Last weekend Falcon and I spent a great deal of time working on Bringing our Signature Primaries back to life, In his case, finally refining his beastly X-bow...I'll let him share it with you when it's ready... and I finally decided to sit down and get to work on The Second coming of Sicklefin.

I had learned from the first one, that Gratuitous amounts of epoxy is not a viable way to modify a manta shell for long term heavy use. Hence why I had to rebuild it's upper half a couple of times. Epoxy simply doesn't allow for enough flex, and falls apart if you bend it too much. I also decided that most other adhesives would suffer from other similar weakness, or from lack of the required strength to hold it in place.

Because of that, I decided that this time, I'd most likely be fabricating an entirely NEW upper shell for Sicklefin II. At First, I considered making it out of a single piece of sheet plastic. But there were many reasons that eventually deterred me from doing that.

* It dances down the line of questionable war legality

* It makes fabrication of a nerf shield Too easy, which would also put legality into question

* Although it would help avoid some of the flexibility issues, it would still suffer from many of a Stock Manta's weakness related to stress points, many due to the fact that it is one solid piece.

* It's rather costly for a large enough plastic sheet, and if I screwed up, it would be a pain to replace.

* It would be equally challenging to adjust it's contours to be similar to that of a stock manta.

* A single sheet would look very plain, even when ornately painted

* Ect...

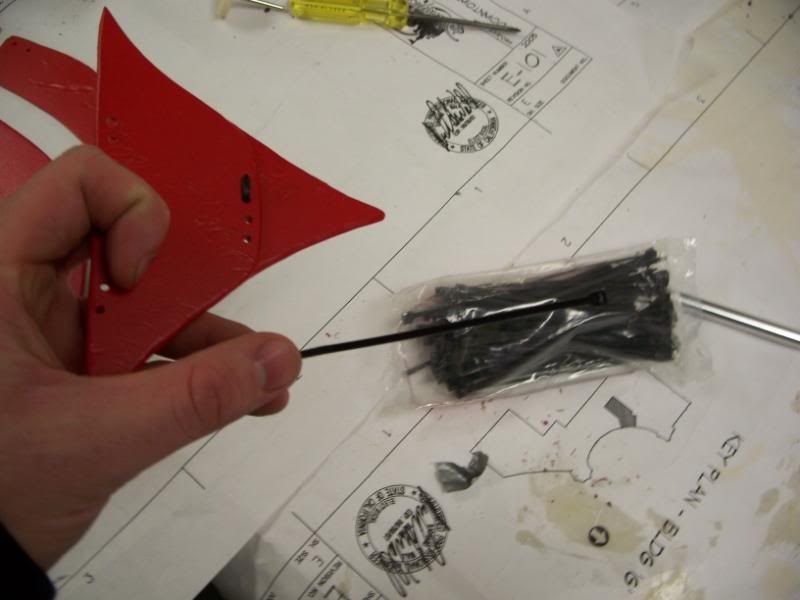

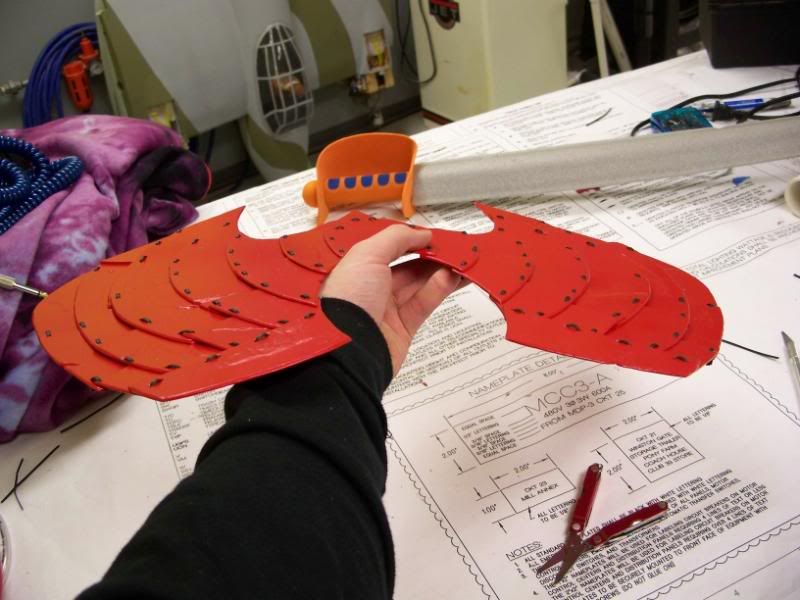

So As I went shopping at on of the many hobby shops I haunt when working on major nerf projects for sheet plastic with Falcon last weekend, it came to me. Fabrication of several small layered shingles, like samurai plate armor! It would make building it somewhat easier in some ways, and it would also be far more challenging and require much more time to do. It also quickly came to me that the best way to affix the individual parts together was not with adhesive, but small Cable Zip Ties, suddenly, there was no need for glue at all. More advantages keep popping into my head as I continued to quite vocally work on the concept with Falcon.

Reasons to go with the Samurai Armor concept:

* Small pieces makes fabrication possible when limited to the availability of smaller pieces of sheet plastic than could be used to fabricate a solid one piece manta shell.

* Individual plates can be easily re-fabricated if damaged, as removal of a broken piece and replacement could be done with little effect to the overall structure

* Zip ties give not only a strong connection, but one that flexes some, this is also attributed to the small plates

* Fabrication of such parts would make it a fairly long and arduous task, which would mean that the kind of work put into it alone makes it worth consideration for war legality

* Makes matching a size restriction, similar to the original Sicklefin more than just possible, but also adjustable.

* it naturally bends some with gravity, allowing it to have a more stock Manta-esque shape

* Durability do to superior flexibility and structural independence.

* It allows for FULL customization of the Manta Ray's look for any individual.

* when completely built, it would look really really ridiculously awesome

* Ect...

I had long been on the fence on the debate of homemade mantas, and I mainly leaned towards the side of saying "no" until I Figured out this concept. Because of the great amount of time fabrication of this takes, it shows much dedication to the hobby than just cutting out a simple one piece cardboard or plastic shield. That coupled with the difficulty of the task also keeps it from being something everyone is going to be willing to do.

As the idea became more and more feasible sounding, Falcon and I decided to lay down some guidelines for it's use in at least our wars, hopefully the rest of the community will agree with us.

1. Like a stock manta ray shell, it MUST be attached to a working Nerf blaster.

2. It must have the same opening for the hand that a stock Manta allows, leaving the user's hand exposed.(Approximately 4 inches wide)

3. Also just like a stock manta, only shots that impact the actual shield area count as deflections, anything that hits the attached blaster areas still counts like a gun hit.

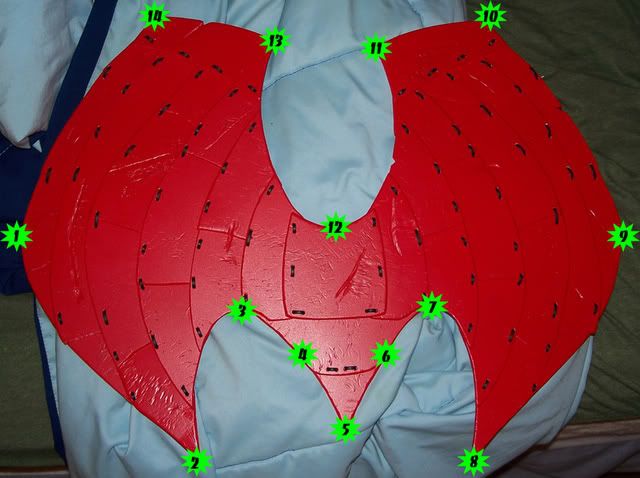

4. it's dimensions Must not Exceed a width of 20 inches and a length of 14 inches (roughly the size of the first sicklefin and my new design; which is 19 x 13.5, This also is a more reasonable shield relative to the more “adult” size of the average nerfer. I also believe that a stock manta shell flattened is about 17 inches wide, so we're talking roughly and extra 1.5 inches to the width on each side.)

5. It's generic shape must be somewhat similar to a stock manta, albeit you can have artistic flourishes. (like the extended rear fin areas I built on mine, or if one was to make one with say sawblade inspired notches)

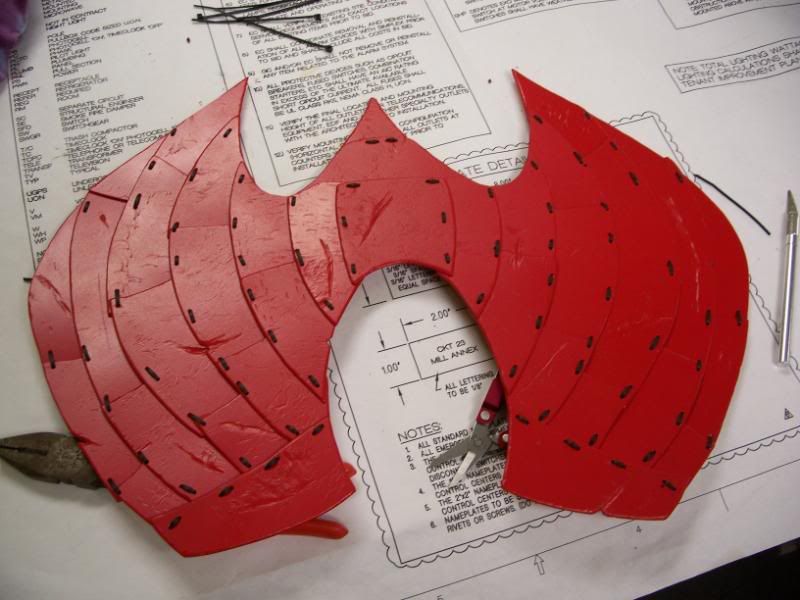

6. It mush be made of no less than 20 pieces. (mine is made of 37 pieces and has 78 zip ties)

7. It cannot be used as a way to make Nerf Body Armor, only to make a single manta-shaped shield.

8 * I'm also tempted to say that you're limited One of these per blaster, so you an put one on both sides of a magstrike or something, but I think the time it takes to produce should help keep that in check*

We also agreed that If you went to the kind of trouble I did to make one, you've earned the right to use it. This project took me roughly three days straight of non-stop work dedicated to all the steps of fabrication, so trust me it's more than a little time consuming.

So with all of this in mind, are you ready for a walk though on how to do it yourself?

Good.

How To Fabricate your own hardcore homemade manta shell:

Materials Needed:

*Sheet plastic ( I used 1/8th inch thickness hobby styrene, but most types would work just fine, I can't define the amount as It will vary depending on each shell's shape and number of pieces.)

*1 100 pack of Cable Zip Ties (approx $2.50)

*wire cutters

*Power Drill or drill press, with a bit slightly larger than the width of the cable ties

*Some method for cutting your sheet plastic ( I used a bandsaw, but there's other ways you could do it)

*Dremmel

*Sandpaper or table mounted belt sander (you could also use the dremmel)

*Sharp hobby Knife (I prefer X-acto)

Actual Process: Take note now, these are fairly rough guidelines, also, it's worth noting that this does not quite as heavily rely on precision as say, Capitan Slug's Plusbow. It's more of a Rough n' tumble fabrication process that takes patience, ingenuity, experience, and a little luck.

