I've been working on a new SNAP with the following goals in mind:

- Performance on par with current top of the line blasters

- Ease of construction using localy obtainable materials and simple tools

- Pump action

- Dry fire safe

- Safe internal mechanisms

This build is aimed towards the inbetweeners who have already built a SNAP, and are ready to graduate to The School of Pump Action. The only powertools required are a dremel and a drill, and the materials ought to be obtainable at your hardware store. The design is very heavily based on my previous SNAP, which was an evolution of Carbon's SNAP 2. I retained the clothespin trigger because it is a proven design, and the large catchface doubles as a priming surface.

I was going to make second prototype of this blaster to work out the chinks, but school is keeping me away from building. So here it is:

The front coupler

Parts:

- 1-1/4" PVC coupler

- 1-1/4" to 1/2" PVC reducer

- Solvent weld or super glue

Solvent weld these two pieces together. This will slide onto the body of the blaster later on. You can also use an internal coupler, but this is far less of a hassle.

The plunger head

Parts:

- 1-1/2" rubber washer

- CPVC cap

- Miscellaneous other materials.

- Some type of adhesive (goop works)

People use all sorts of plunger heads for SNAPS, but the core feature of all of them is a 1-1/2" rubber washer. I use a secondary 1-1/4" rubber washer as padding (to resist shearing), with a metal washer underneath for support. Make sure to use some adhesive to secure the CPVC cap to the plunger rod, otherwise it will eventually come loose (but don't do it until the gun is finished!).

The catch assembly

Parts:

- 3/4" PVC endcap, preferably rounded on the end

- 1/2" PVC endcap

- 1/2" CPVC coupler

- 1/4" metal rod

- 1" metal washer with 5/8" opening

This is based on the Preeminent Plunger Head (You could also use the basic design of the Superlative Plunger Head). The key difference from pull-back SNAPS is that you need to attach CPVC to both ends, so you will have to open up the back of the 3/4" PVC with a drill or a dremel so that the CPVC coupler sticks out the end. You can then just friction-fit them together (with the persuation of a hammer). You also want to put a washer on the front of this, but I could not find one at local stores with a large enough center hole to fit the CPVC. These DO exist - my last couple of pump-action SNAPS used these. You may also have to shave down the back edges of the coupler if it is not very flat - there should be no resistance when priming.

The 1/4" metal rod is the main support piece for the dry-fire system. You could probably use a smaller diameter rod, but... there is an awful lot of force on this piece. Do not place the rod as far forward as I did, otherwise the CPVC may break (as mine did).

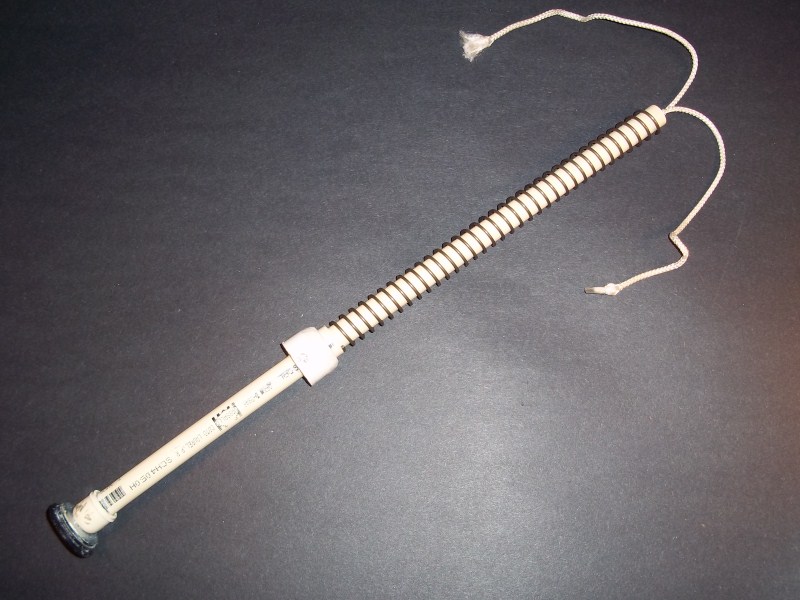

The rest of the plunger rod

Parts:

- string

- Spring

An overview. The rear section of CPVC is a stabalizer which keeps the spring from binding up like crazy, and which also acts as a sheath for the string. The string loops around the 1/4" metal rod in the catch, and both ends come out the back. Getting the string looped around the metal rod is a bitchy procedure: tape a small drill bit onto the end of the string, and drop it down the front (I hope you didn't glue that plunger head in yet), and then use some needle nose pliers to pull it through. Use some tape to tie off the ends of the string so it doesn't fray, and leave yourself plenty to work with.

I use a [k26] for this blaster. You can use whatever you want for yours - just make sure you think about how it will affect the dimensions of the blaster.

