Hole Door

Hole Door

Hole Door

Posted 06 July 2016 - 03:42 PM

POPULAR

Posted 06 July 2016 - 03:53 PM

I like the design a lot, but curious how easy it is to open or close the door. Is the tension adjsutable?

Can we make those magic ball valves?

I like seeing all these recent new hopper top designs, first the magnetic cap and now the hole door.

I'm Van, the weird kid with a box

Triggered as fuck and ready to gun you down

#NoBarrelTapsNoMercy

#GoFastGoFurious

"Stone Cold Operator of Death" -Clownie

Posted 06 July 2016 - 03:56 PM

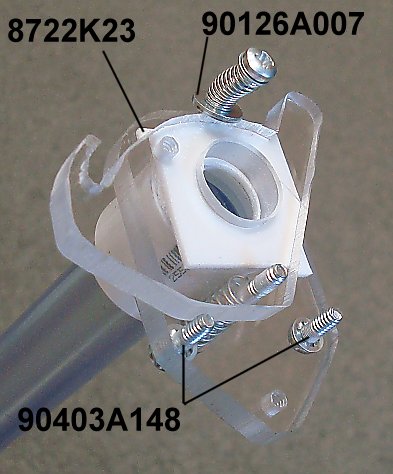

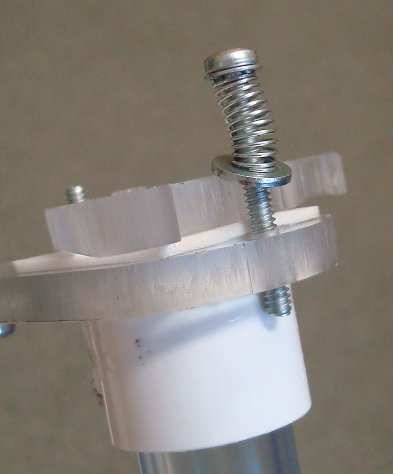

The springs are only there to keep the door pressed level against the foam gasket. You adjust one spring or the other to make sure that the seal doesn't have any gaps. The latch on one side allows that spring the disengage.

I was going to use an o-ring, but the inside of the coupler doesn't provide a good seat for any standard sizes that exist. The foam is easier to cut to size anyways and it doesn't require lubrication.

I also originally had an extension spring acting as a detent to hold the door in either position against the hard-stops, but it doesn't seem to be needed.

Posted 06 July 2016 - 07:54 PM

Would the foam seal degrade over time and how well does it seal under firing pressures?

I'd love to make a replacement for ball valves to reduce how bulky the setup is, but one nice thing is the ball valve + extended leverage arm setup I have has lasted ~5 years without requiring any maintenance.

Posted 06 July 2016 - 08:40 PM

This particular part number is the same polyethylene closed cell foam we use to make stefans, it's just available in 1/16" thickness and includes an adhesive backing. You can toy with other foams or gasket materials for this purpose at your leisure. I've used it for compression seals at very low pressures (under 10 psi) before for a few work-related projects and it's held up admirably.

I cannot detect a range difference between this homemade "knife valve" and a regular ball valve. I'm going to buy a ball valve and lube it up as a backup option, but I'm very happy with how easy this thing is to open and close just by nudging the lever on it. We'll see how well it does at Apoc. I might bring a few extras for others to try/buy as well.

If anyone else is willing to be a guinea pig on this in particular just let me know. These are piss-easy to make.

Posted 06 July 2016 - 11:50 PM

I cannot detect a range difference between this homemade "knife valve" and a regular ball valve. I'm going to buy a ball valve and lube it up as a backup option, but I'm very happy with how easy this thing is to open and close just by nudging the lever on it. We'll see how well it does at Apoc. I might bring a few extras for others to try/buy as well.

If anyone else is willing to be a guinea pig on this in particular just let me know. These are piss-easy to make.

Posted 07 July 2016 - 01:03 AM

Would the foam seal degrade over time and how well does it seal under firing pressures?

I'd love to make a replacement for ball valves to reduce how bulky the setup is, but one nice thing is the ball valve + extended leverage arm setup I have has lasted ~5 years without requiring any maintenance.

You could just use tighter spring to give it more bite, Maybe a Century C-528, or maybe a .035 gauge spring.

