- NerfHaven

- → popatachi's Content

popatachi's Content

There have been 158 items by popatachi (Search limited from 12-December 96)

#201101 Longshot Replacement O-rings?

Posted by

popatachi

on 04 January 2009 - 06:16 PM

in

Modifications

Posted by

popatachi

on 04 January 2009 - 06:16 PM

in

Modifications

There's a part list on this thread from Caption Slug. Look in the Quoted Area and it will give you the dimensions of the washers that you will need.

Link

But the basic breakdown is:

Plunger head replacement

#10 1-1/4" OD steel washer

#10 1-1/2" neoprene washer

#10 1-1/4" OD steel washer

#8 steel washer

#203049 Painting Question

Posted by

popatachi

on 13 January 2009 - 09:47 AM

in

General Nerf

Posted by

popatachi

on 13 January 2009 - 09:47 AM

in

General Nerf

If you go this route, I would recommend that you first spray on a clear coat of gloss and then when that is dry, spray on the Dullcote.

Dullcote can be expensive ($3 - $5) and comes in a small spray can, but most commercial matte finishes are still semi-gloss or have a reflective sheen to them. I regularly use the two clear coat protection on miniatures that I have painted and it works really well.

#203176 Rear Loading Maverick

Posted by

popatachi

on 13 January 2009 - 10:10 PM

in

Modifications

Posted by

popatachi

on 13 January 2009 - 10:10 PM

in

Modifications

#211041 Bbb Help

Posted by

popatachi

on 10 February 2009 - 12:03 AM

in

Modifications

Posted by

popatachi

on 10 February 2009 - 12:03 AM

in

Modifications

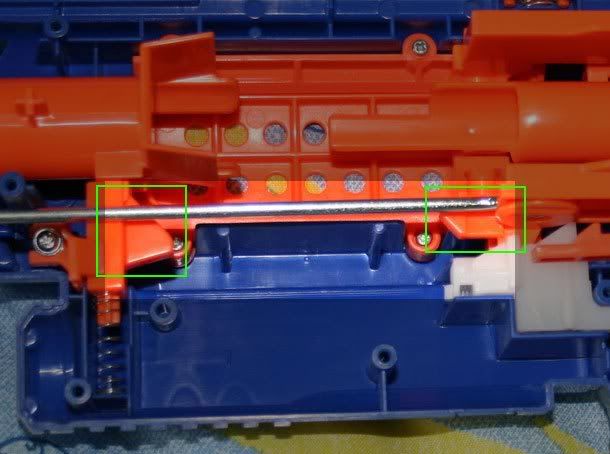

I was hoping that someone with a BBB could take a close up picture of their BBB when it is primed. Specifically, I am looking for a picture of the plunger area that will release the side locks once it has been fired.

I was adding hot glue to remove the dead space at the front of the plunger but may have added too much. And now I believe that the plunger is not going forward enough but I would like to know for certain. Here is the area in question:

The orange "nub" is part of the plunger and the gun has been fired. I would like to see where this piece is positioned on a working BBB and determine if that is the problem.

Any help is appreciated.

Thanks!

#211073 Bbb Help

Posted by

popatachi

on 10 February 2009 - 07:37 AM

in

Modifications

Posted by

popatachi

on 10 February 2009 - 07:37 AM

in

Modifications

Thanks again.

#211946 Azulsoli

Posted by

popatachi

on 13 February 2009 - 09:11 AM

in

Modifications

Posted by

popatachi

on 13 February 2009 - 09:11 AM

in

Modifications

#212294 Red Bbb

Posted by

popatachi

on 14 February 2009 - 08:05 PM

in

Modifications

Posted by

popatachi

on 14 February 2009 - 08:05 PM

in

Modifications

It's a great gun that's cheap, easily modified, and very durable. I would recommend getting it.

#250246 Raider Cs-35 - Dart Tooth

Posted by

popatachi

on 12 September 2009 - 07:17 PM

in

Modifications

Posted by

popatachi

on 12 September 2009 - 07:17 PM

in

Modifications

This is because the dart tooth starts to move down when it is in contact with the bolt sled. There is a small arm at the bottom that pushes the dart tooth down. If you trim these two pieces down, they won't make contact until the priming sequence is near the end and pushes the dart further into the bolt rather than having it half in the bolt, half in the chamber.

Hopefully this picture will help.

This is the dart tooth and the arm on the bolt sled.

For reference, here is a picture from the raider over haul thread (thanks SPV999).

One thing to note, be careful how much you trim off the dart tooth. Trimming too much or at too steep an angle won't allow the top of the dart tooth to clear the bottom of the chamber tube. In my modification, the top is just about flush with the chamber. So make sure to try and keep the same angles.

Enjoy!

