Edited by Daniel Beaver, 18 April 2011 - 08:34 PM.

Posted 20 April 2011 - 04:46 PM

Posted 21 April 2011 - 12:03 PM

Posted 21 April 2011 - 10:20 PM

Edited by diamondbacknf1626, 21 April 2011 - 10:33 PM.

Posted 22 April 2011 - 08:48 PM

Posted 25 April 2011 - 08:25 PM

Posted 25 April 2011 - 10:14 PM

Edited by SonReeceSonJensen, 25 April 2011 - 10:40 PM.

Posted 27 April 2011 - 02:31 PM

Posted 27 April 2011 - 06:05 PM

Posted 28 April 2011 - 04:43 PM

Edited by Merzlin, 28 April 2011 - 04:50 PM.

Posted 01 May 2011 - 07:25 PM

Posted 04 May 2011 - 02:04 AM

Edited by Jlego, 04 May 2011 - 08:29 AM.

Gears: Ice9 and I have a relationship similar to that of myself and Jax.

liska: You snuggles?

Gears: The nerfers most likely to engage in a threesome.

I've seen you use an arrowstorm!!

Posted 06 May 2011 - 11:14 AM

Posted 06 May 2011 - 10:01 PM

Posted 07 May 2011 - 04:03 AM

Posted 07 May 2011 - 08:33 PM

Edited by venom213, 07 May 2011 - 08:33 PM.

Posted 15 May 2011 - 01:52 PM

Posted 23 May 2011 - 07:16 PM

Edited by aj1234119, 23 May 2011 - 07:18 PM.

Posted 24 May 2011 - 02:45 PM

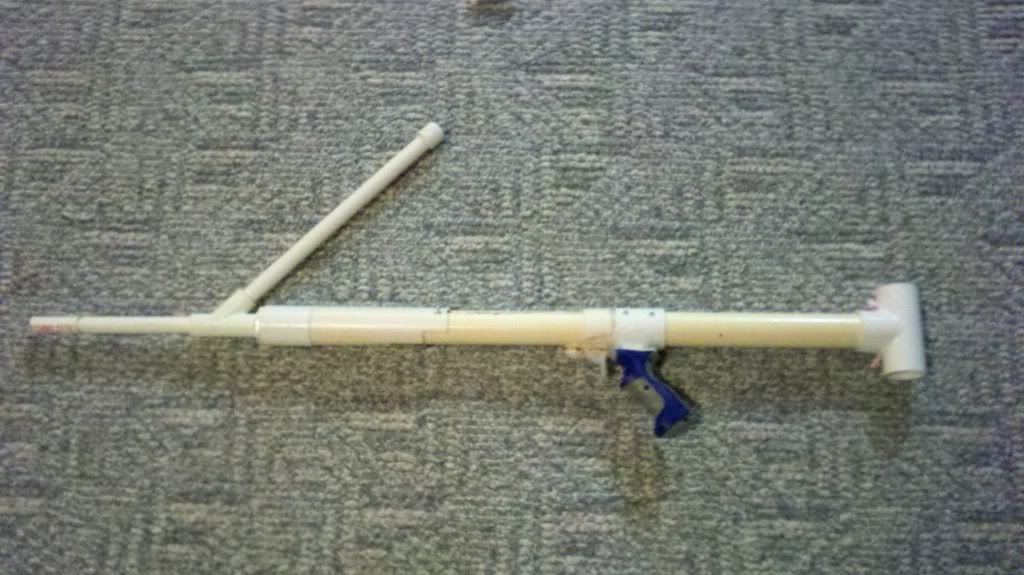

Or you can get it in purple!For anyone who can't find 1.5'' thinwall PVC for a pump grip, it its available from Flex PVC here, or you can use 2 pieces of a 1 and 1/4'' coupler glued into 2'' PVC.

Posted 24 May 2011 - 05:39 PM

Edited by Daniel Beaver, 24 May 2011 - 06:25 PM.

Posted 27 May 2011 - 03:33 PM

Posted 28 May 2011 - 02:01 AM

Unholy Three: DUPLUM SCRTA, DUPLUM PROBLEMA (2009)

But Zeke guns tend to be like proofs by contradiction

Theoretically solid but actually non-constructive

Rnbw Cln

Posted 28 May 2011 - 12:29 PM

I'm the only respectable person here. The rest of the NIC are pretty much just child molesters.

Posted 29 May 2011 - 12:01 PM

0 members, 2 guests, 0 anonymous users