#126

Posted 11 June 2006 - 05:09 PM

#127

Posted 11 June 2006 - 08:16 PM

The ID is a little too small for a custom boring rod being any easier than just using a drill bit.Ever consider making your own tooling? Err...it's only for plastics anyway, so why not?

The drill bit isn't THAT expensive ($26). I just have compounding problems of not having the health or time to work on everything I want to right now.

Edited by CaptainSlug, 11 June 2006 - 08:29 PM.

#128

Posted 20 June 2006 - 12:25 AM

I don't really have any on topic contribution but keep up the good work.

(are you captain slug for bit-tech.net?)

#129

Posted 20 June 2006 - 06:34 AM

Yep. My computer-related projects are delaying my nerf-related projects.(are you captain slug for bit-tech.net?)

Edited by CaptainSlug, 20 June 2006 - 06:35 AM.

#130

Posted 21 June 2006 - 04:59 PM

Yep. My computer-related projects are delaying my nerf-related projects.(are you captain slug for bit-tech.net?)

Finish Mk6 modular first jeez! And finish your waterblock for procooling too!

lol, sorry, I just found it interesting that we're both on bit-tech, procooling and nerfhaven.

#131

Posted 28 June 2006 - 11:20 AM

how is the progres?

i like the idee. hope it will turn out very good and cool.

#132

Posted 28 June 2006 - 08:11 PM

I'll get back to Nerf in a month or two when I'll have more resources, time, and money.

Edited by CaptainSlug, 28 June 2006 - 08:12 PM.

#133

Posted 29 June 2006 - 08:36 PM

#134

Posted 29 June 2006 - 10:04 PM

#135

Posted 30 June 2006 - 07:00 AM

There's several dozen more images in the forum thread: http://www.ocforums....ad.php?t=394139What mother board is on there and what do you ahve on the mother board? I can't see for the metal casing bars.

It's an Aopen NCK804Ua-LFS. Rock solid and gorgeous motherboard.

It's covered by two decorative covers that will also help me hide some wires I have yet to add for lighting and possibly a temperature probe.

Edited by CaptainSlug, 30 June 2006 - 07:07 AM.

#136

Posted 30 June 2006 - 08:49 AM

#137

Posted 30 June 2006 - 11:13 AM

on guns with a clip under the barel you need a spring to push the darts up.

but it is very hard to find the right spring because they must push them up, but they may not compress them.

thats why they use shels.

if you use a top fed hopper design, they won't compress so you don't need them.

the weight of the darts will be enaugh to push them down in the gun.

hope this was enaugh.

greats

#138

Posted 30 June 2006 - 03:03 PM

I abandoned the idea of using shells because I don't have a spring-feed system where dart compression would be an issue. The darts roll in the hopper towards the inlet thanks to gravity

Edited by CaptainSlug, 30 June 2006 - 03:07 PM.

#139

Posted 03 July 2006 - 08:17 AM

edit: also might as well point this out. Half feeds and misfeeds might result in "chops" like in paintball or maybe just jams since the velocity won't be insane. A positive feed system would help reduce that too.

edit 2: I'd say that a friction feeding system would be the best idea. Maybe just a rubberized drum that lines up darts and pushes them into the feeding position. You could also power it off the motor if you get clever with it.

Edited by footemps, 03 July 2006 - 08:39 AM.

#140

Posted 04 July 2006 - 06:42 AM

#142

Posted 05 July 2006 - 05:25 PM

Some type of follower in the hopper wouldn't be a bad idea, but I'm pretty confident that it would work well without it.

Sincereley,

Pat

#143

Posted 09 September 2006 - 12:37 AM

Assuming of course that my body will cooperate. Which it hasn't for the past two months.

Edited by CaptainSlug, 09 September 2006 - 12:39 AM.

#144

Posted 12 September 2006 - 01:30 PM

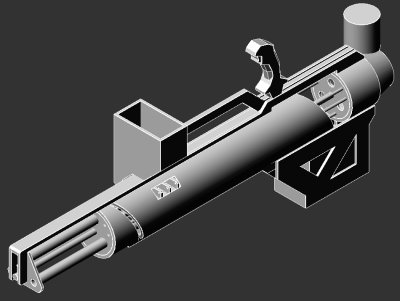

This is the shoe and slide mechanism that will slide the breech open and closed. The "shoe" is the green part that will bolt onto the arm extending off of the breech/barrel. Each shoe will have a wheel on top of it so that the helical track will push the shoe forward or back.

The yellow rods (1/4" aluminum) act as a guiding rail system.

The same mechanism will be used for the plungers as well.

And with all of the above figure out I have a much clearer image of what is left for me to do to make this gun operational.

Edited by CaptainSlug, 12 September 2006 - 01:38 PM.

#145

Posted 12 September 2006 - 07:10 PM

#146

Posted 12 September 2006 - 11:34 PM

Got Nerd?

#147

Posted 13 September 2006 - 12:24 AM

This was a concern very early on and I left three ways of clearing jams that won't require complete disassembly of the gun.Do you have a very effective way to clear jams? If not that might be a major hinderance to the guns preformance

1) The dart ramps which you can see sticking out of the left side of the gun in the above image and be removed from the gun to allow easy access to clear jams if they occur.

2) The forward breech track will be slide mounted so that you can move it out of the way, allowing you to manipulate the breech actuation by hand.

3) The dart hopper will be bolted into place, but can easily be removed completely from the gun by undoing the two screws that attach it to the upper frame spine. This gives you an even larger jam clearing window.

If you do all three you've removed all of the moving parts that could possibly cause a jam. And if I simply use thumbscrews to hold those parts in place it can all be done without needing any tools. I don't think jams will occur if the design of the hopper is such that the darts can only enter in the correct orientation.

Edited by CaptainSlug, 13 September 2006 - 12:28 AM.

#148

Posted 13 September 2006 - 09:31 AM

-Nerfer34

You know what... I know it's kinda late... but Props Cole.

-Baghead

#149

Posted 13 September 2006 - 03:24 PM

Good luck with it, I'll probably d/l the CAD drawings and get my school to install Alibre on their CAD/CAM machines...

And, don't shoot near windows with it. If the trigger got stuck on you'd be much poorer... stefans are expensive

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked