- NerfHaven

- → Viewing Profile: Posts: 3DBBQ

3DBBQ

Member Since 30 Jul 2003Offline Last Active Jul 10 2020 01:20 PM

Community Stats

- Group Members

- Active Posts 214

- Profile Views 74,542

- Member Title Member

- Age 41 years old

- Birthday June 18, 1984

User Tools

Latest Visitors

Posts I've Made

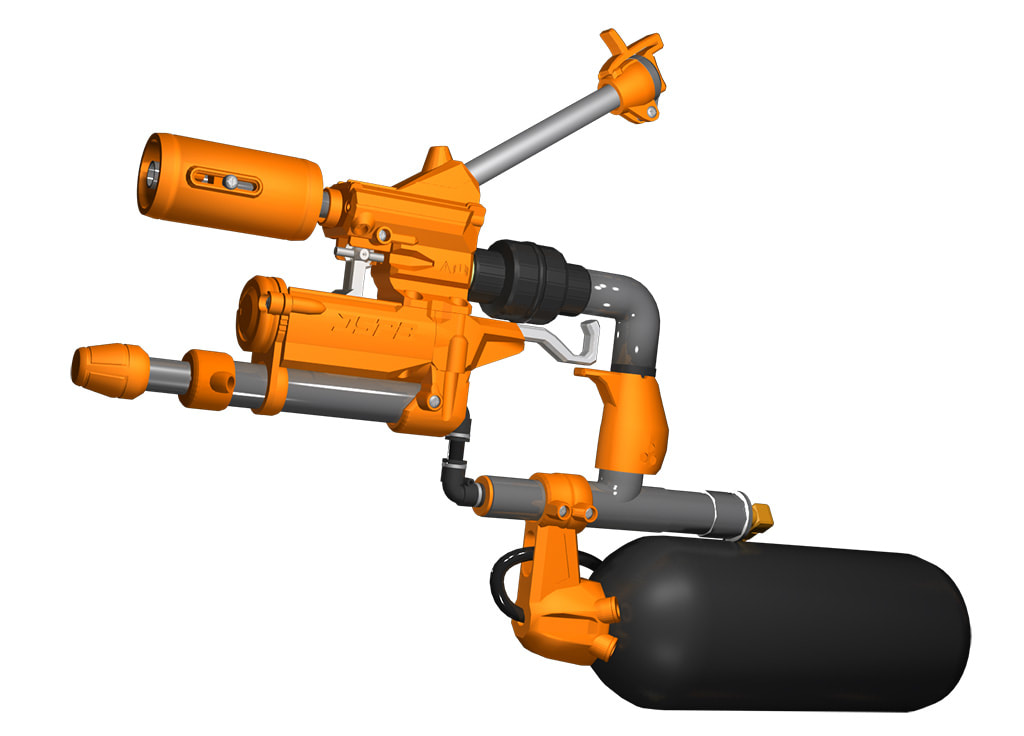

In Topic: ESPER - Elastic Spring Plunger Experiment (with a) Really cool name

18 November 2018 - 10:30 PM

In Topic: Mk18 Assault Pistol

18 November 2018 - 10:20 PM

Will Mk18 Assault Pistol publish a DIY KITS?

I am interested in this.

In Topic: JSPB-Urban OPS

18 November 2018 - 10:50 AM

In Topic: JSPB B&B mini-hopper

04 October 2017 - 10:09 PM

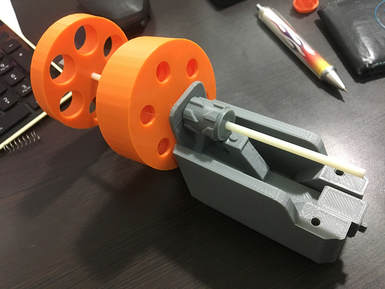

I'm curious about your turret development.

I intend to use rubber band as a rotating power, pre-winding idea,this will be easier than pressing the trigger.

