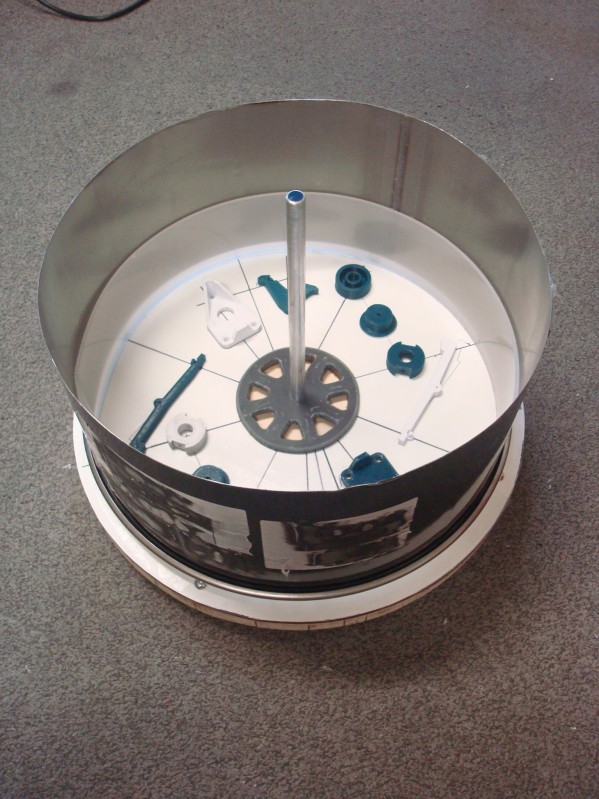

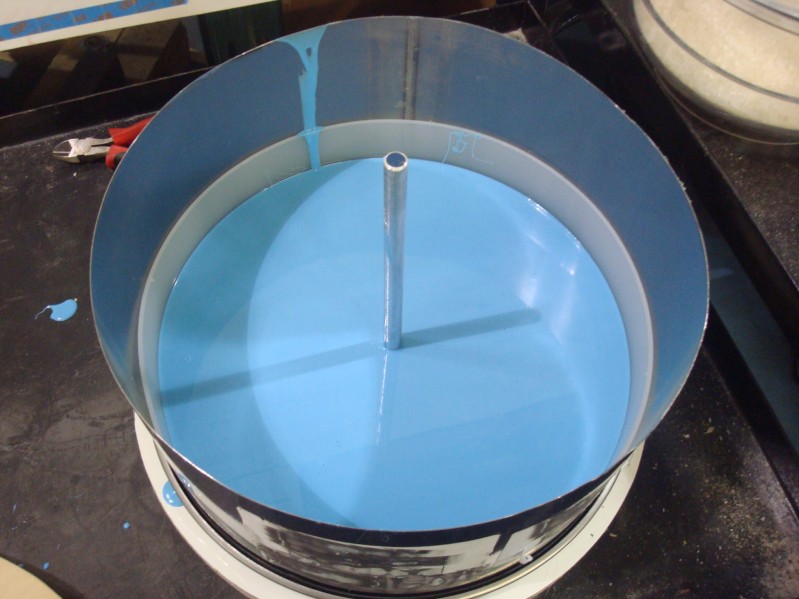

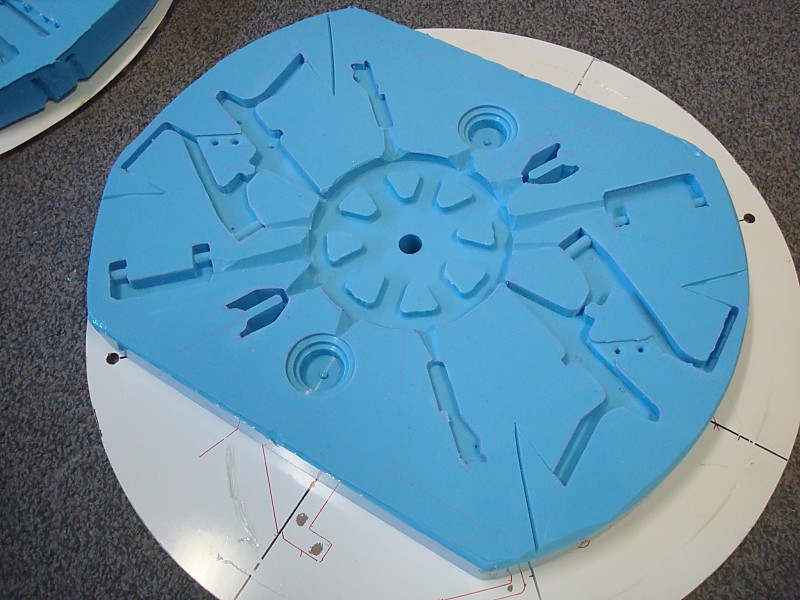

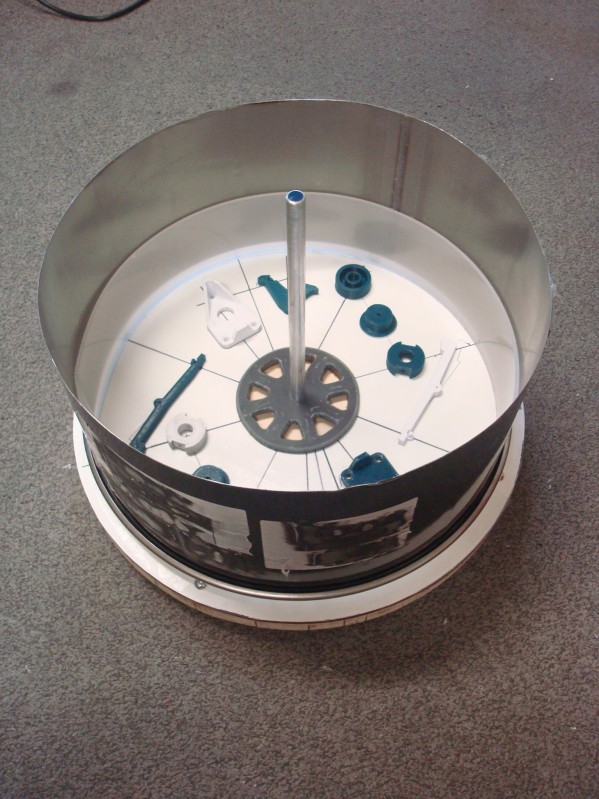

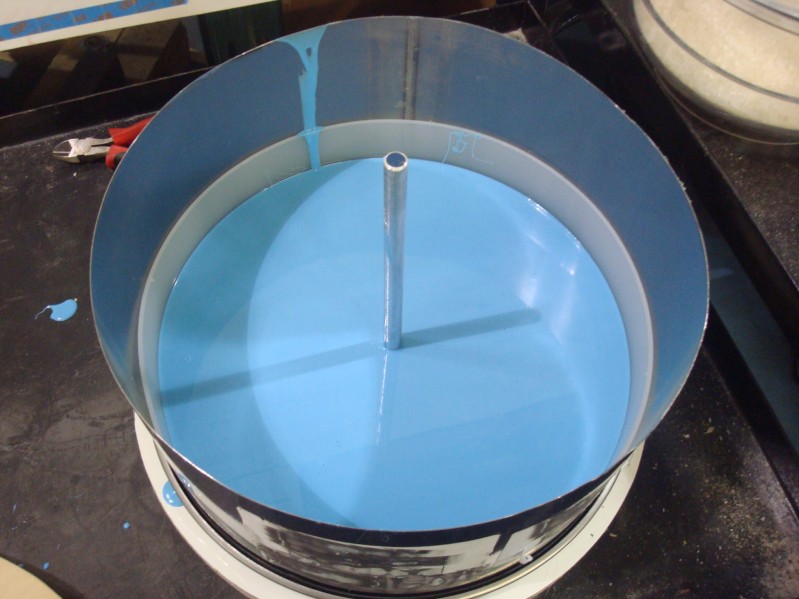

Well, this is a big post. I cut the top lip off of a 10 gallon drum and used it to hold together a strip of polypropylene into a hoop. I then hot-glued the polypropylene to the dry erase board. In future I won't bother trying to reuse or save the dry erase board because it was not worth the effort just to try and preserve $3 worth of plastic-coated fiberboard.

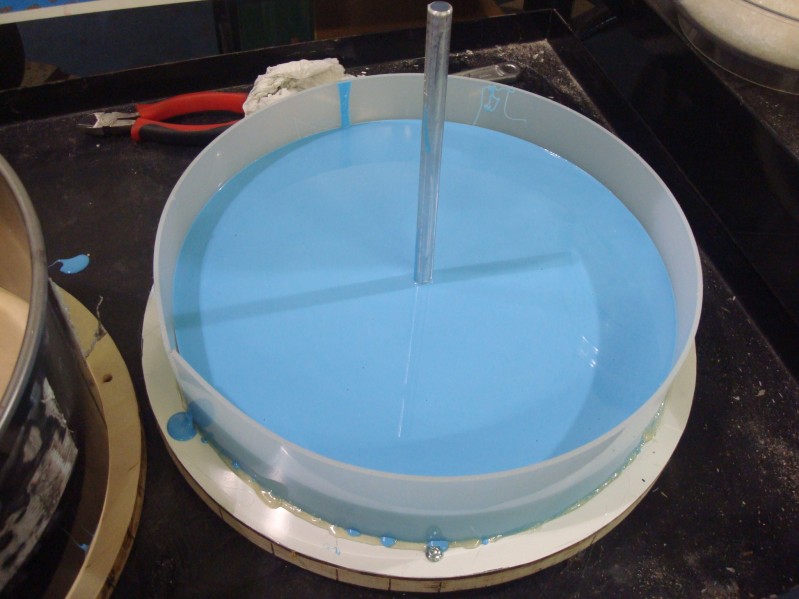

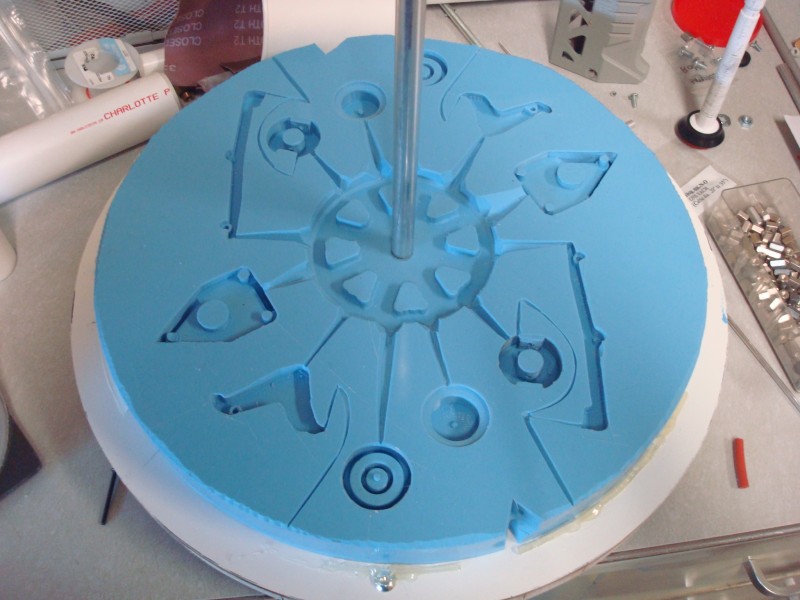

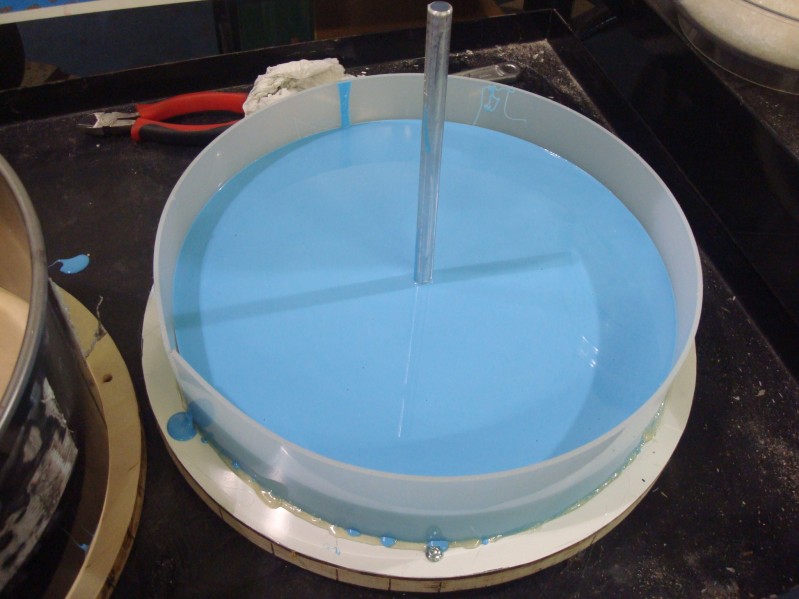

The pour was a big challenge. I needed to pour 8 pounds of silicone, but the vacuum jar I have can only reasonably hold 3 pounds at once when de-airing. So I have to measure into two containers, combine/mix, then split the mix into three other containers to de-air. So having 45 minutes of pot life for these molds will be vital.

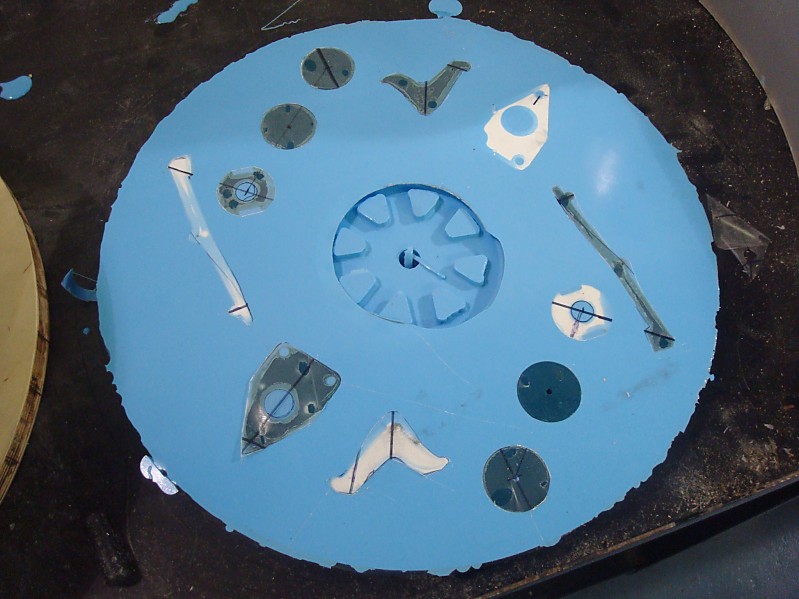

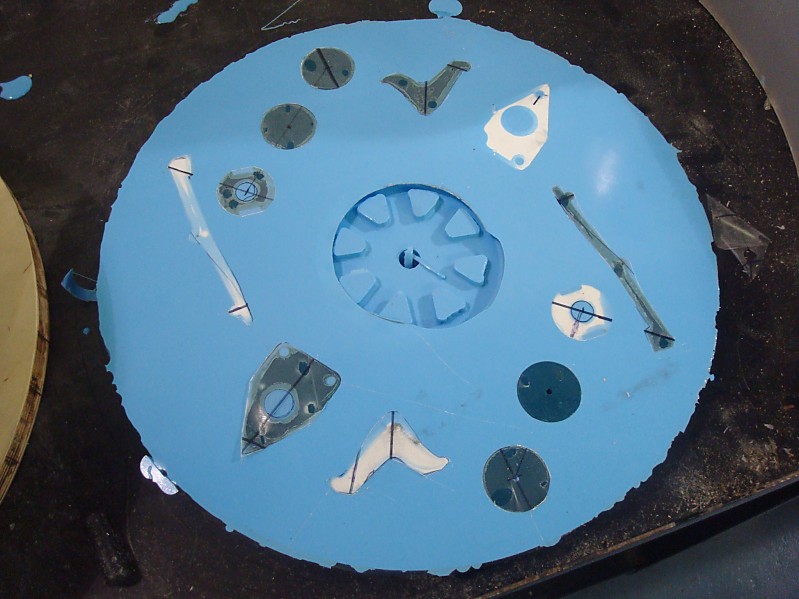

After 24 hours of curing I can remove the drum top and pry the polypropylene off.