I'm thinking if the 2 pieces of polycarb were solid enough with tight enough tolerances to hold a seal if pressed together..... and the pivot also had a high yield .028-.035 gauge spring (like a c 528 century spring or a Hilman #143) it might have enough of a seal by itself.

Also, Slug, great work recently, been showing it to a lot of my associates on FB.

....Fear of a Nerf Planet!

Posted 07 July 2016 - 07:19 AM

3DBBQ/JSPB made something similar to this as a 3d printable part. Unfortunately, he's charging for it and seems to stipulate non-distribution.

Same deal and the other way of making a knife-gate valve. His just uses an O-Ring and seat. The seat presumably is to overcome the rough texture of the printed parts.

Update: So here's the weird thing with this valve that's interesting. The hole in the lower plate is drilled a fair amount larger than the hole in the valve door. What happens when pressure builds up inside the hopper is that the foam gasket acts as a diaphragm and puckers out like a set of lips. It does this without ever leaking or losing losing contact with the valve door.

I tried to take a photo of this, but it's proving difficult. So I'm also providing a cutaway diagram. It appears that I can reduce this behavior by adjusting the spring tension further, but it appears that the disparity in the holes in the plates is unintentionally beneficial.

Posted 08 July 2016 - 04:56 AM

A little shy on Nerfhaven, always have been, but I think this is a really good idea, so here it goes...

How about making the spring loaded screw at the load face stationary, back the washer with a #6 nylon washer a stationary screw. Crazy idea, removes the margin of clearance that the spring provides, but I have seen lots of Cigar cutters with no give, I think it might work.

Edited by Cartaya, 08 July 2016 - 05:18 AM.

....Fear of a Nerf Planet!

Posted 12 July 2016 - 09:06 PM

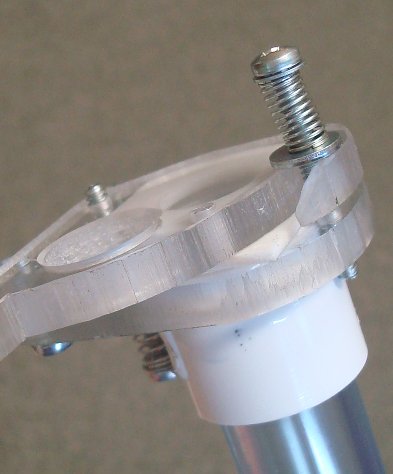

You may be correct, the spring on that screw is likely to be unwarranted and just a thrust washer might be all that is needed.

Once my other project is buttoned up I'll probably make of batch of these.

Edit: Just made another one. Cartaya's intuition was correct and the other spring isn't needed. I also learned that the foam gasket has to be as a big as possible. The edges of it don't like being pulled in, so the more area you cover with the gasket the more resistant to wear it will be.

Edited by CaptainSlug, 14 July 2016 - 03:49 PM.

Posted 14 July 2016 - 03:19 PM

That is awesome, I'm really glad to help. Makes sense with the gasket being larger so the door doesn't pull it in and try to fold the edge of it. I wonder if rounding the edges of the seal, the side that faces the door, if that would also help. But it sounds like you got it under control.

....Fear of a Nerf Planet!

Posted 15 July 2016 - 09:45 AM

Posted 15 July 2016 - 09:59 AM

The version with a single spring works fine.

Now the ultimate question: Does it work with no springs at all? I'd also thing making a plastic-foam-plastic sandwich would be the best durability possible. Laminate your foam pad to the plastic then do the machining so it's the same size.

Posted 15 July 2016 - 10:05 AM

Yes, it could work with no springs. You simply need to use thread-lock on the screws and tighten them until you reach the point where they're compressing the parts together just enough to seal against the foam.

If you want to make such a sandwich the recessed area or pocket for the gasket needs to be less thick than the foam because the foam only seals when it's under a certain amount of compression. I don't think this shim or surround would really be needed though. The only part of the foam you need to avoid stressing are the edges, as that yanks on the foam and adhesive backing.

Posted 15 July 2016 - 11:31 AM

If you want to make such a sandwich the recessed area or pocket for the gasket needs to be less thick than the foam because the foam only seals when it's under a certain amount of compression. I don't think this shim or surround would really be needed though. The only part of the foam you need to avoid stressing are the edges, as that yanks on the foam and adhesive backing.