There is one aspect that i'm especially interested in - the flip top hopper feed cap. Is that one you might consider releasing the files for?

It has been released for some time and can be found in the free models

In Topic: JSPB B&B mini-hopper

01 October 2017 - 08:12 AM

Thanks to everyone who contributed ideas.

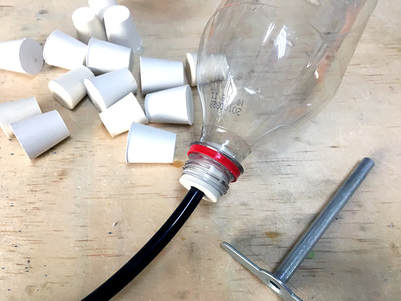

I adopted soda bottle for designing. It is very light and works just fine.

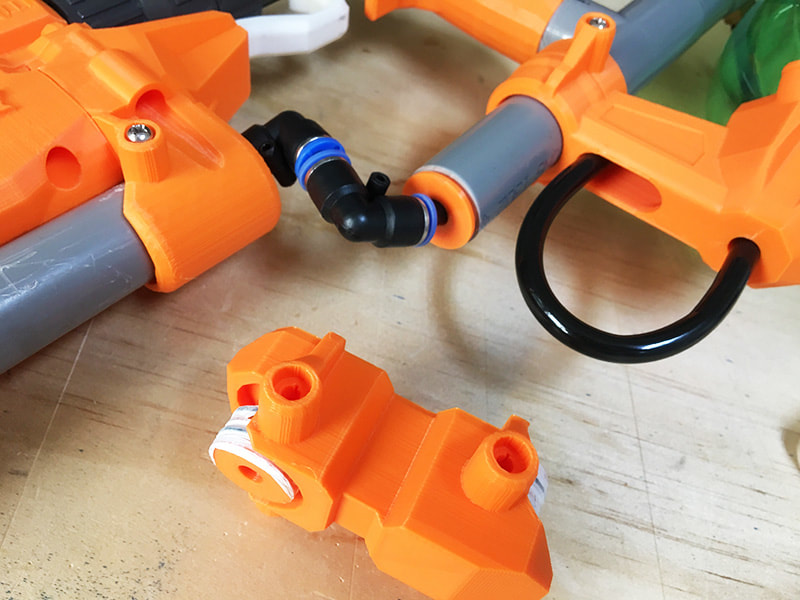

A few months ago, I spent a huge amount of time dealing with airtight, especially for the connector due to uneven surface and gaps, even with 100% infill. They made air sealing very hard and tricky. After a whole month of struggling, I overcame the problem eventually. The solution is to keep the airtight object from touching 3D surface.