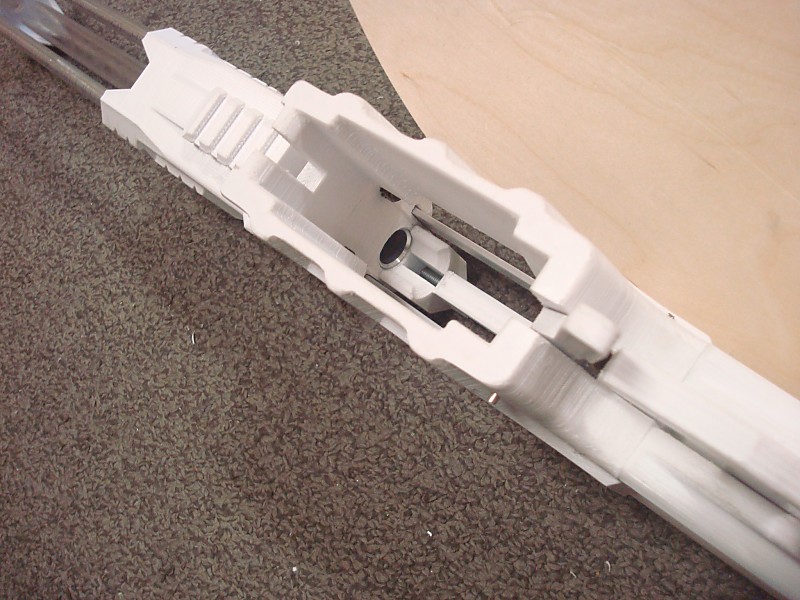

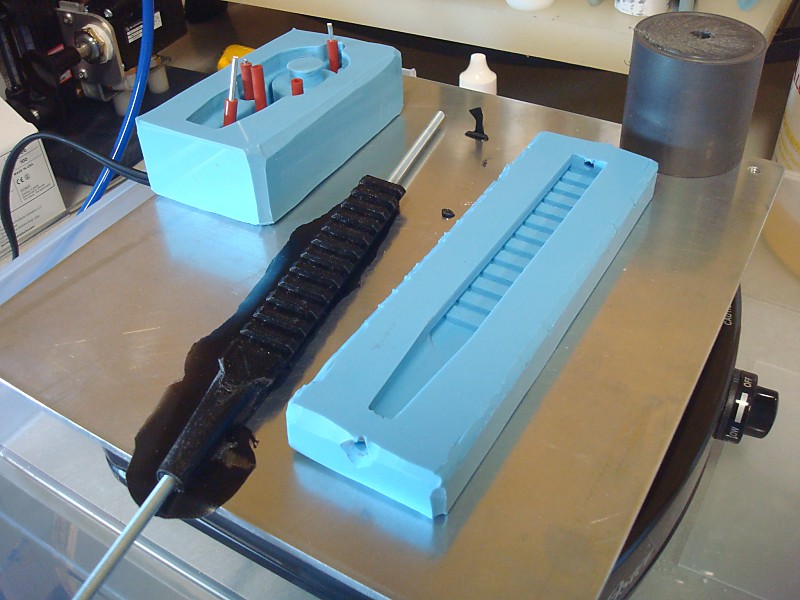

The majority of the features were duplicated. Only some of the 1/16" diameter holes didn't end up with full length nibs, but they still got enough to act as a center for post-drilling of cast parts. I forgot to put mold release on the aluminum cross-pins I had inserted in two of the parts, so those were difficult to get back out.