#250254 Raider Cs-35 - Dart Tooth

Posted by

popatachi

on 12 September 2009 - 08:36 PM

in

Modifications

Posted by

popatachi

on 12 September 2009 - 08:36 PM

in

Modifications

Here's a quick video I took. I primed the raider up until the last moment before it locks. And you'll see that I push on the dart showing that I'll all the way back in the bolt. Sorry I didn't take a video or pics pre mod.

#250303 Raider Cs-35 - Dart Tooth

Posted by

popatachi

on 13 September 2009 - 10:11 AM

in

Modifications

Posted by

popatachi

on 13 September 2009 - 10:11 AM

in

Modifications

@Lt. Stefan: Yeah, it's not going to give you a significant boost, but every little bit helps.

#251260 Modification and Paintjob Pictures

Posted by

popatachi

on 22 September 2009 - 09:49 AM

in

Modifications

Posted by

popatachi

on 22 September 2009 - 09:49 AM

in

Modifications

Bolt

Barrel

Internals

#254146 Breech Lock N' Load

Posted by

popatachi

on 20 October 2009 - 09:47 PM

in

Modifications

Posted by

popatachi

on 20 October 2009 - 09:47 PM

in

Modifications

Thanks to Cxwq and Forsaken_angel24 for the knowledge and inspiration.

Materials:Lock 'n Load

PVC: 1/2"

Brass: 17/32" & 19/16"

Paperclip

1/16" drill bit

Electrical Tape

Key Ring

Tools:Dremel

Glue: Zap-a-Gap

Files

Step 1: Remove the screws and open up the shell

Open the Lock n' Load and put away the green top shell and the bottom dart holder. These aren't needed. This is also a good time to trim and cut away any excess from the shell as desired. I trimmed the sides and back of the shell.

Step 2: Cut the barrel

Take the orange barrel and cut 1/4" from the plunger tube. Do not throw the barrel away just yet.

Step 3: Create the breech in the barrel

Take your 9/16" brass and cut a 4" length

Take your 17/32" brass and cut a 3 5/8" length (this could be a bit shorter as well)

Take your PVC and cut a 3 5/8" length

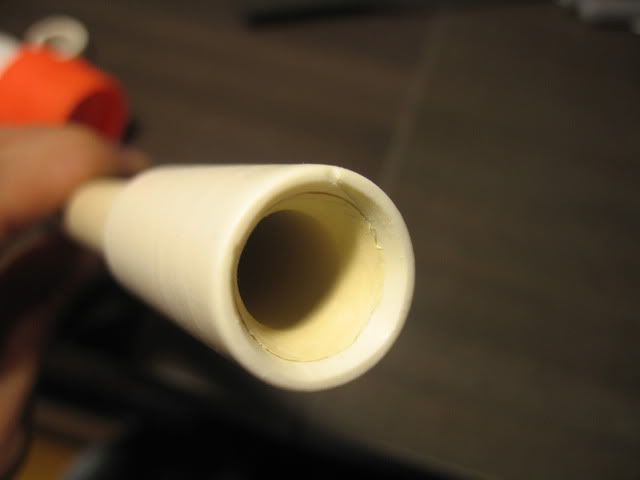

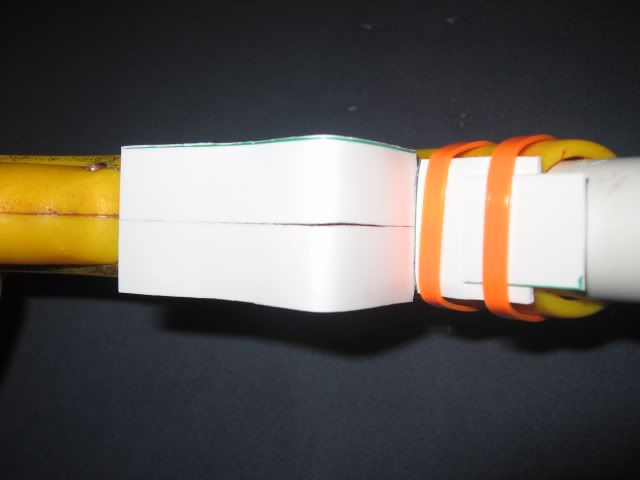

Start with the PVC length and measure your dart's (my darts are about 2") length 1/8" away from one end and draw the opening for the breech.

Cut this away and smooth the edges.

Insert the 9/16" brass into the PVC making sure that the two ends are flush at the opposite ends of the breech (away from the opening) and mark the opening on the brass using the PVC as your guide.

Cut this away and smooth the edges.

Use two layers of electrical tape around the 9/16" brass and insert the brass into the PVC. Dry fit the pieces together and once set, use glue on both ends of the breech to secure and make the breech air tight (so that air will only go through the brass and not leak between the brass and the PVC)

Wrap a single layer of electrical tape around the exposed 9/16" brass to give a better fit into the orange barrel.

