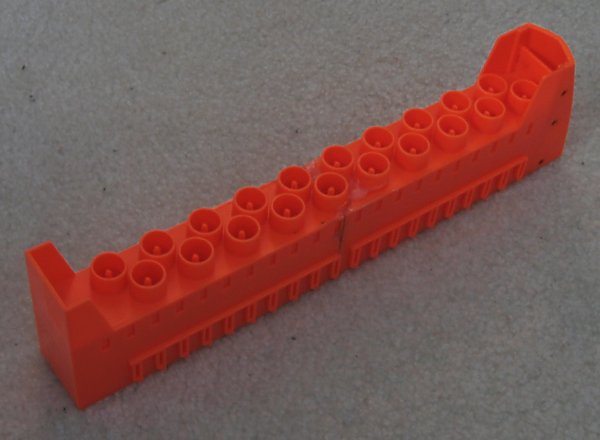

Admittedly this clip represents some of my weakest craftsmanship in the past year. In hindsight I should have used the mill, the bandsaw wasn't cutting straight. I had to buttress the joint from the inside using small pieces of polycarbonate, then solvent-cure the halves together in a vice. Then I filled the void with lots of hot glue to stabilize the joint.

The advancing teeth on the left side of the clip are spaced apart exactly 1/2-inch. So provided you make clean cuts and can attach the two clips together straight and at the right spacing the gun won't have any problem advancing the ridiculously long clip. Then you have to trim off the under side of the front of the gun using a saw and a dremel. Then apply electrical tape to the tooth-lock holes on the sides to prevent the clip from dropping back down after only a portion of the clip is emptied.

I spent most of today running tests on the gun using regulators and a compressor to determine to operating pressure level of the internals of the gun. The baseline operating pressure is around 30psi and I'm unsure of where the maximum pressure level is but I'm fairly sure it's atleast 60psi, if not higher. The tubing, piston, and trigger valve should be rated up to 125psi, but I won't be reaching that kind of pressure level.

More later. My current plan is to make a high-capacity backpack tank filled at 125PSI with an output regulated to 50psi to power the magstrike. The tank will have an input for a compressor or a portable 12v motorized pump I've been wanting play with for several months.

Edited by CaptainSlug, 03 October 2006 - 04:32 PM.