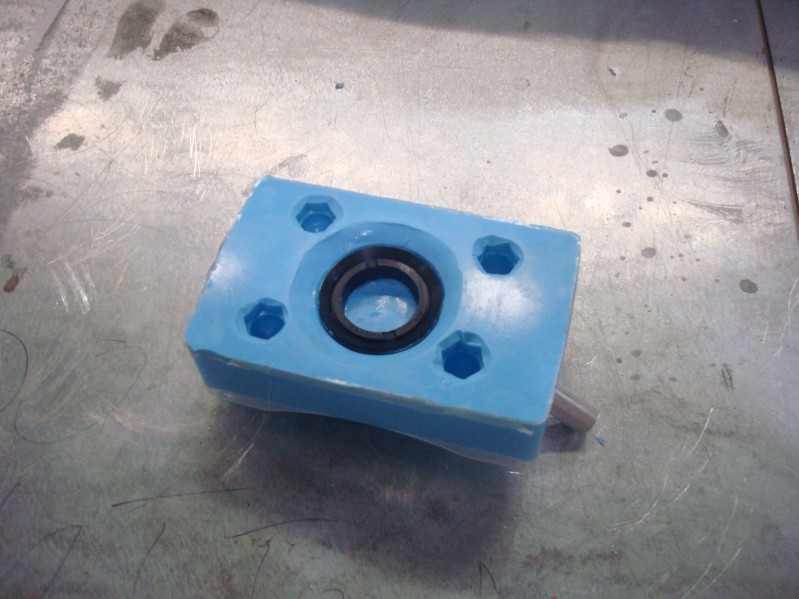

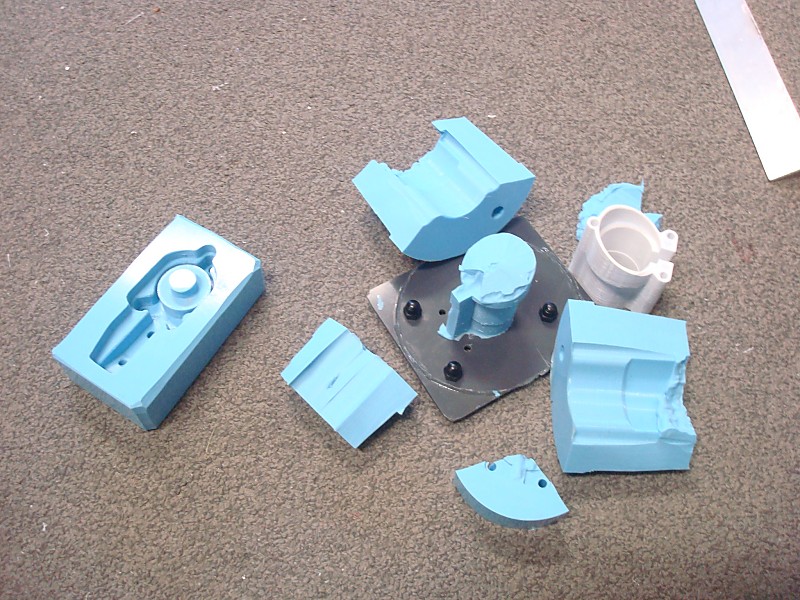

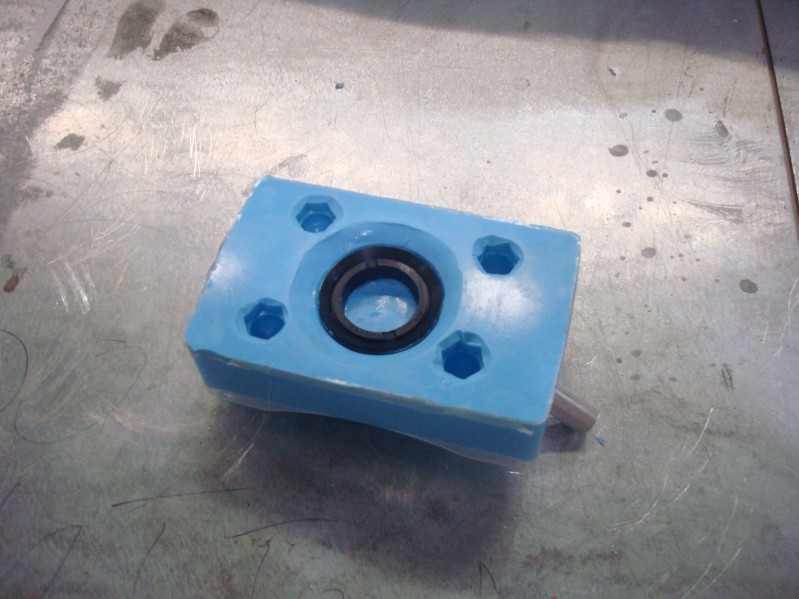

I also attempted another mold. This one did not work at all.