Step 4: Create the breech opening in the shell

Insert the new barrel into the orange barrel. Make sure to line the opening in the plunger at the bottom and decide which side you want the breech to be on and twist the two pieces until it is to your liking.

And now the scary part.

Take a small drill and make a pilot hole into the side of the shell trying to get the center of breech. Hopefully you will see the brass directly below. Take a wider drill and open up the hole so that you can now see where the breech is located.

Remove the shell and slowly cut away the shell to expose the entire breech. Measure as many times as you need and go as slow as possible. Remember to take into account any filing or sanding that you might do for the edges so don't try to make your cuts final, let the file make the final edge.

The opening in the shell is about the width of a 9 volt battery as a point of reference.

Step 5: Fit the barrel into the shell

Use your dremel to widen the opening of the blaster to be able to fit the PVC. Work slowly in a full circular motion. The difference isn't too big.

In order to keep the barrel and plunger from spinning, I files two grooves into the PVC. One at the top in front and another at the bottom in the back.

Take the original orange barrel and cut the corresponding posts and trim down any excess flash. And dry fit these in place against the PVC. Make sure to not trim too much away. Once you have the fit, glue these posts to the PVC.

Alternatively, you could just hot glue the PVC against one of the shells to keep it from moving.

To keep darts from falling into the plunger tube, drill through the orange barrel and through the brass. I used a 1/16" drill bit.

Open your paperclip and insert a straight length through the openings and clip off a length enough so that the wire overhangs the barrel.

Re-insert the paperclip and glue this into place. When the glue is dry, use your dremel to sand the ends of the clip and push down to help fill in the gap and make it flush to the barrel. Add glue to seal it up.

Step 6: Create breech tab

Put the barrel into the shells and close it up.

Insert the 17/32" brass length into the breech and close the opening.

I used the PVC left over from the breech opening and cut four small pieces roughly the same size. These were filed and glued on top of each other. File these into a tab and determine how you want your tab to look and where to position it.

Once you are satisfied with the tab, push the 17/32" length a little past the opening of the breech. This will make sure it is properly sealed. Do not push the length all the way to the back of the barrel because when you open the breech, the opening will smaller due to that plus the tab.

Slide the 17/32" into the middle position, mark where your tab will be and glue it to the brass being sure to not use too much glue.

Step 7: Plunger Rod and Key Ring

Make sure to clean the plunger tube and rod. Wrap two layers of electrical tape around the plunger head for a better seal. If you have an extra or different spring, add that in place. I didn't have a replacement spring for this write up.

If you have a key ring, attach that to the end of the plunger rod.

Assemble all the parts.

Step 8: Finished

All done! Ranges are about 40 ft flat and very accurate.

UPDATE:

Completed my second LnL with a CPVC breech. Both blasters have chainblazer replacement springs and some shell work. Also, a plunger handle has been added instead of the keyring.

#254166 Breech Lock N' Load

Posted by

popatachi

on 20 October 2009 - 11:24 PM

in

Modifications

Posted by

popatachi

on 20 October 2009 - 11:24 PM

in

Modifications

@heavencloud92: You could add tightening rings in the 17/32" as xbox180 stated. I don't think it would interfere with the system at all.

#254186 Breech Lock N' Load

Posted by

popatachi

on 21 October 2009 - 08:00 AM

in

Modifications

Posted by

popatachi

on 21 October 2009 - 08:00 AM

in

Modifications

#254268 Breech Lock N' Load

Posted by

popatachi

on 21 October 2009 - 08:28 PM

in

Modifications

Posted by

popatachi

on 21 October 2009 - 08:28 PM

in

Modifications

As for the barrel length, I followed the instructions from Cxwq and FA24's individual write ups that use a 4" barrel. I wanted to keep the length at 4" and so I created the tab.

@everyone else: Thanks for the compliments! This was a lot of fun!

#254298 Breech Lock N' Load

Posted by

popatachi

on 22 October 2009 - 09:13 AM

in

Modifications

Posted by

popatachi

on 22 October 2009 - 09:13 AM

in

Modifications

And where my effort should go is entirely up to me thanks.

#254894 Rebarrelling Buzzbee Belt Blaster Shells

Posted by

popatachi

on 29 October 2009 - 08:05 PM

in

Modifications

Posted by

popatachi

on 29 October 2009 - 08:05 PM

in

Modifications

#255359 Modification and Paintjob Pictures

Posted by

popatachi

on 05 November 2009 - 12:41 AM

in

Modifications

Posted by

popatachi

on 05 November 2009 - 12:41 AM

in

Modifications

7" CPVC barrel

Reduced dead space:

PVC elbow is nested in the head of the blaster. The plunger goes about 1/4" into the PVC elbow.

The elbow and tee tubes were cut in half.

Drilled two holes into the tee and covered with plastic to see if there's a dart loaded into the barrel.

PETG breech.

Holds 5 2" stefans or 6 1.5" stefans.

