghosted" out, so the insides are visible but you can still see the outline of the body tube. Typically, the spring binds in the recess near the front of the plunger rod, where it is supposed to engage in the catch.

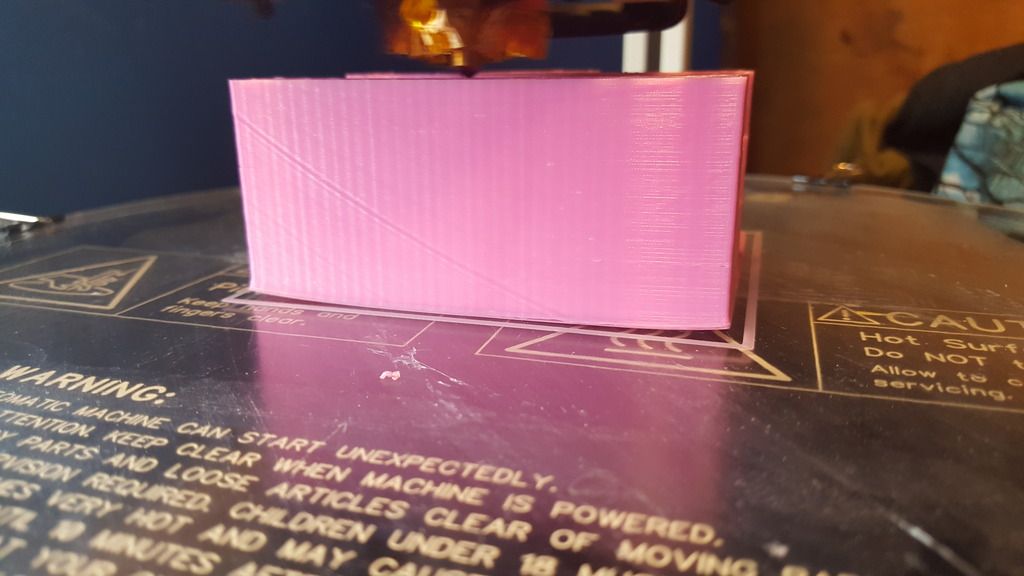

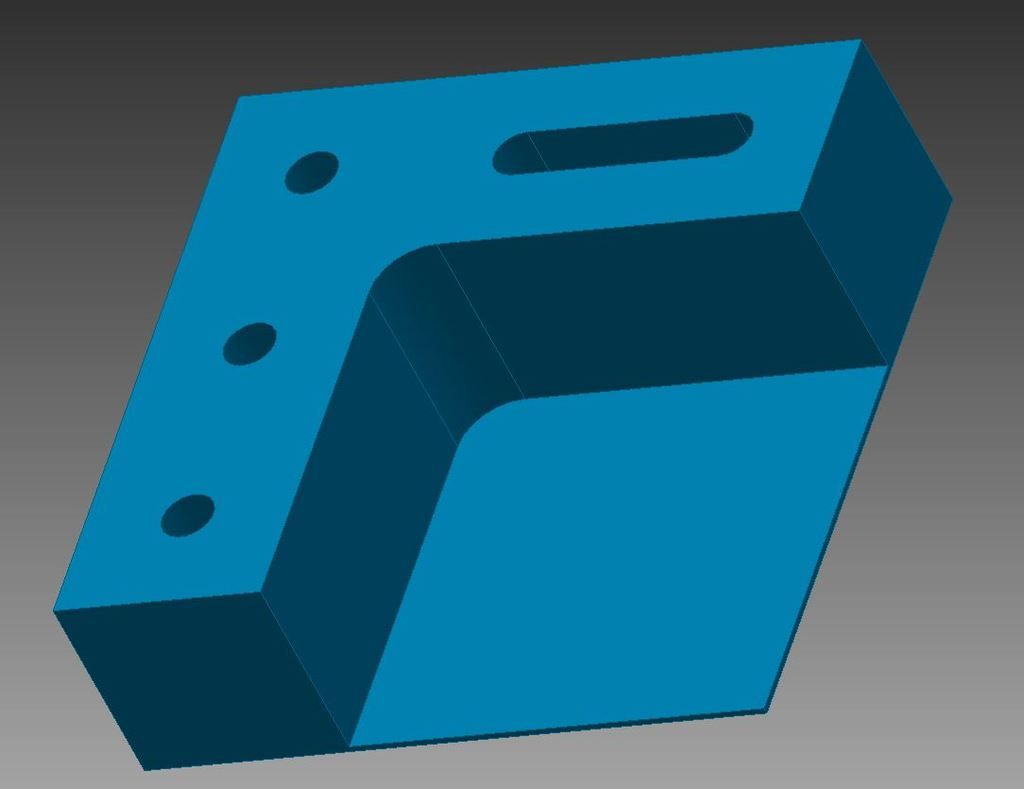

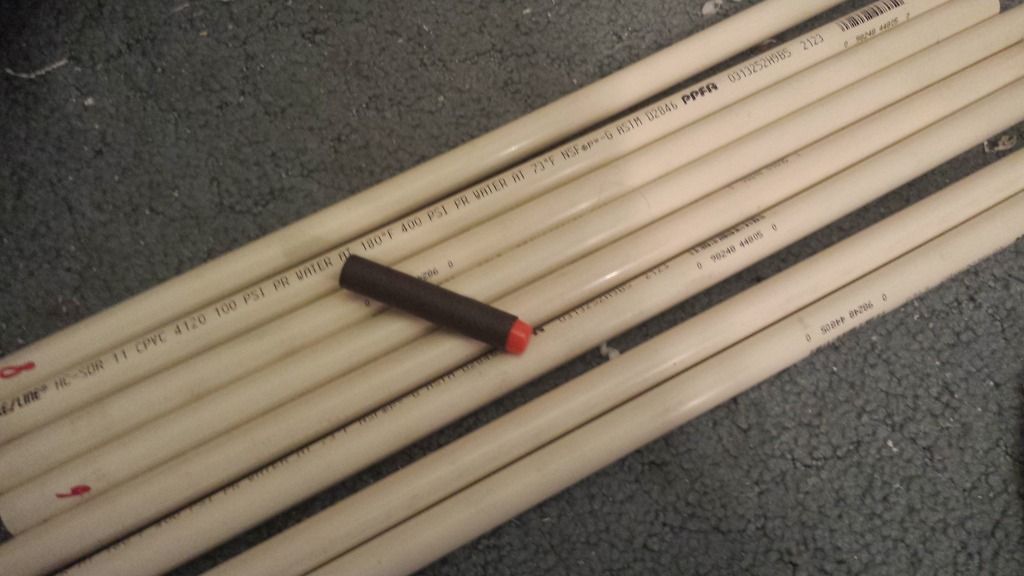

