Thanks for the comment moosa.

Bob, that is a good summary of what I've tried to say. Thanks for stating it more explicitly than I have.

Now for my latest novel...

Given the amount of variables that still exist, my inclination is that it would be more "efficient" to guess and check for barrel lengths, and probably without any resulting loss in performance over using your tables.

These tables are far more powerful than testing due only to the time involved in testing. At worst these tables reduce the number of tests to perform. There also aren't too many variables in the pneumatic problem and a number of assumptions can be made that are valid in general.

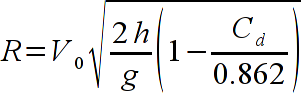

What is the conventional way to make an air gun perform at peak efficiency at a certain level of performance? One might make a gun of reasonable dimensions and keep increasing pressure until the desired performance is reached. This doesn't result in an optimal configuration, so to get an optimal configuration, one has to start adjusting other parameters. This gets very complicated; these tables provide a shortcut.

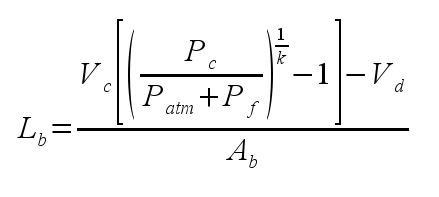

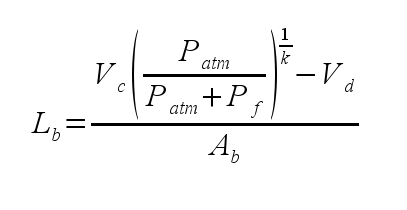

Finding the ideal barrel length for a gun of a fixed gas chamber volume (i.e. a modified gun) is a little more straightforward. But this often will result in configurations where the darts are too light for peak efficiency. The tables provide insight here to not only reduce testing time, but to also let you know that your gun likely will perform better if you increase dart mass.

As for the limitations of the model and this approach, the model make a number of assumptions that are valid for guns people would want to use. Ideally, valves open quickly, dead space is small, and there are no leaks. If one is going to take the time to design an efficient gun, surely these assumptions would be valid, so I see no reason to include other assumptions in a relatively simple table like this.

The assumptions I've made in this model are valid for at least 90% of good performing Nerf air guns. Additional variables aren't necessary.

Given how rigorous you've attempted to be here, it would be a good idea to evaluate for yourself the actual consistency, accuracy, and overall benefit of using your table method over the conventional means before you pin this as "useful."

I'll admit that I have not had the time to verify the accuracy of the tables. This will be done when I have the time. I'm very reasonably confident in the tables, however, as simpler simulations I've written were plenty accurate and I checked my work many times before implementing the simulation.

I don't think you're going to get any significant improvements in results via this method compared to conventional methods (let alone the extra work involved and whether or not anyone cares about 5 extra feet).

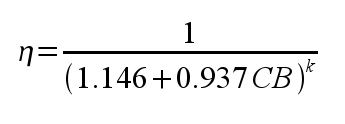

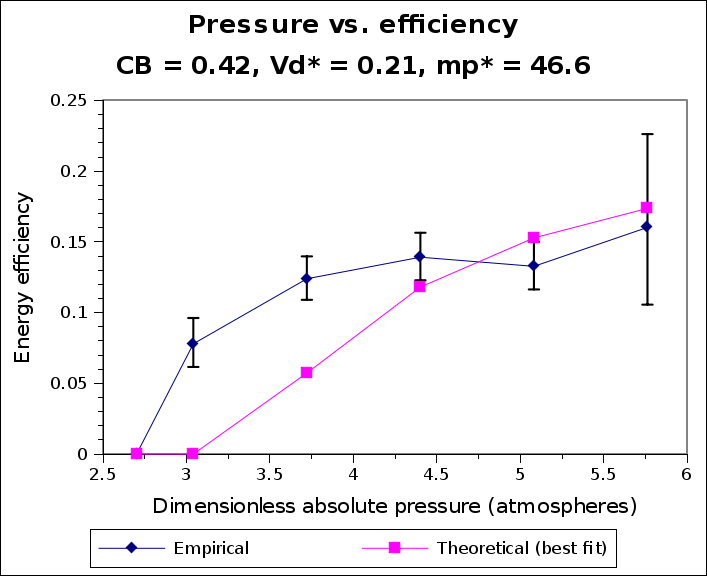

The performance increase can be very substantial. Most Nerf guns have efficiencies of less than 20%, even with optimized barrel lengths. A quick glance at my table shows that efficiencies over twice that are possible. This does far more than increase range by 5 feet. I'm not even interested in improving range; I want to keep range constant while reducing the amount of energy I put in the gun. That's practically impossible outside of simulation, as I've tried to explain above.

And even if you could account for as many variables as possible, there's always variation within the components of the blasters themselves, which you have no control over and would further skew actual results.

Uncertainties in measurements and the fact that we can't control for everything do make test results variable. But, this is a fact of empirical measurement, and is no reason not to use a model.

I don't want people to come in here and be dazzled by all the mathematics and think this is the Barrel Length Guide thread 2.0, this time made by a Nerf god.

Me neither. In fact, I waited a few weeks before posting this because I wasn't sure how people would react. I'm thankful that no one has accepted this as some sort of dogma.

Also, if it was unclear, my post in the recent barrel length thread was partly a joke.

Edited by Doom, 15 May 2010 - 06:26 AM.