#255372 Rscb Bbb

Posted by

popatachi

on 05 November 2009 - 11:11 AM

in

Modifications

Posted by

popatachi

on 05 November 2009 - 11:11 AM

in

Modifications

For this modification I wanted to try and reduce as much dead space as possible and still get an easy to load RSCB.

Materials:Big Bad Bow

1/2" PVC elbow

1/2" PVC Tee

1/2" PVC tube (6 3/4" for darts, 2" to nest barrel, 1" for connection)

CPVC tube (6" for barrel, 1/2" for connection)

CPVC end cap

PETG (for breech or another material)

PVC clip

Extria screws

Tools:Dremel

Zap-a-Gap

Plumber's Goop

Files

Electrical Tape

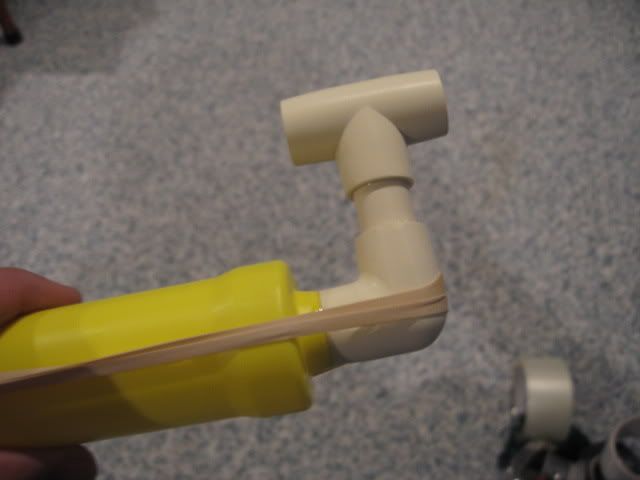

Step 1. Modify the front cap, ring, and elbow

Most modifications start with attaching a coupler to the front cap and nested CPVC into the barrel and filling the dead space with hot glue. I opted to try a different method of attaching the PVC elbow directly into the front cap. This will reduce the dead space and not require a lot of hot glue in the process.

To do this, you will need to cut off the exposed area of the front cap and widen the hole in the cap until the PVC elbow can slide through. Try to get a good fit and not widen the hole too much.

The white ring that was part of the air restrictor was used to help support the PVC elbow. The hole had to be widened just a bit to be able to accept the elbow. Once the PVC elbow can go through the ring, glue the ring to the front cap. Be sure that the ridge is facing the front to the cap.

I used goop in the front of the ring and Zap-a-Gap at the back to make sure no air can get through.

As for the PVC elbow, I had to file down the inner area to allow the elbow to reach a little further back into the cap.

In the above photo, notice on the left side of the PCV wall with trimmed straight. I did this to both the elbow and the tee just so that it matches.

Step 2. Modify the BBB Shell

There are two areas that need attention. The bottom of the barrel opening and the front handle.

I removed the bottom lip of the barrel opening to allow the PVC elbow to get even further down into the plunger tube so it can be as close to the plunger head as possible.

The front handle was removed so that the PVC that will hold the darts can be added in this area. Sand the area flat. The front handle will not be used and can be discarded or saved for future modifications. Optionally, you can move the location to the RSCB barrel to above the blaster if you want to keep the bottom for an integration.

Step 3. Create the RSCB

To remove more dead space, take the PVC elbow and cut half of the tube that will connect to the PVC tee and do the same to the middle tube on the PVC tee. Make sure to get these as straight as possible.

Take your 1" connection PVC tube and dry fit these pieces together. When you are satisfied with the fit, use goop or Zap-a-Gap to secure the assembly.

You have different options for your barrel, but I opted to use a 7" length of CPVC nested in a 2" length of PVC. The important part of the barrel is to cone out the end that will be put into the PVC tee. I used a dremel to cone out the CPVC enough to allow a dart to fit in about 1/4". Once you have your barrel, dry fit this into the PVC tee.

Now take the 7" length of PVC and attach that to the other end of the PVC tee. Take the CPVC end cap and cut it in half. You may need to dremel out the inside if there is a ridge at the back. Take the CPVC connection and glue it into the end cap. Attach this cap to the PVC dart barrel. It should have the same diameter as the PVC.

I opted to create a breech so that I wouldn't have to pull the barrel off to reload. Cut a 3" hole into the tube, nest PETG with electrical tape wrapped around the ends and glue on a tab.

In order to quickly see if there's a dart in the barrel, drill two holes through the PVC tee and cover these with plastic and secure with glue.

Take your RSCB and dry fit this into the BBB shell.

Step 4. Glue

You don't need to glue the barrel and/or the dart holder if you want to be able to remove either of these pieces.

Now take the assembly and glue the elbow to the white ring in the BBB's front cap.