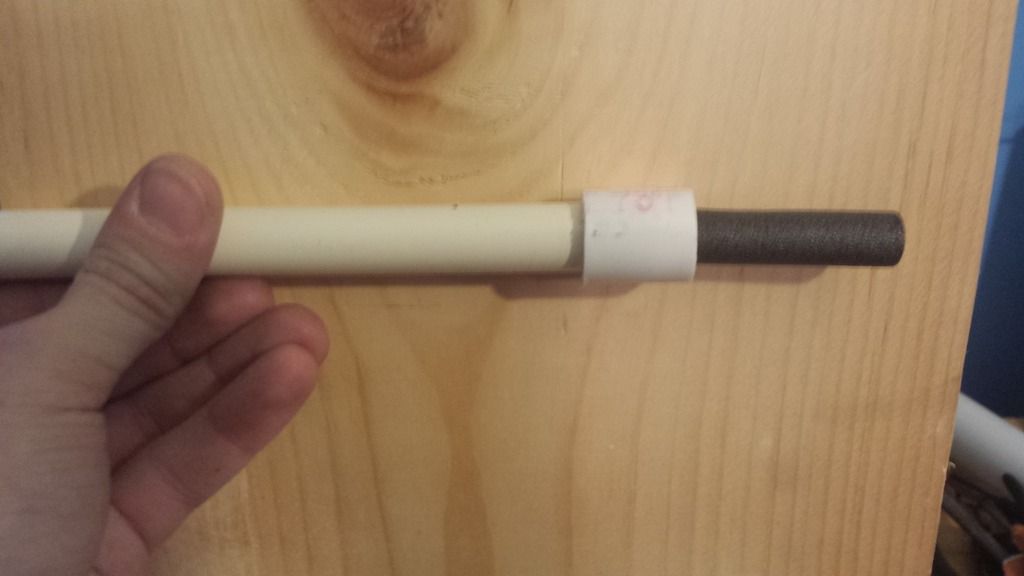

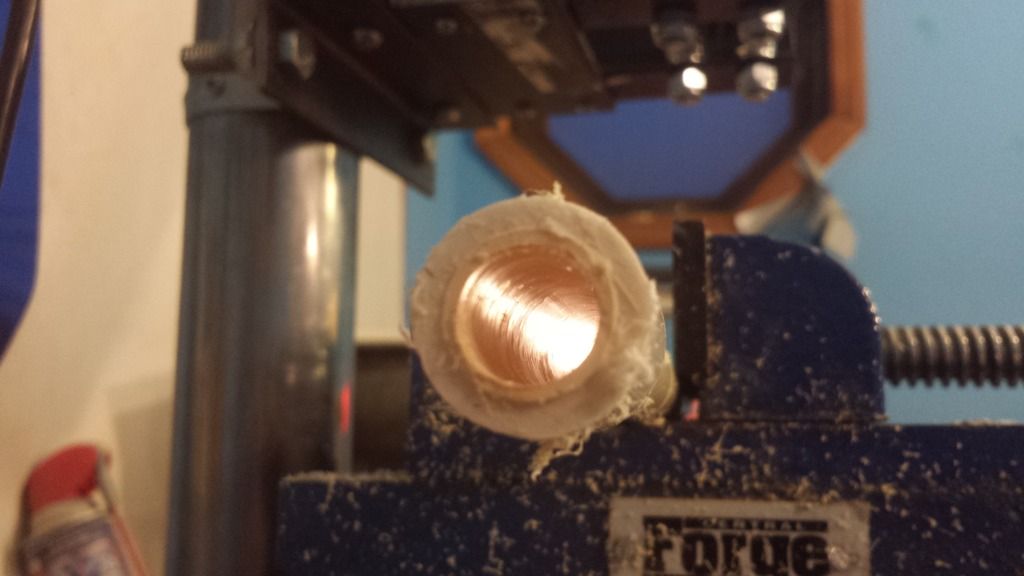

This is it. This is the easiest solution ever. Cut a piece of 1" PVC Pipe, about 2.5 inches. Make sure it is shorter than the spring at full compression, but not too much shorter. Get it close, but make sure it is still shorter. Take note that the front (left side of the photo) of the tube is