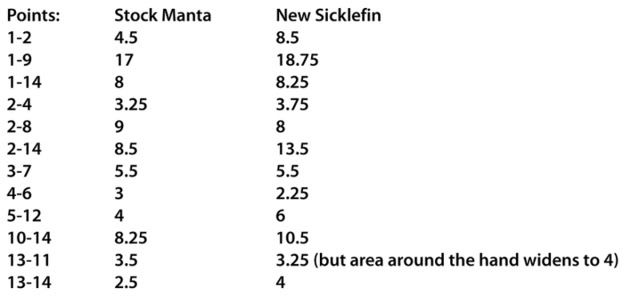

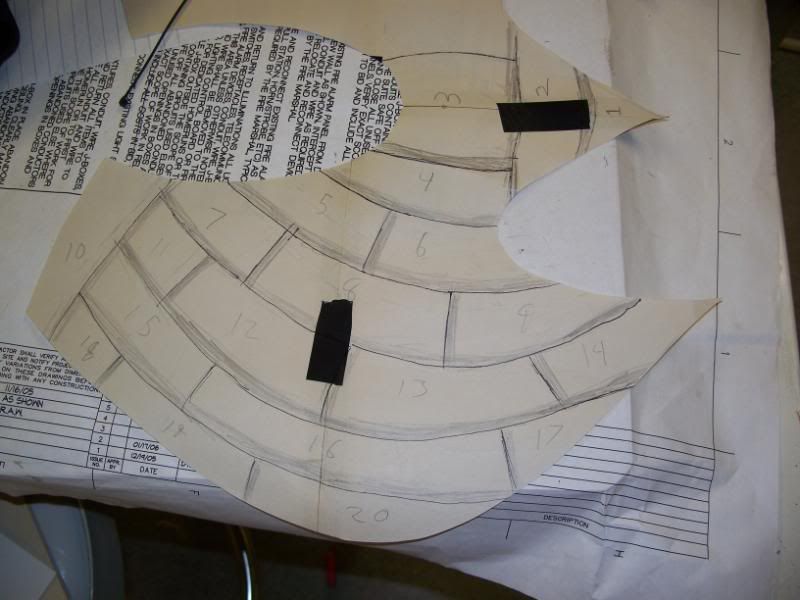

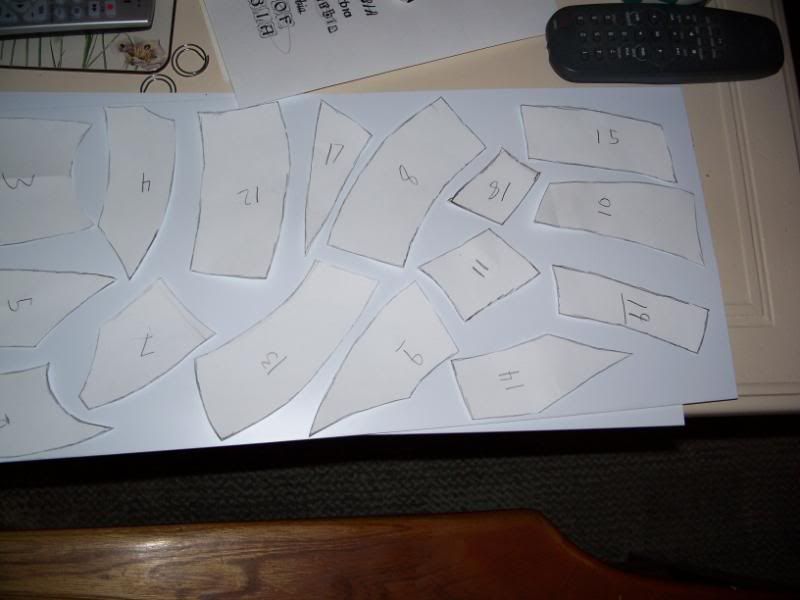

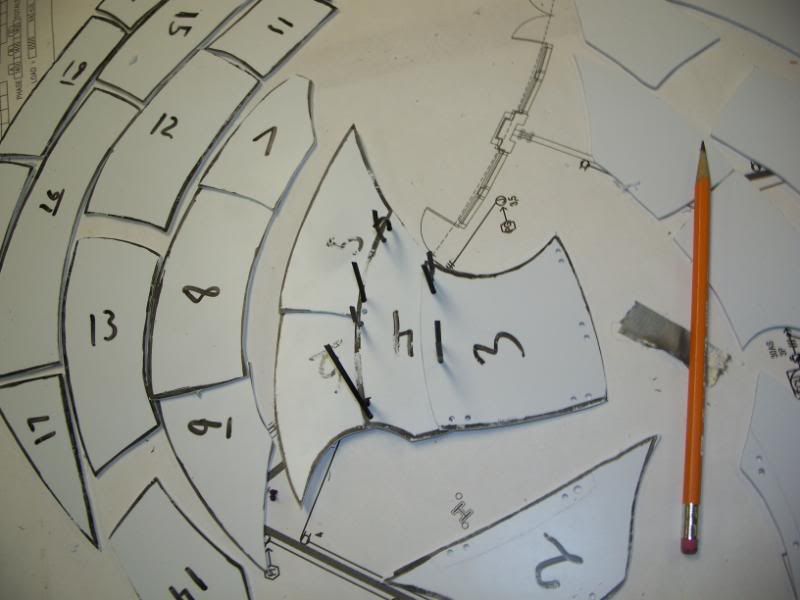

Step one: Sketch a rough outline template on paper, then cut that template out:

I made mine using a stock manta for reference, if you don't have one, just remember it's general shape and the size guidelines I mentioned earlier. I also would like to note that my template was a little larger than the final result, as overlapping parts leads to some minor downsizing.

Step two:Sketch out a fairly detailed idea of how you want to layout your pieces.

You really should only have to do this on one side of your shell template, unless you decide to make it asymmetrical, which will simply give you Much more work to do in the long run (but it could lead to some really cool looking designs). Make sure to not only define the shape of the exposed parts of the panels, but also where they will overlap. I did this by outlining the visible areas in black pen, and shading the overlapping areas gray.