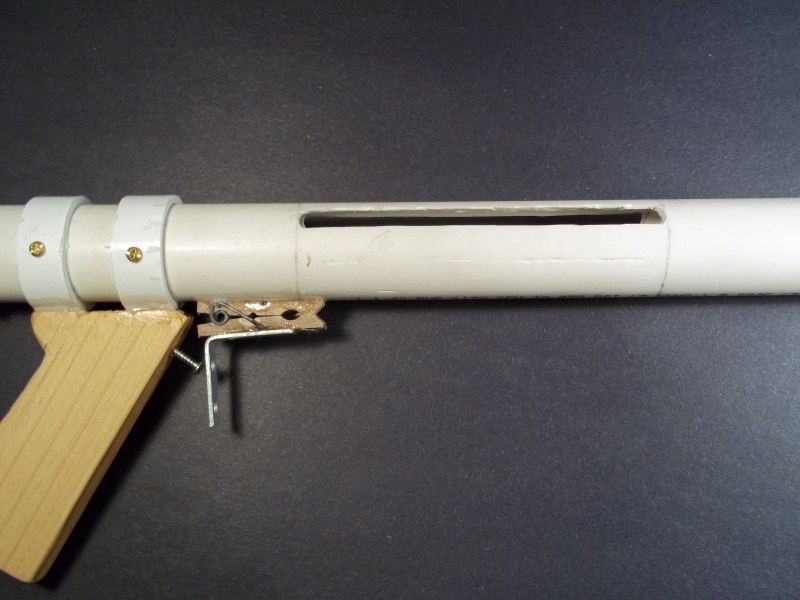

The slots

Parts:

- 1-1/4" PVC

These are tricky. The slots need to be offset enough so that the priming rod clears the plunger rod (about 5/16th of an inch away from the centerline in the case of CPVC). The best method is to drill a pilot hole, then twist the drill sideways and push it through the other end. Once you have opened up four holes, you can just slide a dremel along the length of the body to cut out the slots. A diamond cutting disk works extremely well for this application. If this all sounds confusing to you, just look at the pictures and figure it out on your own.

The grip

Parts:

- 1-1/2" thinwall PVC

- A big long bolt

The bolt pushes against the catch face to prime the blaster. The little square slot gives clearence to the clothespin, which will always overlap the grip somewhat. 1-1/2" thinwall PVC slides freely over 1-1/4" PVC, and is a great grip material.

The spring rest

Parts:

- 3/4" Endcap

- packing tape

- screws

Use a 5/8" wood bit to drill a hole in the end cap, so that the CPVC stabilizer slides freely through it. Wrap a few layers of packing tape around it until it is snug in the barrel (packing tape is superior to e-tape, IMO). A couple of screws act as a rest for this piece. You might want to thread the string through this piece before you insert it, as it gets annoying to deal with otherwise.

Where to put the string stop? Simple: put the plunger rod and spring in. Slide the spring rest down the length of the plunger tube until the catch face is 1/2" away from the priming bar; drill holes and secure it (might take a few tries). You don't want any compression in your spring when the plunger head is all the way forward - we are trying to prevent the plunger rod from impacting the front of the blaster or the priming bar.

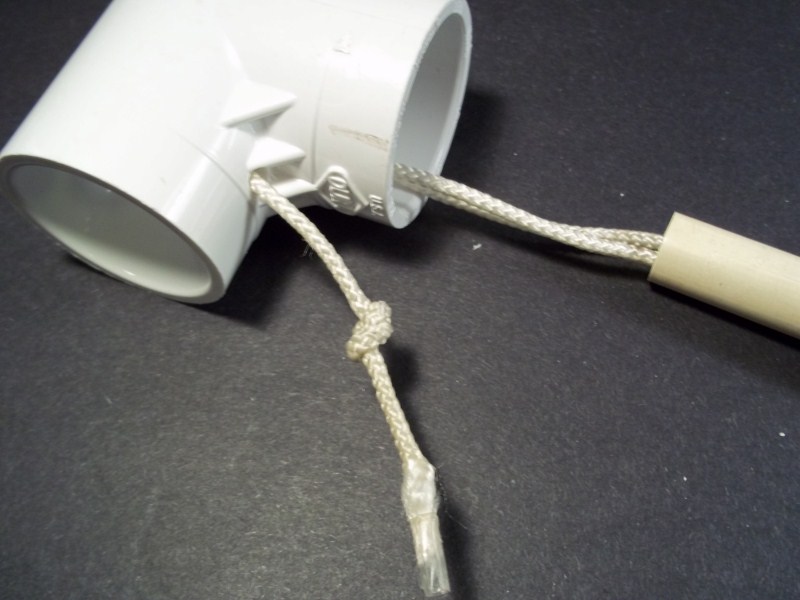

The string stop

Parts:

- 1-1/4" tee

This end of the mechanism is identical to the dry fire system used in the Rainbowpump. The string loops around the end, feeds through the holes, and is anchored by some figure 8 knots. Once the blaster is built, you will have to spend some time adjusting this so that the length is right. When you have the length right, the blaster will be noticibly quieter when you fire.

Dimensions

These are for a 5.5" draw length (I use a [k26] spring). If you are using an internal coupler on the front, make sure that you reference your dimensions against the back of the coupler. Your fittings might be a different size than mine as well.

The handle

Someone is going to ask about this, so I'll just post it. The handle is just a piece of wood I cut with a jigsaw and sanded. The two rings are cut off ends of a 1-1/4" PVC coupler. I do not recommend this style; just use a snap-on handle, or do what Rork did in the Snapbow mk5 writeup.

Finished blaster

Attach a clothespin trigger. Adjust the string stop, lube with some silicon grease and use some goop to glue the front coupler onto the blaster. Add hopper clip and loooong barrel (about 14" seems about right with a footlong clip). Ranges are typical for a [k26] powered SNAP: about 130" with domed darts and an 18" speedloader.

Edited by Daniel Beaver, 19 April 2011 - 05:28 PM.