beveled on the inside. This is important. Put a few wraps of packaging tape around this so it fits fairly snuggly inside the 1-1/4" PVC plunger tube.

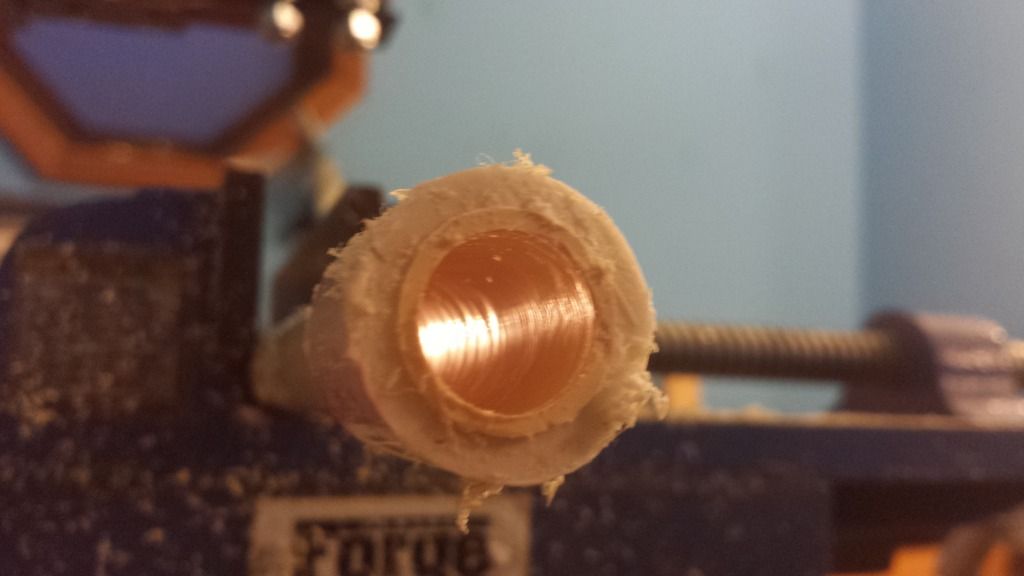

Boom. Throw it in there. Rest this piece against the front of the rainbow catch, with the beveled end facing forward. Sink two screws in there to hold it in place.