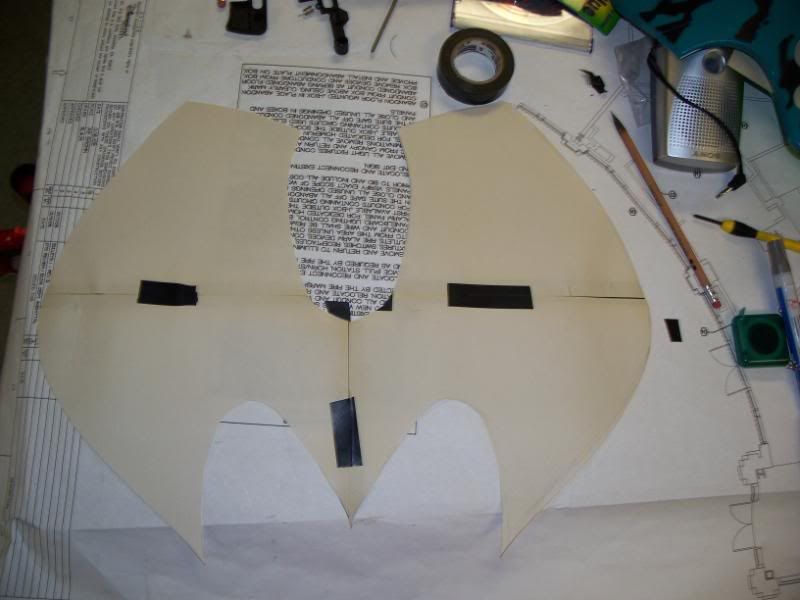

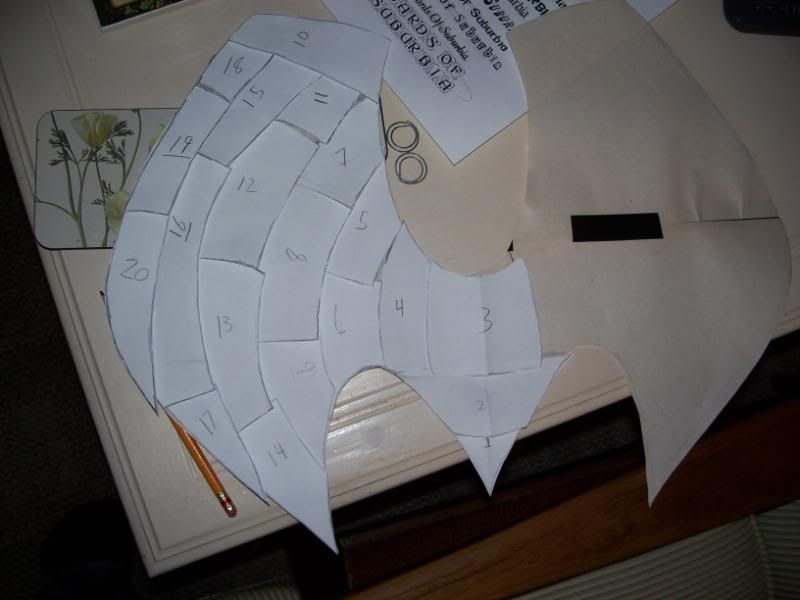

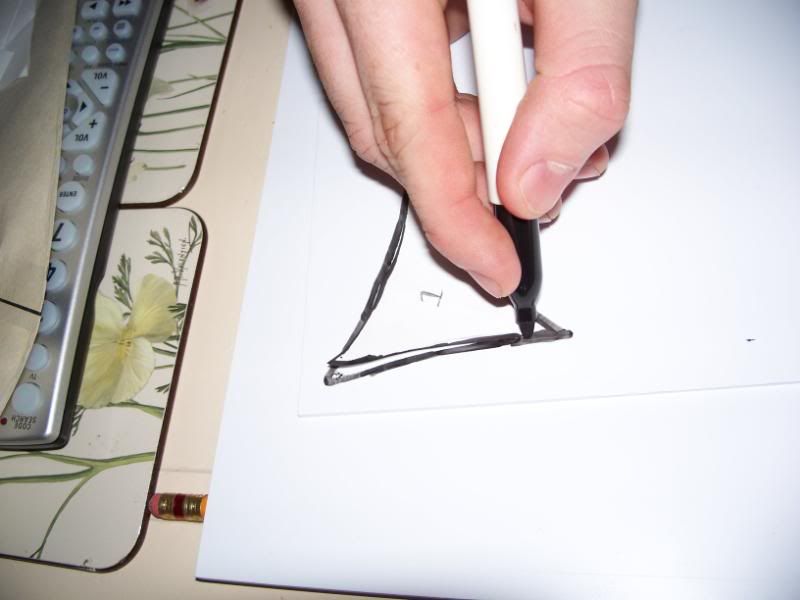

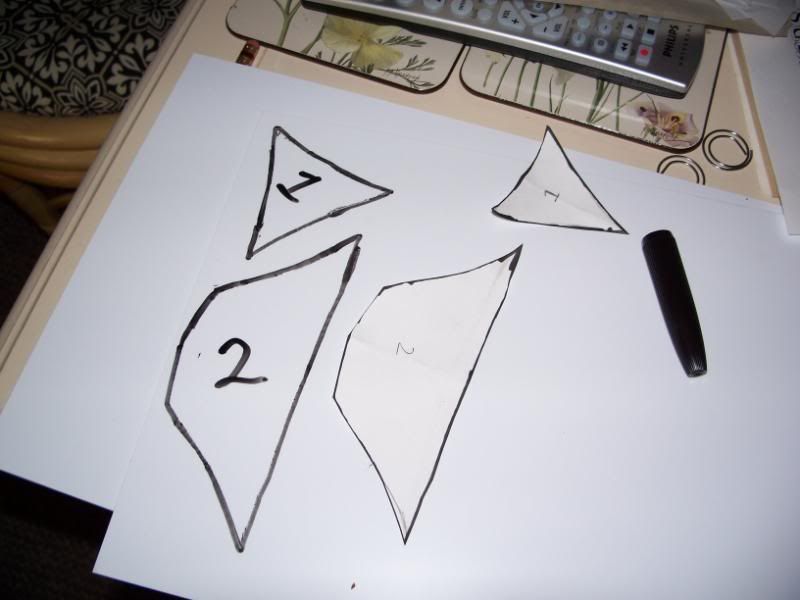

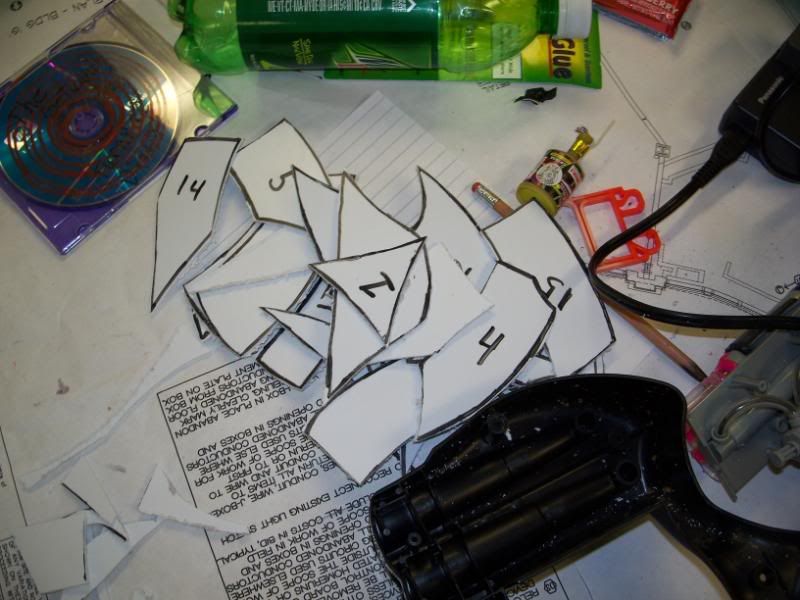

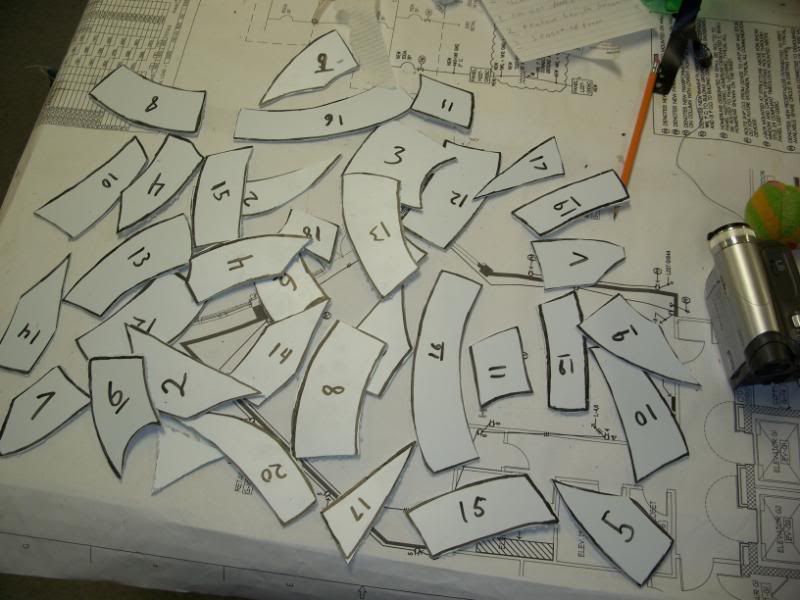

Step Three: Using your large template, Number and Draw your templates for individual pieces, then cut them out.

I did this by placing my template against a sliding glass door (it's far more accessible to most than a light table, which would also do the trick) and drawing all my unique pieces onto more paper. For overall organizational purposes Number both the individual pieces and their corresponding area on the large template. From there cut each template piece out. (If you were to do this with Clear sheet plastic, you could save yourself some time here, but you risk keeping your duplicate parts uniform becoming a bigger challenge.)

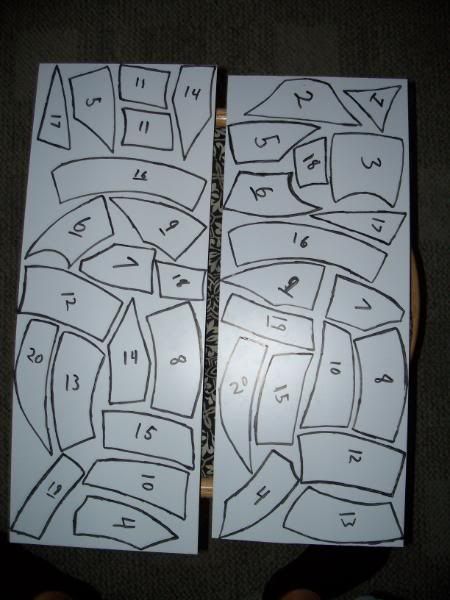

Step Four: Plan out your use of the sheet plastic.

