This is a gun a built a while ago. The full write-up is available on NerfRevolution, but here is a summary.

When I first saw Split's write-up for the original RTP, I was amazed by how simple the design was, and astounded by the ranges it was capable of. However, I, like many others, do not have the tools to machine polycarbonate. Since then it has been my goal to design and build a RTP-type blaster that uses entirely pre-fabricated PVC parts. With this blaster, I feel I have succeeded.

Before I continue, I would like to give credit to Split for the original RTP design, which can be found here:

http://nerfhaven.com...showtopic=19638The Write-Up

Parts

1 1/4" PVC

1" PVC (schedule 40)

1" PVC coupler

1x 1 1/4" metal washer

1x 1 1/4" rubber washer

1x 1 1/2" rubber washer

1" x 1/2" bushing

3/4" x 1/2" bushing

2x 1/2" CPVC endcaps

2x 1" #6 machine screws

3x #6 nuts (yes, I do mean THREE)

1x #6 wing nut

1x finishing washer

2x 1" metal washers

1/2" CPVC

1x +bow spring

1x roofing nail

1x clothes pin

1x angle iron (also called angle brace)

Wood (for handle

About 10x 1/2" #6 screws

Tools

Drill/screwgun

Hacksaw (a miter box is helpful, but not necessary)

Hot-glue gun

Some way to cut nails

How the gun works:

The sealing face is at the front of the plunger, but the catch notch is at the rear. You cock the gun by pushing the 1" PVC into the 1 1/4" PVC. the spring can't fit through the bushing at the front of the 1" PVC, but the plunger rod can. this compresses the spring, until the catch hits the clothespin trigger, locking it in place. when you pull the 1" pvc back, the spring remains compressed. Pulling the trigger releases the plunger rod, firing the dart.

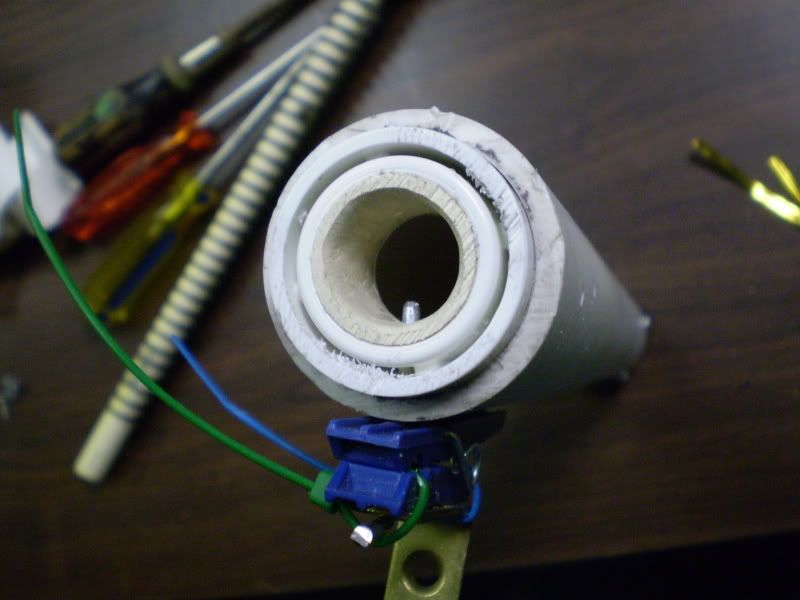

To make the sealing face, make a superlative plunger head, but DO NOT USE A SECOND METAL WASHER!!

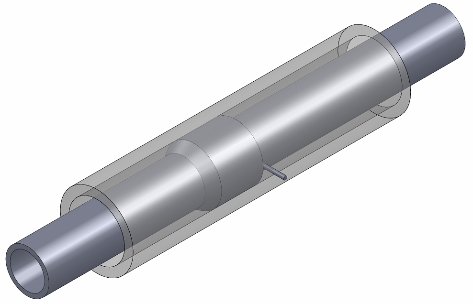

It should look like this:

You will now need to make the catch. The catch is effectively a superlative plunger head, but without the rubber washers, and with 2 hex nuts replacing the nylon spacer in the original design. This catch also uses 1" washers instead of 1 1/4".

Here is a picture of the completed catch:

The completed plunger rod should look like this:

Front half (ignore the handle):

Back half:

Whole thing:

Push the back of the plunger rod into the 1" pipe, making sure that the 3/4" bushing gets into the end of the 1" pipe. Make sure that the plunger doesn't fall out of the 1 1/4" pipe.

You are done!

In case you don't get how it works, the 1" PVC and 3/4" bushing function like the threaded rods and polycarb circles in splits version.

In detail:

The sealing face is at the front of the plunger, but the catch notch is at the rear. You cock the gun by pushing the 1" PVC into the 1 1/4" PVC. the spring can't fit through the bushing at the front of the 1" PVC, but the plunger rod can. this compresses the spring, until the catch hits the clothespin trigger, locking it in place. when you pull the 1" pvc back, the spring remains compressed. Pulling the trigger releases the plunger rod, firing the dart.

Disassembled pic:

Firing Video:

http://img191.images...i/dscn0431.mp4/I stabilized the thing like this

1. Loosen the screws holding the front bushing on.

2. Tie one end of the string to on of the front screws of the gun

(the paper is only to highlight the string)

3. Tighten that screw

4. Cut a small notch in the back of the gun.

5. Slip the string into the notch and tie it off back at the front bushing. Secure the string in the notch with hot glue, and tighten all screws.

The back of the gun should now look like this:

This method is pretty effective, and makes the whole thing easier to fire and use.

Final thoughts:

This Blaster is pretty much finished by now. Everything works, and ROF and ranges are impressive. The kite string is holding up well, and does not hinder priming or firing.

Ranges are a little less than my snapbow, probably ~90-100'

Qs? Cs? Fs?

This is reposted from a while ago, so it doesn't include the newer advances, like the ring catches. It is still a very fun blaster though. However, I must say I prefer my bows, because they are a lot easier to build.

some of these pictures got screwed up by the formatting. Click on them to view the whole thing.[/quote]