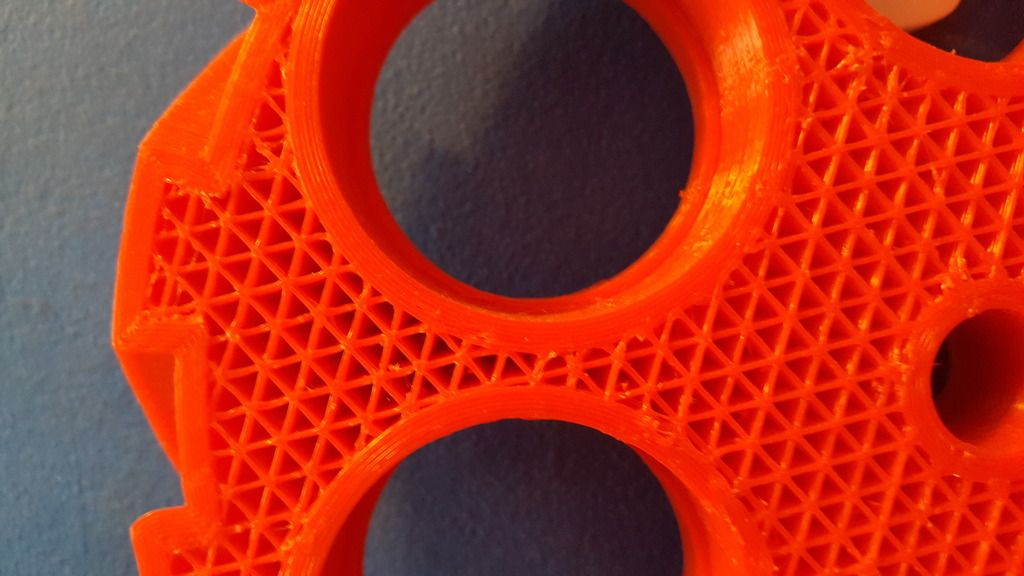

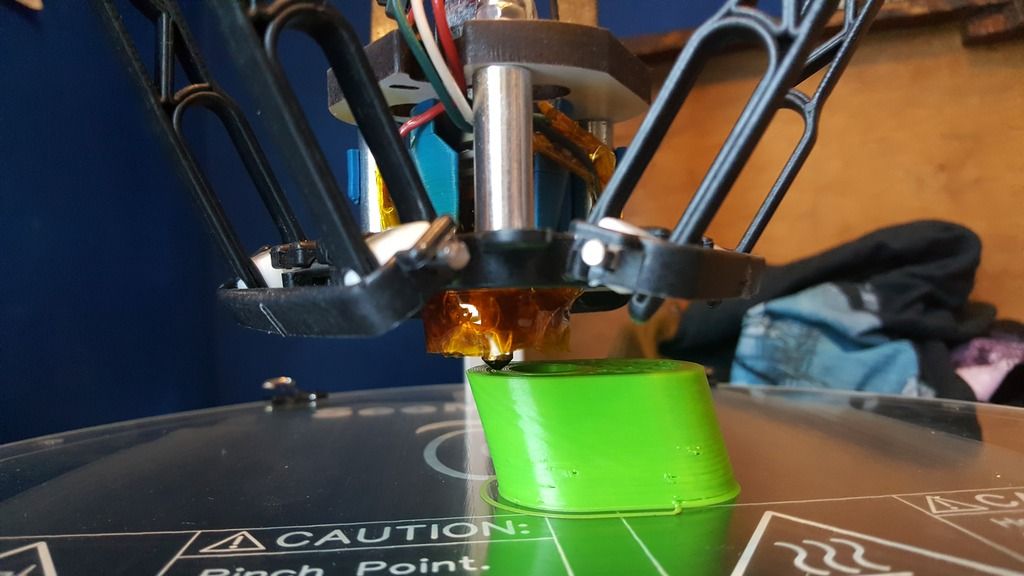

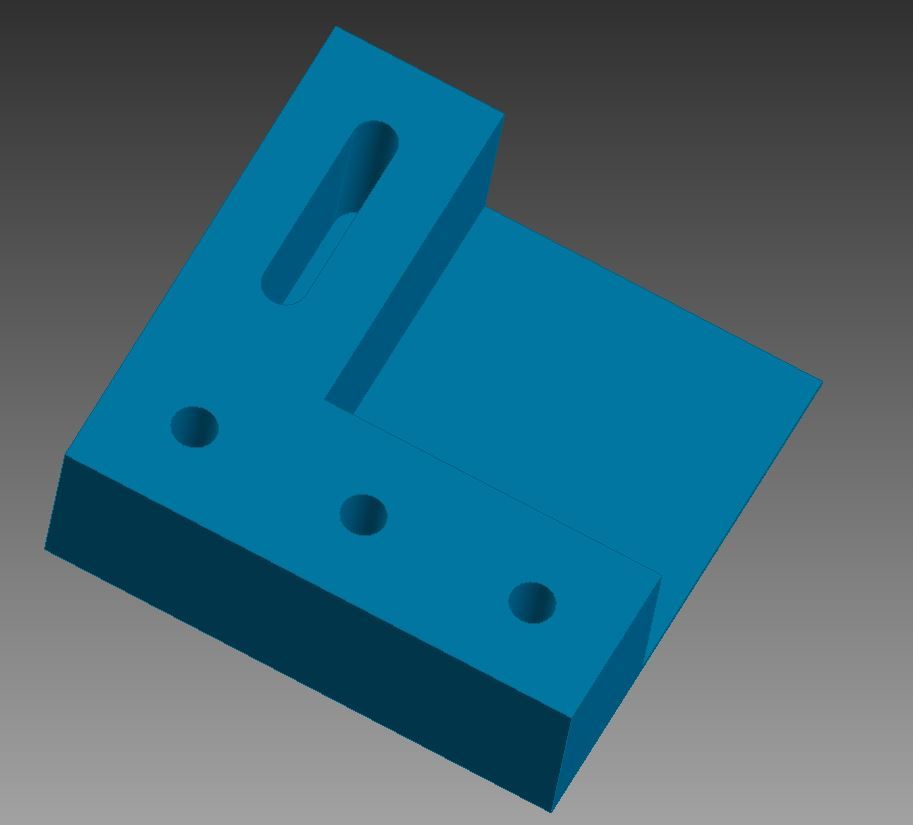

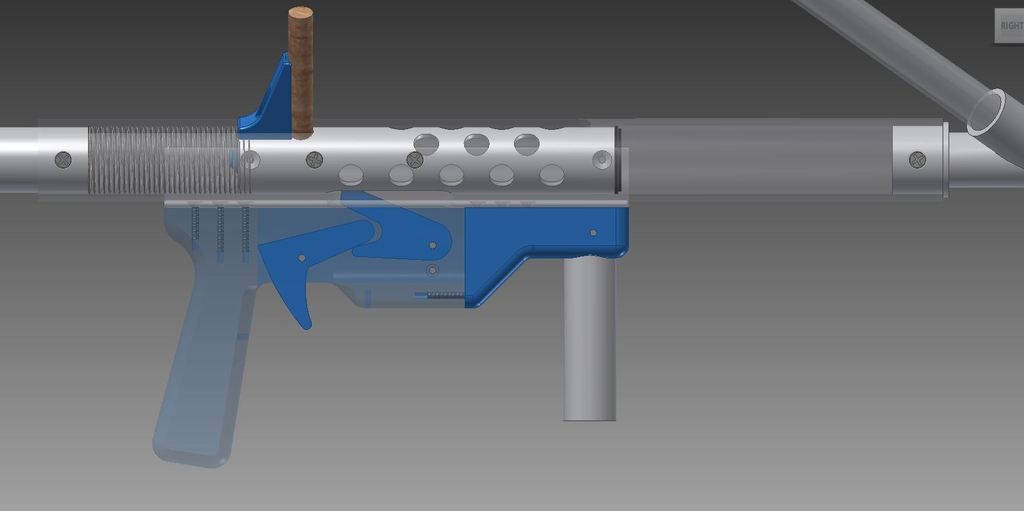

This photo provides a little more insight, the anti-binding pipe goes around the spring. When the spring is compressed, it is "guided" to a more "cocentric" position within the body tube. The bevel smoothly pushes any parts of the spring that may bulge out into position, so the spring cannot bend to the point where it would interfere with the catch region of the plunger tube. After installing this into a rainbow pistol/carbine (5 inches of draw, like 1 to 1.5 inches of precompression, 10 inches of [k26] spring) all false-catches stopped completely. The prime was smoother, and all the problems I was having with the catch vanished. It caught every time, and smoothly. Follow this guide if you're using a [k26] in conjunction with an omnidirectional plunger rod.

Make sure it doesn't cover up your speed holes (anti vacuum holes). Once you sink in this piece, just re-drill the speed holes in the main body tube through the anti-binding pipe you just installed. Super easy.

Posted by

Posted by