Using the new templates I drew outlines of all my parts on my plastic sheets. Making sure to have all of the unique parts, as well as all the duplicates. This is part of why the numbering comes in handy, you can check that you have all your needed parts before you start cutting things to bits. You don't need to flip your parts for the opposite side while you're drawing your cutting guidelines, you can just flip them over after you've cut them out.

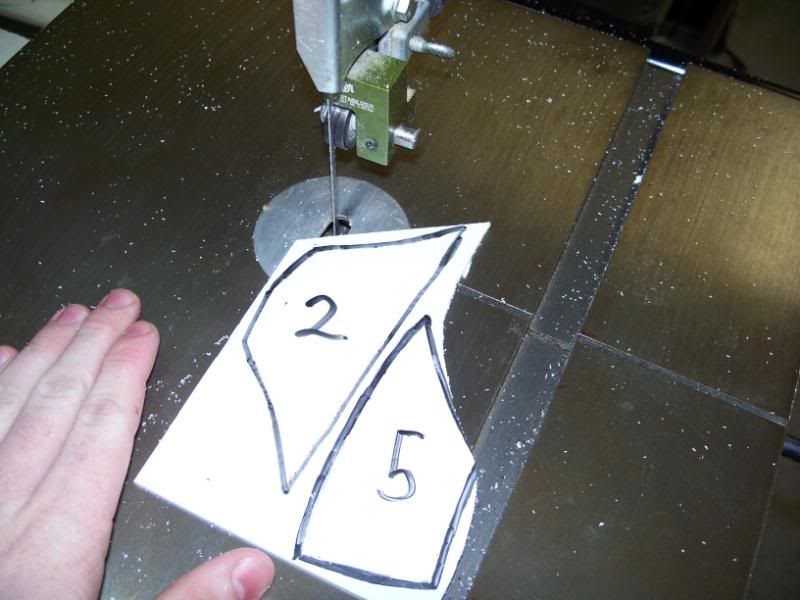

Step Five: Cut out and clean up your pieces

This is possibly the least challenging part of the whole process, because all you have to do is cut along your lines well. Then from there take your finished pieces and sand the outside edges, this will clean things up some, I also highly recommend that you do some minor adjustments to make sure the mirrored pieces are fairly close in size. Scrape around the edges with an x-acto knife to help remove any excess that wasn't removed via sanding.

