So can we have some pictures of a prototype/finished product, or have you not made a working physical design yet?

Also, could a stock be attached from the bottom and top of the handle?

Hello again Silly,

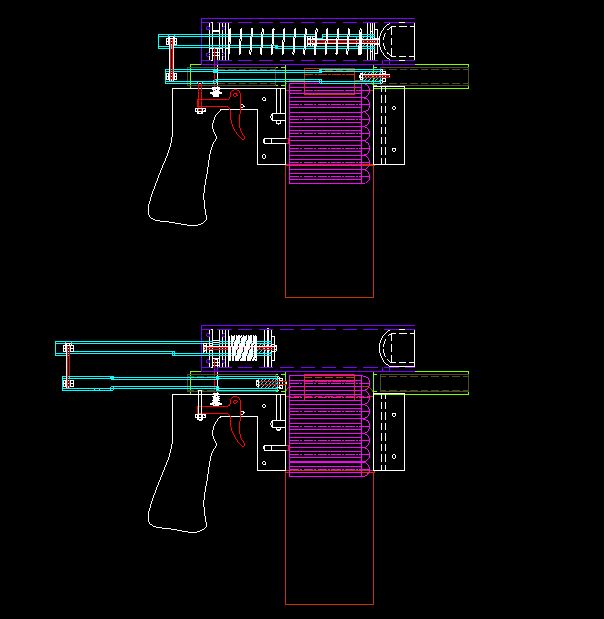

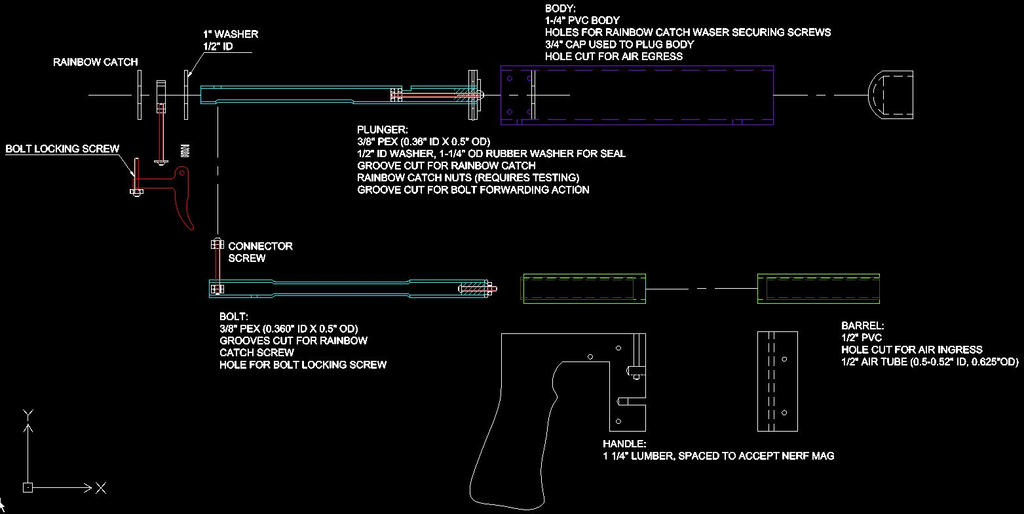

I haven't started the build yet, I wanted to make sure that my design had any merit before I spent any resources on supplies and construction. I'll probably start ordering parts later on this week with build and, hopefully, functional testing info to follow.

As for the addition of the stock, it's something I intend to incorporate later on as well, and should be pretty easy to do. Without changing the internals at all, and just the addition of the stock, a longer barrel and/or pump slide, this thing can be changed to a more rifle or shotgun style blaster. With some length alterations to the body, spring, plunger and bolt, you could make the body more length appropriate for those styles as well.

Edit: Hi, I've decided to try and get my hands on a piece of 1/2" Schedule 80 pipe, which has a nominal ID of 0.54" which is much, much closer to the 0.511" of the nerf dart without any modifications.

Find content

Find content