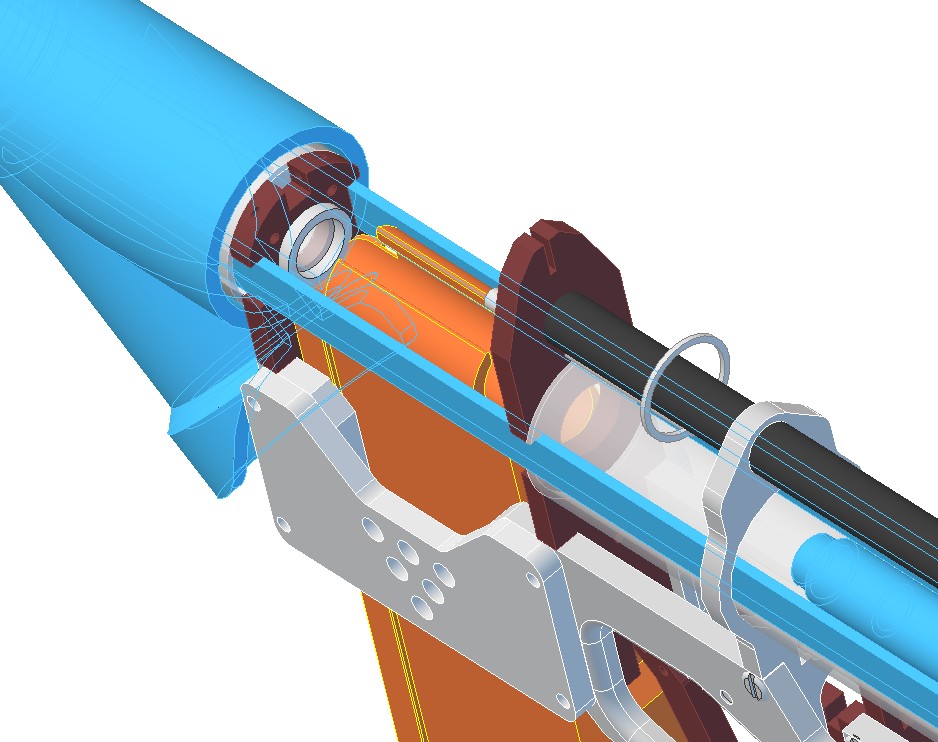

http://captainslug.c...3DPAssembly.pdf

http://captainslug.c...DPAssembly2.pdf

http://captainslug.c...DPAssembly3.pdf

https://www.thingive...m/thing:2376150

Partslist

http://captainslug.c...HardwareKit.gif

http://captainslug.c...ardwareKit2.gif

http://captainslug.c...ardwareKit3.gif

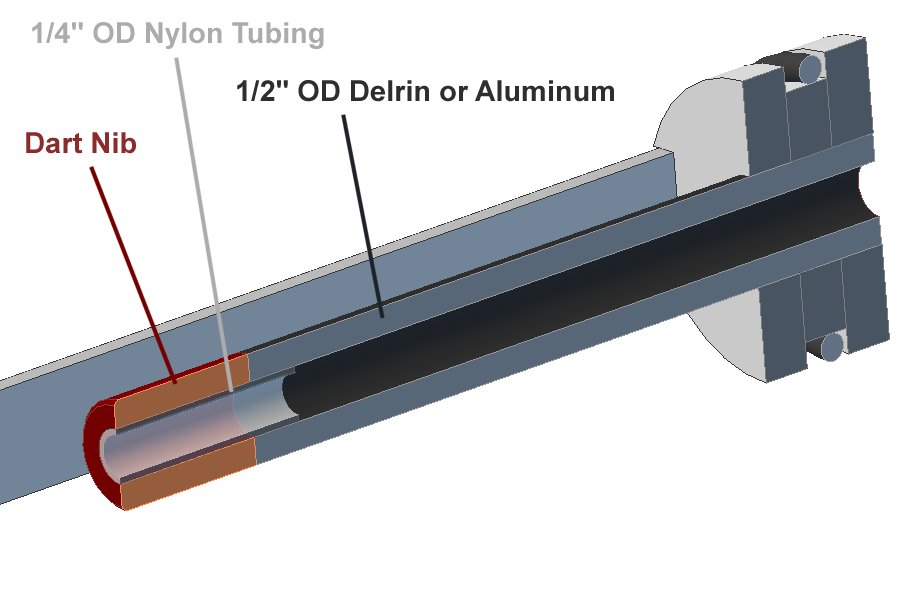

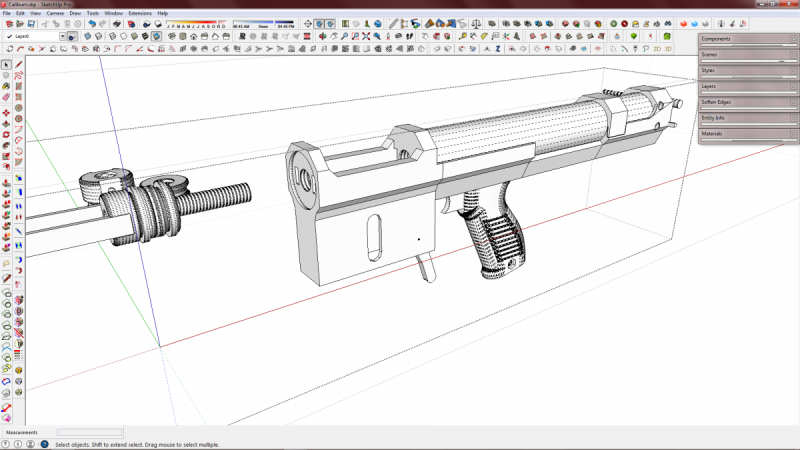

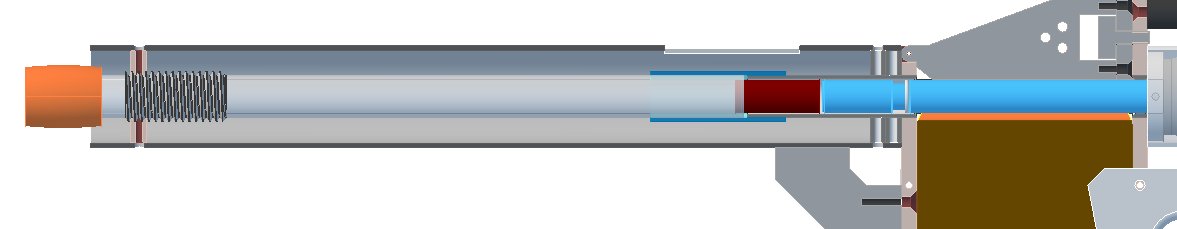

MACHINED VERSION

Write-Up: http://captainslug.com/caliburn.html

Partlist: http://captainslug.c...n_partslist.xls

Partslist

Templates: http://captainslug.c...n_templates.doc

STEP 214 CAD files: http://captainslug.c.../OGCaliburn.zip(436kb)

DXF Set: http://captainslug.c...aliburn_dxf.dxf

Assembly: http://captainslug.c...rn_assembly.pdf

Photo Gallery: http://imgur.com/a/3FVV3

Two of the parts in the write-up are optionally 3d-printed. If you don't have access to a printer those parts are available here.

https://www.shapeway...Y4NG/fgrip-ring

https://www.shapeway...RVQ4Q8DU/frame2

And if you want to add nameplates to your grip panels, here are the ones I'm using.

https://www.shapeway...49LW5/nameplate

Prototype

Special Thanks to skullface44, Meaker VI, RS09, jwasko, and RazgrizInferno. This design is directly inspired by the Rev-Shot, even if it doesn't really share any dimensions or parts.

Edited by CaptainSlug, 25 July 2019 - 12:48 PM.

Hardware List