(image limit)

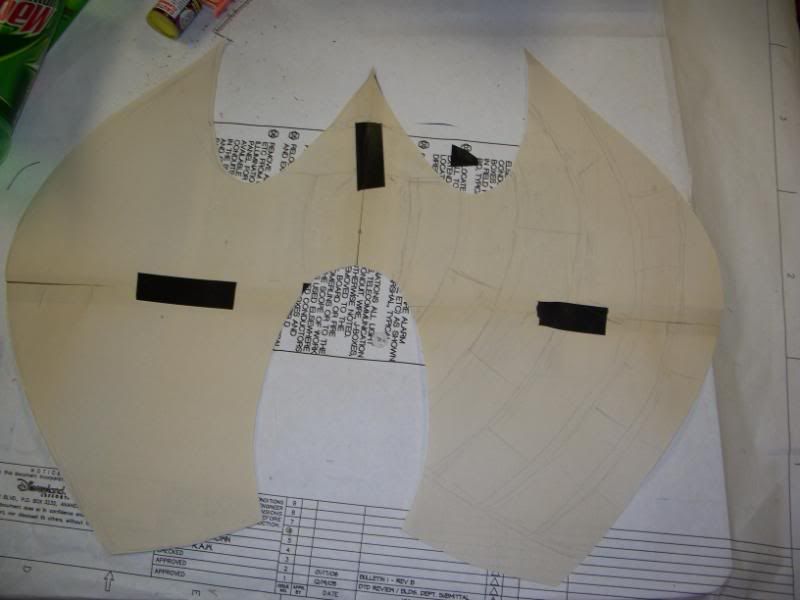

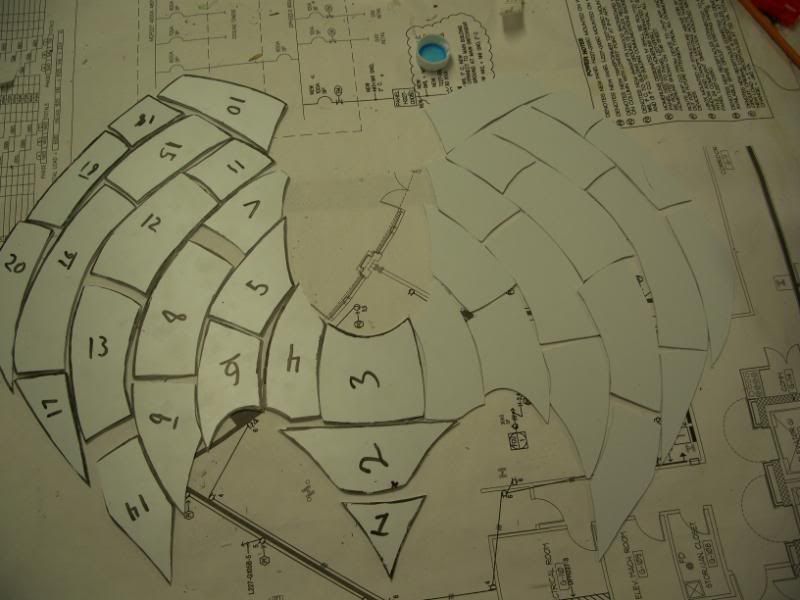

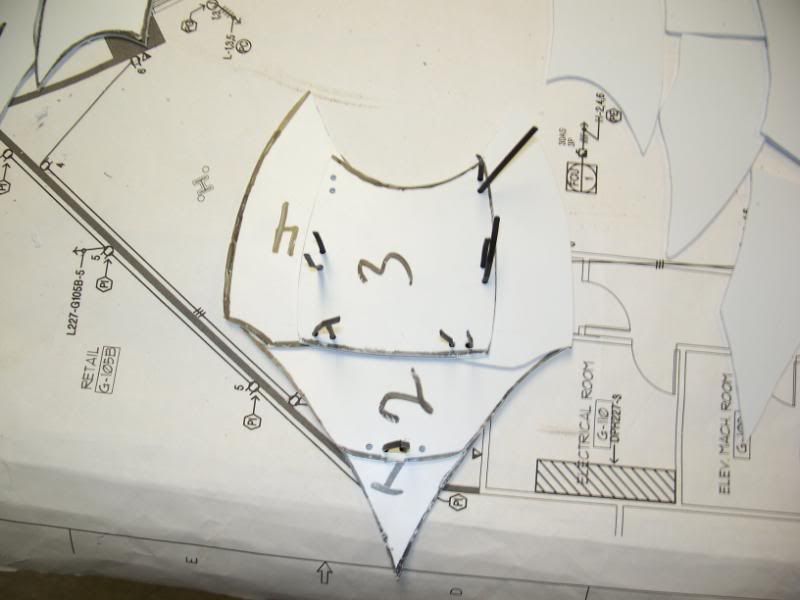

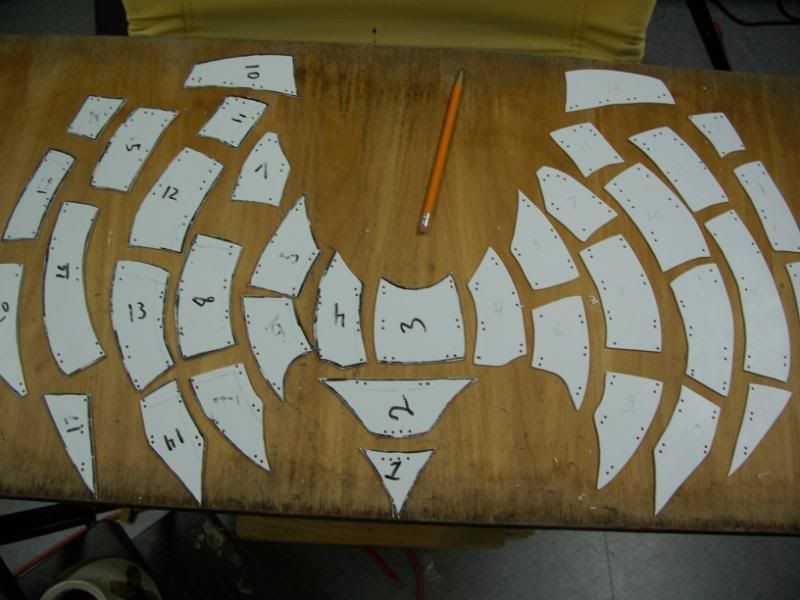

Step Six: Lay out your Parts

This is actually a curtail step, and where this goes from cool idea to sadistic nerf puzzle, This is why I suggested numbering both the complete template and the individual parts. Make sure you have the workspace to Keep these parts laid out like this for the rest of your project, as it will help keep things organized as this gets to the more intense parts. You also may once again want to test out how everything is going to overlap during this phase.

Step seven: Drilling Holes

This is possibly the most complicated and challenging part of the whole process, but it really is one big step, even though it can be broken down into smaller parts. As it only gets harder as it goes, I suggest fully building one whole side of the shell first, after that, you can simply drill duplicate holes on the opposite side. This however is not a prefect process and you may have to do some minor tweaks along the way. Don't worry, that's just how it goes. If you've decided to make an Asymmetrical design, you'll have to make unique holes for every part.

