- NerfHaven

- → Viewing Profile: Topics: Birch

Birch

Member Since 23 Jan 2013Offline Last Active Aug 23 2024 08:48 AM

Community Stats

- Group Members

- Active Posts 181

- Profile Views 13,804

- Member Title Member

- Age Age Unknown

- Birthday Birthday Unknown

User Tools

Latest Visitors

Topics I've Started

Motors for Flywheel Blasters

17 March 2015 - 08:13 PM

Homemade Flywheel Blaster

08 March 2015 - 08:14 PM

As I understand, concept threads are not really allowed, but I have just so little desire to actually try it out this idea for myself, I thought I could just tell you my thinking and someone who knows more than me about electronics and stuff could try it out or something.

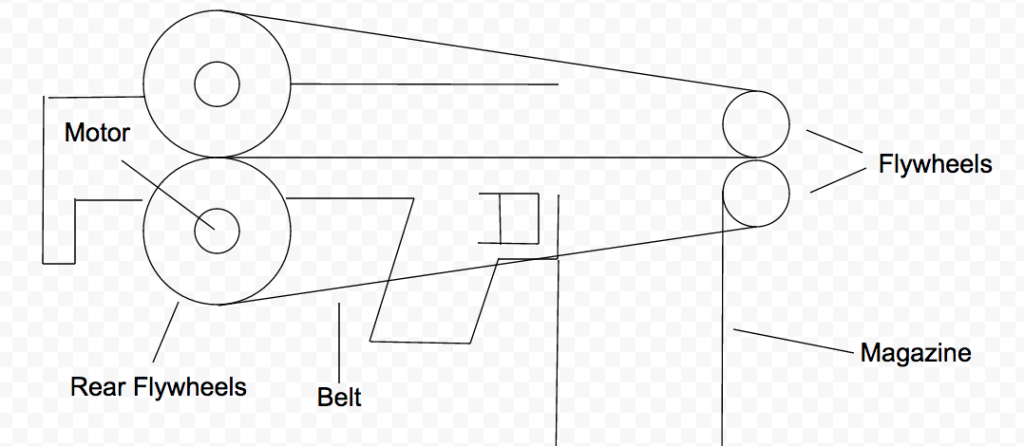

My basic idea is to move the location of the motors in a flywheel blaster. Doing this, one could in theory raise the revolution speed of the flywheels greatly, without using insane motors or equally insane batteries. By harnessing basic mechanical laws, this design would be able to compete with other plunger-based homemades in range and fps. Here is my basic design: [/URL][/img]

[/URL][/img]

Locating the motors in the behind the darts allows for their to be a mechanical advantage system of wheels and pulleys. This means I can spin the back motors at a slower or even similar rpm to what is required in a say a stryfe, and achieving much better performance. The motors would need to have really Of course this would add a lot more bulk to the blaster, but it would still be much shorter than a double rainbow, which this would be similar in size to.

The reason I have so little desire to try this out for myself is because I have no where near the amount of cash that would be needed to build this thing, nor do I have the knowledge or the patience to work with something like this. In addition, this thing would require either expertly crafted or 3D printed parts. I would love to see this idea put into practise by someone, and to see if my ideas would actually be practical.

Why do slug darts need to be made with washers?

29 March 2014 - 10:01 AM

Addendum, I have no problems with the weight punching through the head of the dart due to the manner in which I constructed my darts. The order of operations goes: burn hole, hotglue, weight, a little hotglue, while glue is still hot, a felt pad. This procedure encases the metal in hotglue, bonding it to the foam, not just letting it sit in the hole in the foam.

Stretching Foam

17 June 2013 - 06:43 PM

I also really like to make and use 3/4 inch darts for fun, so my question is, does stretching foam work the same with big foam, or does it have some weird effects on big foam?

I know these maybe be newbie questions, and I'm pretty sure someone will respond after only reading the above part, Why don't you just buy different foam? The answer is just that I don't want to pay for expensive foam on the forums, plus my parents are skeptical of the credibility of some of you(I don't). I also am just much more inclined of just modifying my current best materials foam because it is really great foam, it just degrades really easily when used it tight barrels. It is very firm and hard(gigity) right off the roll so if I could just make it thinner right off the roll it would be great foam.

Marshmallow blaster seal problems.

29 March 2013 - 07:34 AM

edit: I figured it out, but I have a new problem. The valve dosen't seal for a whole pump. When I open it up, the valve head is creating a airtight seal with the gasket, but together that seal doesn't really happen. Is it that the spring pushing on the valve head is too weak or is it something else.

the blaster in question:

http://a.tgcdn.net/i...low_blaster.jpg

- NerfHaven

- → Viewing Profile: Topics: Birch

- Terms of Service and Privacy Policy

- Code of Conduct ·

Find content

Find content