Step 5. Seal it up

I added electrical tape between the front cap and plunger to keep air from escaping. I also added some glue between the elbow and front cap at the opening for a little more stability.

Attach the PVC at the end of the dart barrel to stabilize the PVC. I also used some scrap plastic from a VHS box to help secure the front of the shell as well.

Step 6. All Done!

At this point the mod is complete.

I was going to add a front grip with a 2" PVC but the connection point with the shell didn't have enough room for screws. So I'm looking into some rubber door stoppers to add to the sides of the shell to be able to grip the blaster as I'm priming it. In the meantime, you can hold the back of the front blaster to prime.

Ranges:

With a shorter barrel (6") and better plunger seal (flared out the plunger head) I am averaging 75ft with single BB stefans.

#255378 Rscb Bbb

Posted by

popatachi

on 05 November 2009 - 11:53 AM

in

Modifications

Posted by

popatachi

on 05 November 2009 - 11:53 AM

in

Modifications

@k9turrent: I totally did! I used a combination of yours and Mr. BadWrench's write ups on RSCBs to help me work through this thing. Thanks!

#255387 Rscb Bbb

Posted by

popatachi

on 05 November 2009 - 01:07 PM

in

Modifications

Posted by

popatachi

on 05 November 2009 - 01:07 PM

in

Modifications

@berserker: When I first tried this out, I kept tipping the blaster up to see the barrel, but I am getting use to the idea that I don't need to see the barrel to aim. As long as the RSCB is straight, it's just a slight adjustment when aiming.

#256449 Looking For The Name Of This Blaster

Posted by

popatachi

on 16 November 2009 - 09:08 AM

in

General Nerf

Posted by

popatachi

on 16 November 2009 - 09:08 AM

in

General Nerf

It's like a mini shotgun. There's a pink priming handle, light at the top front, and I think it shoots megas.

On the shell:

1993 TYCO PLAYTIME, INC.

MADE IN CHINA

The only thing I could find was that Tyco acquired Playtime in Jan of 1991. Also, Playtime in Dec of 1991 acquired Helm Toys, but there isn't much on that company to search through.

Playtime also made some water toy guns:

(excerpt taken from here: link)

The first sample is called "The Ripper," model number 3020. This water gun is approximately twenty (20) inches long. The water gun is predominantly bright green. There are orange paw designs overlaying the green. The trigger, side hand grips, water magazine, and pump action portions are purple. "Made in China" is imprinted on the gun just above the magazine opening. The markings on this gun comply with the regulations.

The second sample is called "AK Centerfire," model ASST. 3021. This water gun is shaped like a machine gun and is approximately twelve inches long and seven inches high. The plastic magazine cartridges are black and there is a black ring where the barrel extends from the main body of the toy gun. The predominant color of this water gun is red with flashes of blue. We conclude that the predominant red color is not bright; therefore, this toy gun fails to comply with the regulations.

The last sample is the "Water Hawk," model ASST 3022. The size of this water gun is similar to the AK Centerfire above. The magazine cartridge is bright green. The predominant color is blue with red diamond shaped designs on the sides. We conclude that the predominant blue color is not sufficiently bright and fails to comply.

Here are some internal pictures:

Overview:

Close up of catch system: (I couldn't find any compression springs in the catch system. It was just the big torsion spring underneath the catch)

Plungers: (these are completely closed on both ends, but seems easy enough to pop off. They are 4 3/4" in length and just a hair under 1" in diameter)

Inside the Plunger: (The plunger cap is the orange disk, clear plunger head, black disk. This assembly was screwed into the plunger rod. I was able to remove the front by scoring joint with a knife and wiggle it until it pops off)

Exterior:

There are two sizes of screws all around the blaster. There are two screws in the side of the orange cap that I missed as well. The pink priming handle is attached to the rod by two pins.

Front without light setup: (There is about 1 15/16" from the plunger to the front of the shell)

Front light setup: (requires two AA batteries)

Let me know if you need any more pictures.

#256456 Looking For The Name Of This Blaster

Posted by

popatachi

on 16 November 2009 - 10:47 AM

in

General Nerf

Posted by

popatachi

on 16 November 2009 - 10:47 AM

in

General Nerf

#256517 Looking For The Name Of This Blaster

Posted by

popatachi

on 16 November 2009 - 09:13 PM

in

General Nerf

Posted by

popatachi

on 16 November 2009 - 09:13 PM

in

General Nerf

#256539 Looking For The Name Of This Blaster

Posted by

popatachi

on 16 November 2009 - 11:44 PM

in

General Nerf

Posted by

popatachi

on 16 November 2009 - 11:44 PM

in

General Nerf

#256564 Looking For The Name Of This Blaster

Posted by

popatachi

on 17 November 2009 - 08:12 AM

in

General Nerf

Posted by

popatachi

on 17 November 2009 - 08:12 AM

in

General Nerf

I found that PVC fits into the plunger tube (but the plunger rod ends right at the lip of the tube) so I figured the easiest method would be to cut the prong (?) from the plunger cap and glue CPVC to that. But I wasn't sure how to stabilize the CPVC.