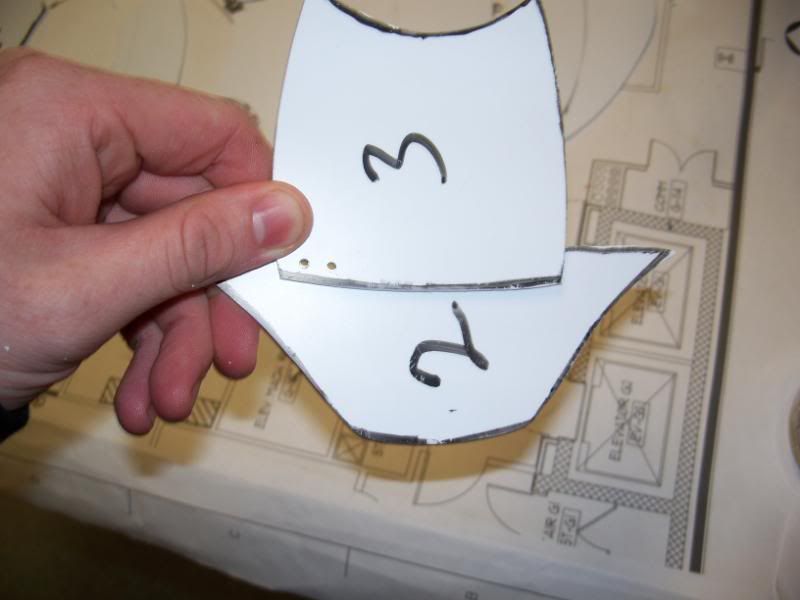

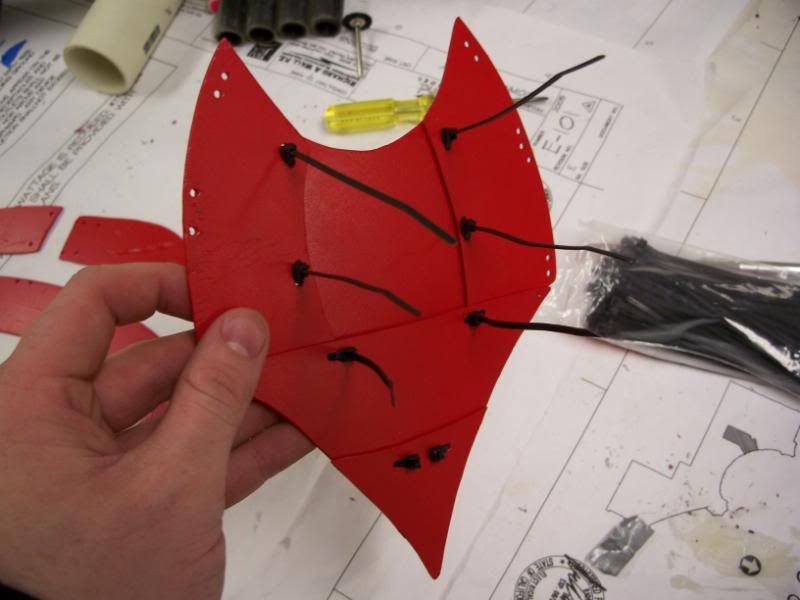

Anyway, You need to line up the parts How you want them to overlap, and then drill the required holes. Each Zip tie takes two holes, and you should have at least two zip ties holding a piece to another. Also, your holes should be drilled about 1/8 -1/4 of an inch from the outside edges of your parts, this will keep them from breaking off easily. In some cases, it is not a bad idea to actually have a hole that runs through three pieces rather than just two.

As this is going along, you may want to make sure everything is lining up overall, so I suggest either sacrificing a few zip ties for this stage, or threading something else through the holes.

As you get to the outer edges of your shell, you may find that it's hard to keep things all lined up unless you try to do it all at once. You can keep a whole level of panels together with duct tape while you drill your holes.