I'm hoping to cast my own skirt seals, and making a mold for them requires a 2-part design. This was my first time using sulphur-free modeling clay to produce a mold. Things appeared to be fine until I got to the skirt seal.

It turns out that Buna-N is chemically incompatible with casting silicone and none of the mold features cured against the rubber. So this was a big flop. I will have to use a different material to make the mold, or make a dummy skirt seal by 3D-printing or machining.

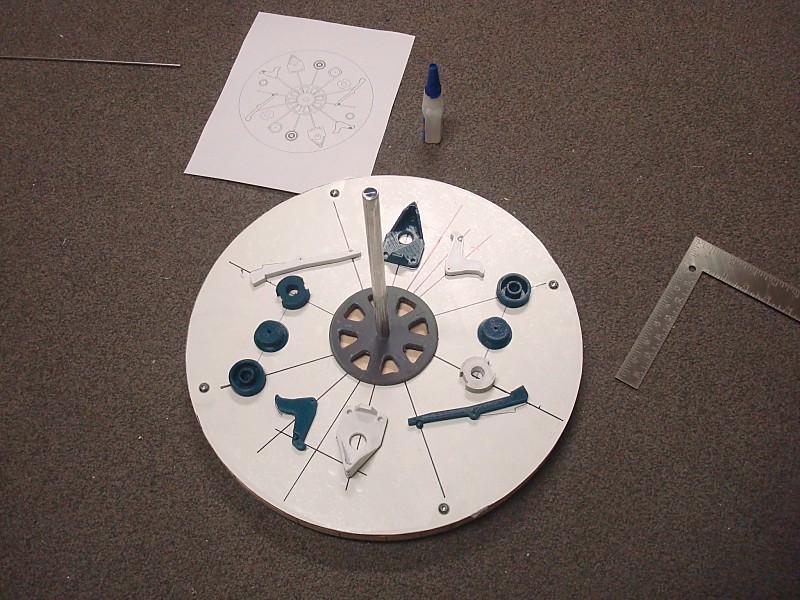

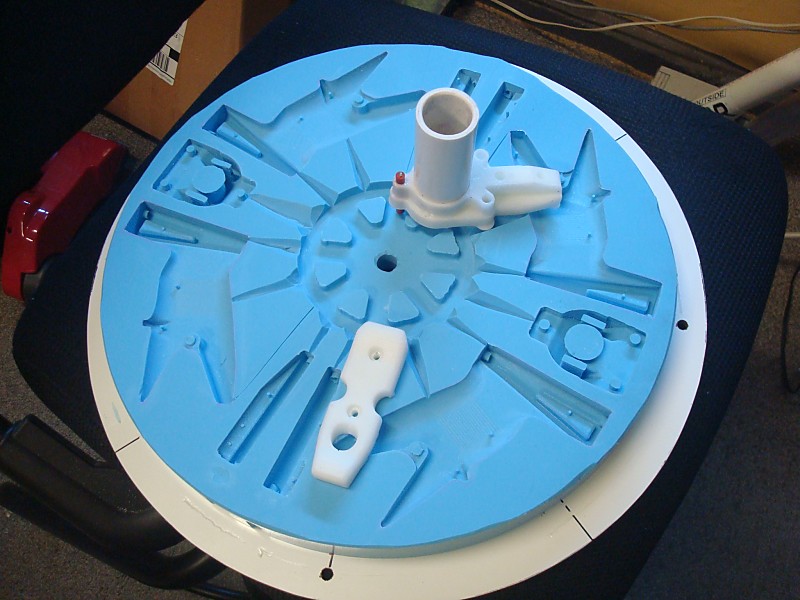

But that's no big deal. Now I have one of three spincasting molds. I just have to clean up the flash and cut my runners and vents.

I also just ran an estimate for how much silicone I'm going to need to complete the mold set. I have to buy at minimum 24 more pounds of it.

The little critters of nature, they don't know that they're ugly. That's very funny, a fly marrying a bumble bee. I told you I'd shoot, but you didn't believe me. Why didn't you believe me?