#256576 Looking For The Name Of This Blaster

Posted by

popatachi

on 17 November 2009 - 12:43 PM

in

General Nerf

Posted by

popatachi

on 17 November 2009 - 12:43 PM

in

General Nerf

One of the funniest parts on the blaster is the light switch.

"0 Off / 1 On"

I guess it was written that way just in case machines pick it up and need to turn on the light! (Ahhh computer humor)

Also, the person I got this from might have another one. If I am able to get a second, I'll make it available to buy here. I'll know in a couple of days.

#256718 Looking For The Name Of This Blaster

Posted by

popatachi

on 18 November 2009 - 08:49 PM

in

General Nerf

Posted by

popatachi

on 18 November 2009 - 08:49 PM

in

General Nerf

I was able to get the second blaster! I will be putting this up in an auction but since I'm going to be busy until after Thanksgiving, it won't go up here until then to give everyone a chance who might want this.

Looking it over, there aren't any cracks in the shell. It primes and fires, but the pink handle sticks a little when pushed back (could just need a little cleaning). There is scotch tape on the pink handle, but doesn't look to be anything broken underneath. I didn't check the working condition of the light and have not opened it up.

Let me know if you have any other questions.

#257707 Mav Help

Posted by

popatachi

on 01 December 2009 - 03:58 PM

in

Modifications

Posted by

popatachi

on 01 December 2009 - 03:58 PM

in

Modifications

The back barrels of the turret do not meet with the front barrels so you are most likely losing air between that gap. To test, plug the front with your finger and blow into the back. If air is escaping, that's your problem.

To fix the gap, you can use the AR caps and drill out the peg, or use craft foam to cut to the shape of the turret with holes that will allow air through each barrel, or add a new barrel that will be air tight from back to front.

When I used CPVC, the turret became too heavy so I switched to PETG but you will need to remove some of the front barrels to get it to fit.

Hope that helps.

#258231 Modification and Paintjob Pictures

Posted by

popatachi

on 06 December 2009 - 11:19 PM

in

Modifications

Posted by

popatachi

on 06 December 2009 - 11:19 PM

in

Modifications

I don't have ranges as it was snowing and it's night time.

And here's a tip. Need a half coupler? If you don't want to spend time cutting up a full coupler, get an end cap and drill a hole through it.

Make sure to make the hole smaller than the original hole so that the pipe doesn't go through. You can see in the picture below the ridge in the cap.

#259015 Rscb Bow And Arrow

Posted by

popatachi

on 14 December 2009 - 09:53 PM

in

Modifications

Posted by

popatachi

on 14 December 2009 - 09:53 PM

in

Modifications

Credit to Fome for the original writeup.

Video Review

Materials:Bow and Arrow

CPVC coupler

CPVC tee

1 1/2" length of CPVC

3/4" length of CPVC

9" length of CPVC

1 CPVC end cap

10" length of 5/8 PETG

2" length 1/2 PETG

1 Screw

1 Bungee cord

2 ScrewsTools:Hack saw

Dremel

Files

Sand paper

Glue (Goop and hot)Step 1: Disassemble the blaster

Remove the eight screws and open up the blaster. Take out the plunger and plunger rod and inspect everything for cracks, chips or any signs of wear.

Step 2: Modify the plunger head

Different models of the Bow and Arrow have a different plunger head. Here is mine. You have to remove two white plastic pins in order to remove the plunger head.

Flare out the plunger and add some hot glue to help increase the seal.

Saw off the small white cap at the top and glue one some foam to help pad the plunger and fill the space with hot glue.

Connect the plunger assembly. My Bow and Arrow only had one white cap, so I opted to use a screw to hold the assembly together.

Step 3: Modify the blaster shell

In order to minimize as much dead space as possible (because there will be some already with the height) I opted to attach the RSCB as close to the plunger tube as possible. This meant cutting the shell to allow the CPVC to be closer.

Cut off the top front area of the blaster and widen the hole to the plunger tube. Use the inner walls of the blaster as your guide. Sand smooth and round the edges. Test fit your CPVC elbow to make sure it will fit properly when the blaster is closed. I also sanded the sides of the CPVC elbow to help with the fit.

Step 4: Create the RSCB assembly

Close the blaster and insert the CPVC elbow into the front opening. Take your 1 1/2" CPVC length and insert that into the elbow and attach the tee to the top. Make sure that this assembly is straight and is lined up with the hole in the top handle. Take the 3/4" length of CPVC and add that to the other end of the elbow.

When you are satisfied with the fit, put it aside.