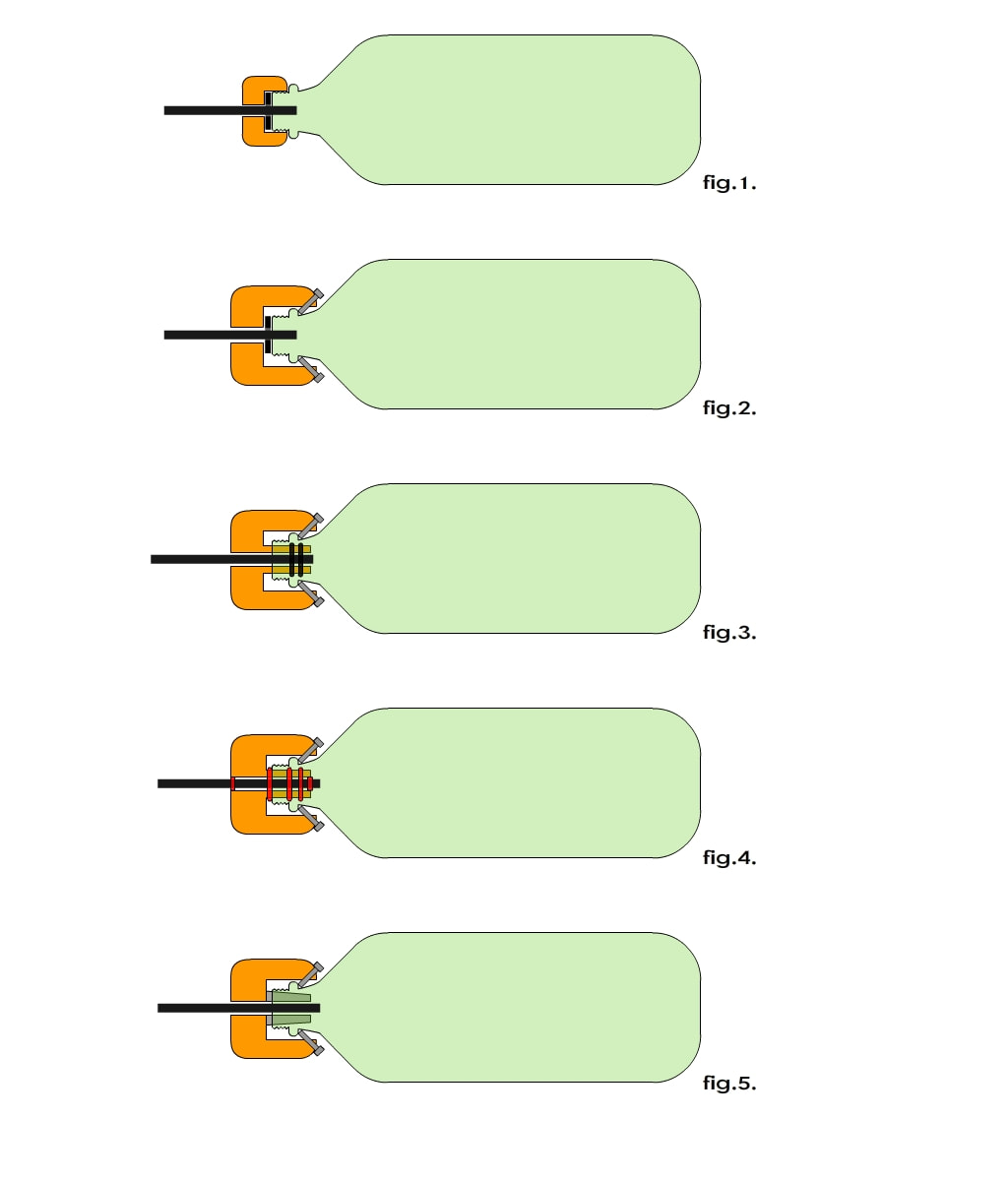

ver.1 (fig.1.) The connector is composed of a traditional cap and a washer. The airtight is incomplete and the cap could loosen up easily during movement. ver.3 (fig.3) A plug-shaped thingy is created, placed into the opening of the bottle, and fixed with 4 screws to keep the cap from loosening up.

ver4 (fig.4) Replaced the material of O-ring with silicone rubber and achieved 99% airtight. However, air leaks from the contact surface between PU tube and 3D printed part. Though the contact surface could be glued to reach 100% airtight, it causes a lot of trouble. Eventually, ver5 (fig.5) is able to keep all air pressure from the surface of 3D printed part by plugging the bottle with a cork (rubber stopper) and inserting a PU tube to achieve 100% airtight.

Airtight can be completed with 3 silicone O-rings yet, the contact surface between PU tube and 3D printed part wouldn’t be sealed.

Airtight can be completed simply with a cork, followed by a 3D printed part to fix it in place.

This is my recent progress and development for the last two months. Thank you!

- NerfHaven

- → Viewing Profile: Posts: 3DBBQ

- Terms of Service and Privacy Policy

- Code of Conduct ·

Find content

Find content