I poorly worded that. Cut the bottom part of the door (gasket + plastic), then cut the upper half normally. You shouldn't have edge problems since there isn't anywhere for the gasket to shear since the door is always in contact with gasket+plastic and there isn't anywhere for it to get going on just plastic to take the gasket out.

Posted 20 July 2016 - 03:36 PM

The only downside I've really encountered so far with these over the past few weeks is that it's not a good idea to store these tensioned in the closed position for too long. The foam takes a fair amount of time to rebound, so if you've dimpled the shape of the hole into one spot of the gasket, that raised bump will push harder than the rest of the gasket. So you have to up the compression from the springs/screws to get it to seal again. There's a fine balance of enough compression to seal, but not enough to make actuating the door too difficult.

So for anyone that makes one of these for themselves the solution to this issue is one of the following.

Posted 21 July 2016 - 04:18 PM

Posted 22 July 2016 - 07:42 PM

The Hole Door "Birdo" breech. Guaranteed to make any blaster 300% uglier. Act now and yours will come with FREE GOOGLY EYES.

Also, no springs.

Posted 22 July 2016 - 08:09 PM

It's so functional-looking, it's cool.

Posted 22 July 2016 - 08:21 PM

It's so functional-looking, it's cool.

Functi-cool is the polar opposite of Tacticool.

Now I just have to find a way to make it so much more ugly that it becomes ironically cool.

Posted 03 August 2016 - 07:11 PM

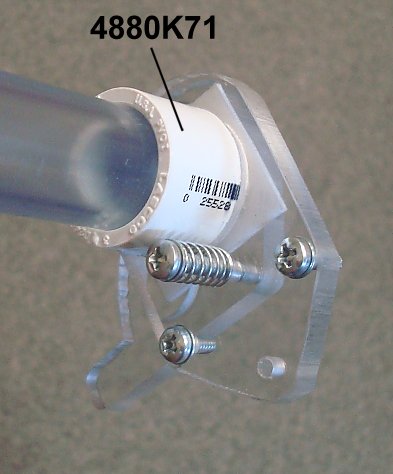

I just finished making 15 Hole Doors. You can make them without springs, but they don't work nicely without washers. And one spring and one washer works the most predictably, with the spring holding onto the door itself.

All of these were made with 1/8" thick foam, which should hold up much better than the 1/16" foam.

I also made the base plates out of grey PVC so as to ensure that the PVC cement would adhere them securely to the pipe stubs.

Posted 05 August 2016 - 02:55 PM

A Hole Door with two pipe stubs for Zorn's funnel.

Posted 06 August 2016 - 01:59 PM

sorry for how I was a year ago

Posted 06 August 2016 - 02:55 PM

It took me a couple hours to make my first one. It is very nice, although the one thing I like about ball valves over it is the larger opening for darts. I might make another door scaled up a little bit, but even without that, I think I like it better than the ball valve.

Posted 07 August 2016 - 06:40 AM

My god. How hard are they to make, and is it really worth the hassle?

-Montymarks

It's just drilling and tapping some holes in two plates, then cutting them out. The only "trick" is doing a good enough job cutting the gasket, which require a 9/16" or 5/8" hole punch. These are easier to open and close than ball valves, they won't munch darts, and the door being clear makes it easier to see all the way down into the hopper even when it's closed.

It took me a couple hours to make my first one. It is very nice, although the one thing I like about ball valves over it is the larger opening for darts. I might make another door scaled up a little bit, but even without that, I think I like it better than the ball valve.

You can make the through-hole 9/16" or 5/8". To go larger than that you just need to cut away enough of the door to adjust the location of the hard stop so that the door can seal the larger opening in the gasket.

Community Forums →

Homemades →

Clarification of differences between Hoppers, RSCBs, Choppers, and BRIStarted by Silly, 17 May 2021 |

|

|

||

Community Forums →

Homemades →

Project 10Started by snakerbot, 05 Jul 2019 |

|

|

||

Rival

Community Forums →

Modifications →

Nerf Rival Zeus SImple Hopper ModStarted by YEETthatdart, 24 Nov 2018 |

|

|

||

Community Forums →

Darts and Barrels →

"Cascading Compressed Air" Design for a modular repeating barrStarted by stuck by stefan, 10 Feb 2018 |

|

|

||

Community Forums →

Homemades →

Alternatives for a ball valveStarted by Daniel12, 30 Mar 2017 |

|

|

0 members, 1 guests, 0 anonymous users