Yes. You'd probably need to sand/smooth the printed part anyway unless you've got a high end printer. And PVC really is easy to chamfer - I usually use a regular pair of scissors. Beside that, you can seal with the manufactured PVC part easily, sealing with the printed ABS could be hit and miss, unless you design in an O-ring seal somewhere which just adds parts.

It's really easy to chamfer PVC, yes. I do this with my RSCBs and hoppers. However what I'm interested in avoiding with printing the chamfered part and making it stick into the tee joint is having to bore out the inside of the tee joint. How would you do that? I would use a boring bar on a lathe but it might be easier, if I'm making a few of these, to print that part. Well of course it's easier I guess. You're saying it might jam more. Quite possible. Those little rubber heads on darts are sticky.

Agree - for simplicity, 2 pieces of PVC would be easier and faster.

I'm unclear on what you guys mean by 2 pieces of PVC here. Could you clarify?

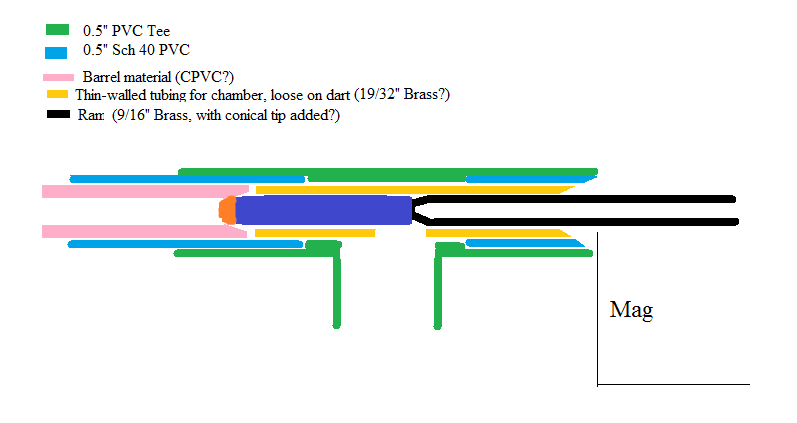

The design I have laid out has a seal between a cylindrical ram and a tubular chamber, and would probably have at least 0.25 up to0.5inches of overlap, like your average slide breech.

In any case I would think that the air cylinder would hold fast against the pressure emitted from the firing valve. You may be totally right that bounce is an issue, but personally I'd be more worried about premature retraction in Dskippy's blaster. In a springer you're right, bounce would be an issue and some sort of lockup would be needed.

Actually, for both Dskippy's semi-auto air blaster or for a springer: perhaps a simple catch could be designed. When the trigger is depressed, it notches into the ram to keep it closed. When the trigger is released, the ram may retract (by air spring, etc).

I agree, I really don't see how bounce could be an issue here. Premature retraction, however, has to be an issue to some degree. Whether or not it's enough to matter might be just a matter of testing. My original proposal is similar to what you're talking about jwasko. Which is to have the ram slide into the chamber a little bit. Hopefully it will reach the point of exiting the back of the chamber after the dart leaves the barrel. There's definitely an amount of overlap, length of barrel, and pressure of air that can make that work out. I might have to find a high speed camera I can borrow. ![]()

As for your simple catch idea, I don't see how this could work. You're suggesting that the ram can't retract until the trigger is released. This run counter to the mechanism I've proposed. Perhaps your design and mine are really not all that similar. I've never been completely explicit about my plan so I'll do that now. I had been considering two of them. One where a ram pushes the dart into the chamber and one where the barrel slides back over the dart. I have abandoned the latter based on this thread. Here's the former in detail.

---------

Design elements:

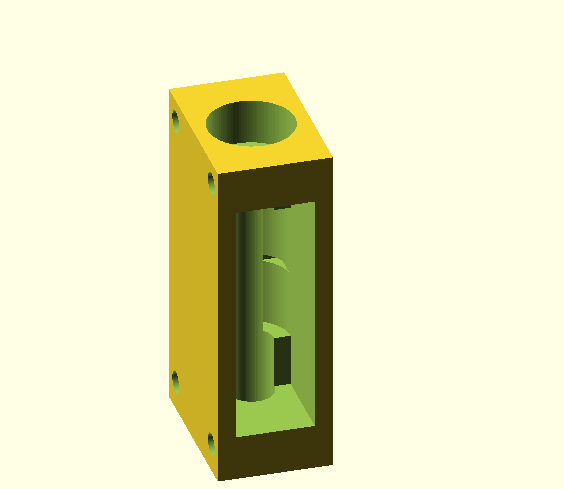

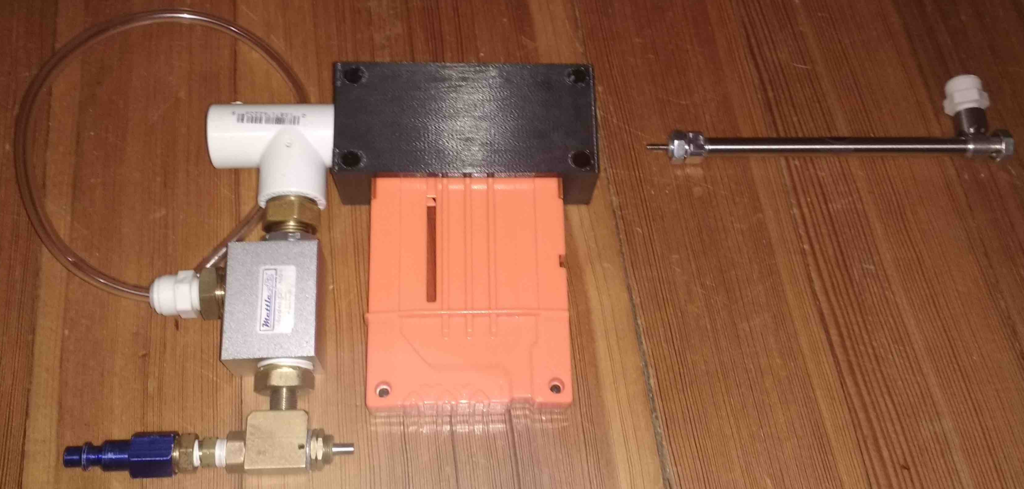

The mag well is a 3D printed part that mates nicely with N-Strike magazines and has a rounded ceiling that keeps the dart at the right height.

There's a hole in the back of the mag well where a ram can be extended to push a dart out the front of the mag well.

The ram has a tip on it that be pushed into the back of the barrel maybe a half inch to an inch and it seals the back of the barrel

The dart slides out the front of the mag well into the barrel.

The back of the barrel in cone shaped to make this as easy as possible.

The back part of the barrel has a hole in the bottom where air flows in from the blast chamber when triggered.

Operation:

State 1: The trigger is being held down. The ram is fully retracted. The barrel is empty. The magazine has a round pushed to the top.

State 2: The trigger has been let up. The DCV now allows air to flow from the tank to the blast chamber which includes filling the air cylinder. The ram now extends. A dart is pushed into the barrel. The ram seals the back of the barrel.

State 3: The trigger is pressed. The DCV seals off flow from the tank. The blast chamber is open to the barrel through the QEV now. Air pushes the dart out of the barrel. The ram also is retracting at this time. All of the air leaves the blast chamber causing the dart to leave the barrel. All of the air leaves the cylinder as well, causing the ram to retract all the way. Another dart pops up to the top of the magazine. The trigger is still depressed and we're now back to State 1.

--------------

So I think, unless I'm missing something, that this is totally incompatible with your idea to restrict the ram from leaving the barrel until the trigger is let up. What happens in the various stages of your design?