Step 5: Cut down the existing barrel

Take the plunger tube and cut off the plunger tube that accepts the arrows. This is about 1/4" away from the plunger tube, but it may vary depending on your CPVC. I ended up cutting about 3/4" and then filed the tube down dry fitting the elbow and plunger tube into the shell to make sure of the fit.

To help stabilize the RSCB assembly, add hot glue in the shell and a couple of tabs to the elbow to keep the assembly secure.

(The tabs are partially hidden by the electrical tape.

Step 6: Dry fit, glue, re-assemble

Put everything minus the plunger rod together and turn it around and around. Make sure that everything is how you want it to look.

Now take out your glue and glue the RSCB assembly, and when that is dry, glue the assembly to the plunger tube. Because the plunger tube is a soft plastic, give it a generous amount of time to dry and use a lot of goop and then wrap in electrical tape.

Step 7: Add barrel and dart chamber

For the dart chamber I was able to find 5/8" outer diameter PETG. This is the same diameter as CPVC and it fits OMC's PETG very tight. Add this to the CPVC tee, add a cap, and make a breech in the back to be able to load darts. Once dry, glue this to the back of the tee. This particular dart chamber can hold seven 1.5" stefans.

For the barrel, make sure to cone out the back of the barrel so that darts fit about 1/4" into the barrel. Attach and glue this to the front of the tee.

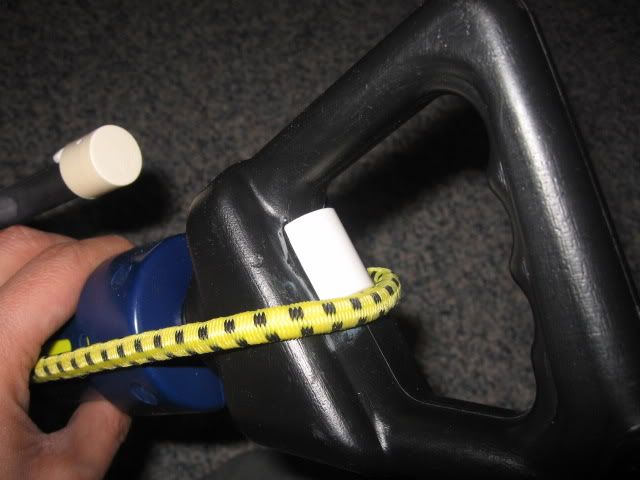

Step 8: Add bungee cord

In order to add a bungee cord, some reinforcements are needed. Take the 2 screws and cut them down to fit into the slots seen in the pictures below. Cut away the middle slot, drop in the screw and add hot glue around the slot and below that one as well.

Get your bungee cord and check the fit. I had to remove the rubber from the hook in order to get the hook to sit flush with the blaster shell.

On the handle, cut some spare piece of PVC and glue it to the top of the inside of the handle. This will help to keep the bungee cord straight as you draw back the plunger.

Step 9: All done!

The picture doesn't have the pink arms, but those will get attached with no modifications.

I don't have ranges yet. I'll post them when I get to it.

I would definitely recommend reinforcing the bottom handle as it can and will break over time. I haven't done it yet, but here's link to a thread the fixes it post-break. Bottom handle fix

#259036 Rscb Bow And Arrow

Posted by

popatachi

on 15 December 2009 - 12:26 AM

in

Modifications

Posted by

popatachi

on 15 December 2009 - 12:26 AM

in

Modifications

@Blue: thanks! This thing is a lot of fun, I can't wait to try it out doors.

#259161 Rscb Bow And Arrow

Posted by

popatachi

on 16 December 2009 - 01:11 PM

in

Modifications

Posted by

popatachi

on 16 December 2009 - 01:11 PM

in

Modifications

I had also thought about trying to find a replacement plunger tube out of PVC? But didn't invest too much time into looking for one.

Overall, it is a fun blaster.

#259286 Modification and Paintjob Pictures

Posted by

popatachi

on 18 December 2009 - 12:59 AM

in

Modifications

Posted by

popatachi

on 18 December 2009 - 12:59 AM

in

Modifications

#259543 Modification and Paintjob Pictures

Posted by

popatachi

on 22 December 2009 - 01:15 AM

in

Modifications

Posted by

popatachi

on 22 December 2009 - 01:15 AM

in

Modifications

#259619 Nite Finder - Closing The Gap On A Minimized Shell

Posted by

popatachi

on 23 December 2009 - 12:45 AM

in

Modifications

Posted by

popatachi

on 23 December 2009 - 12:45 AM

in

Modifications

MaterialsNite finder

1 mm thick plastic styrene (Brands include Plastistruct or Evergreen and can be found in most hobby shops)

- The styrene I purchased came in a pack of two 1mm sheets that are 12" x 6" in size for about $5. Here is a link to www.towerhobbies.com that sells it and so you can see the product.

ToolsSharp Blade

Glue (Zap-A-Gap)

Zip ties (a lot of them)

Files

Sandpaper

Dremel

Step 1: Minimize your blaster shell.

I opted to remove the top rail and front light. Make sure to sand the down the areas to be smooth.

Step 2: Prepare the styrene.

Cutting styrene is really easy. Just score the cut line with a sharp knife a couple times and you can snap it off by bending the styrene at the cut mark at the edge of a table. For each of these areas, I cut wide of the measured mark and sanded down to the desired point. This was done so I didn't undercut any areas and have to trash any pieces. Be sure to measure as your dimensions may be different.

Top rail: 13/16" x 4 3/16" (I cut about at most about 1/4" wider than the finished dimensions). This was then cut in half and marked to know which ends connected.

Front: This was done in two sections. Underneath the barrel and around the trigger guard.

- Underneath: 15/16" x 14/16" (because this was not a straight section I left it complete and cut it once glued to make sure the middle area didn't warp)

- Guard: 1 2/16" x 2 1/2" (also complete and cut after glued)

Once you have your styrene cut, lightly sand the area that will be glued to the blaster shell. This will help the styrene adhere better.

Step 3: Glue!

Remove the internals of your nite finder and close the shell. Starting at the top, place a small amount of glue on the top shell making sure to not get too much around the join of the shell. Take one side of your styrene and line up the inside of it with the join in the shell on both ends and press firmly. Quickly take the other side, making sure your match marks meet, line it up, press it down firmly.

Let this sit for a couple hours.

NOTE: I tried using a heat gun to get the bend right, but the plastic warped too much and I wasn't able to get it uniform.

Get your zip ties ready.

I started with the trigger guard since that was going to be the most difficult. Place a small amount of glue along the front of the guard and a little around the corner. Quickly place down the styrene press firmly. In a couple minutes, slowly bend the styrene around the guard making sure that the front area doesn't move during the bending process. Once you have the styrene bent relatively well, put some glue along the bottom, again be careful not to get too much by the join, and press down firmly.

Now grab your zip ties and start wrapping them around the guard. This will hold down the styrene to the shape of the guard. Make sure to get the zip ties tight and to pay special attention to the curves. You can use spare styrene underneath the zip ties to help keep the styrene straight and tight against the shell.

Let this dry overnight.

Once the guard is dry, remove the zip ties and inspect the styrene to make sure it fits correctly. Using your knife and a bendable ruler, lightly score a join down the entire length of the styrene. Go light and easy making multiple light passes rather than one heavy pass. In a couple minutes, the styrene will separate.

Now follow the same process for the area underneath the barrel.

Once all the areas have been covered, open the blaster and add glue to the interior of the shell for further strengthening the bond of the styrene to the shell.

Step 4: Sanding

Now that you have the shell covered up, use your dremel/files/sand paper to reduce the styrene to fit the shell any way you see fit.

Step 5: All done!

This process can work for any blaster shell and just takes time, patience and an abundance of zip ties.

Extended Draw

For the plunger, I glued on a PVC end cap and drilled through the cap to create a coupler and added a dart stop wire made from a paper clip. I then widened the hole in the front of the blaster to allow the PVC to fit.

To extend the draw, find the point where the plunger rod almost hits the outside of the shell and make a mark through the outside of the shell onto the plunger tube. These marks can be used to add CPVC strips to the plunger tube to secure it into the shell. I also added some supports for a post but that wasn't completely necessary.

In order for the front of the shell to close properly, I found a 1" post at Ace Hardware for the guard and cut one of the existing posts from the Nite Finder's front area for the top of the shell. The second picture doesn't show the top post.

If you have any questions, reply and I'll try to answer them as best I can.

Ranges: Averaged 75ft with a single BB stefans.

#259621 Nite Finder - Closing The Gap On A Minimized Shell

Posted by

popatachi

on 23 December 2009 - 12:54 AM

in

Modifications

Posted by

popatachi

on 23 December 2009 - 12:54 AM

in

Modifications

#259670 Nite Finder - Closing The Gap On A Minimized Shell

Posted by

popatachi

on 23 December 2009 - 08:11 PM

in

Modifications

Posted by

popatachi

on 23 December 2009 - 08:11 PM

in

Modifications

Some light scoring would definitely work with really sharp or narrow curves and corners though. Thanks for the extra thoughts, that is useful to keep in mind.

#259919 Photobucket Issues

Posted by

popatachi

on 27 December 2009 - 09:28 PM

in

General Nerf

Posted by

popatachi

on 27 December 2009 - 09:28 PM

in

General Nerf

#259924 Modification and Paintjob Pictures

Posted by

popatachi

on 27 December 2009 - 10:09 PM

in

Modifications

Posted by

popatachi

on 27 December 2009 - 10:09 PM

in

Modifications

I'm thinking of permanently adding it to my nitefinder.

- NerfHaven

- → popatachi's Content

- Terms of Service and Privacy Policy

- Code of Conduct ·