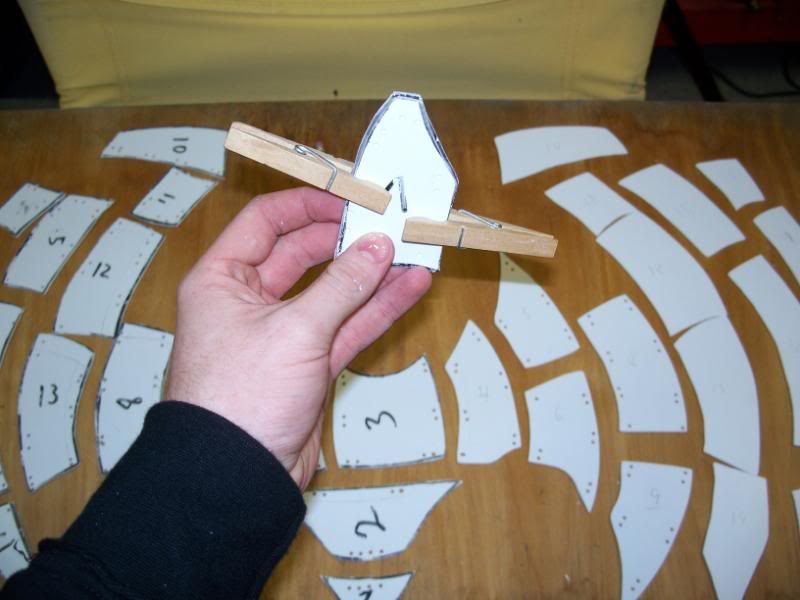

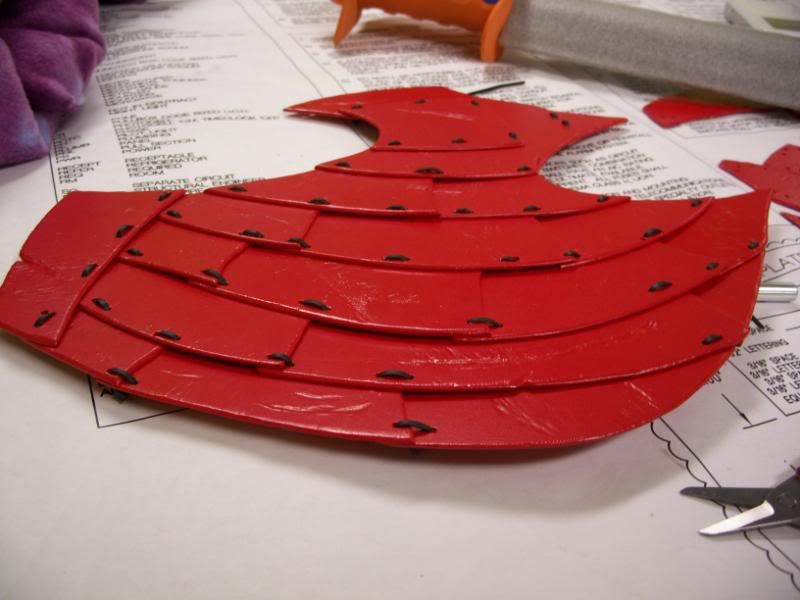

After you've made one half of the shell completely, you can line up your other halves and drill through the holes you already made, to help drill them all cleanly you can clamp the two matching parts together with clothespins or small clamps.

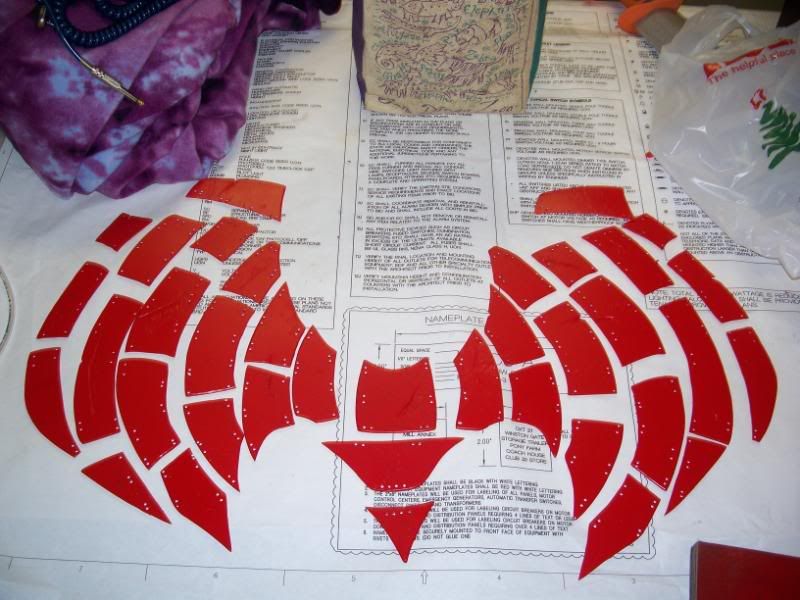

Step Eight: Further cleanup: Smoothing, Weathering, and painting.

(I don't have pictures of the weathering process as I had to recharge my camera's batteries while I was doing that part of the work, there are pics of after I painted though)

The Bulk of this step is all personal choice, I wanted my particular shell look more like leather samurai armor, I achieved this by softly sanding all the faces as well as doing intentional damage with my dremmel's wire brush attachment. Be wary of where all your holes are, and make sure you don't break any of them open. It is also important to take note, that If you plan on putting a notch into the edge of one piece, for overall effect you should continue the cut into the piece that notch overlaps. After the sanding you can clean up all your edges with an x-acto knife. I then Painted the parts with red Vinyl Dye, which adheres to all the small little scratches rather than filing them in.

Step Nine: Assembly.

This part really isn't very difficult if you've been diligent in doing all the other steps, it's just lots of lining up pieces and threading zip ties through. Once you zip down a zip tie, cut the extending tail off. As you go along, you may find that some parts don't quite line up as you hoped, or overlapping areas cause problems, don't worry. Just cut off intruding overlap and don't be afraid to drill a couple new holes. It's all part of the process. Eventually you should have something that looks a lot like a manta ray shell in your hands! Be proud of your hard work, it was well worth it. The underside of the shell may not be to comfy, as the clipped off zip ties are rather sharp. I plan on putting a layer of foam craft sheet on the exposed underside of mine when the time comes to actually put this to use.

Step Ten: Mounting

I personally haven't gotten to this step yet, but I would say that it's really up to you and what you plan to use your shell for. I will be putting this on the top of a stock manta base shell that's had a pair of splitfires integrated into it. And As I don't know what is going where exactly just yet, I can't point this stage out in detail, and even if I did, it would only be beneficial if you were trying to attach it to a stock manta lower shell that's had splitfires integrated into it. I would suggest mounting it similarly to how The Plusbow is held together, with adjustable hardware rather than with any form of glue. As that would lead to issues in being able to cleanly remove/repair/replace damaged parts.

And with That the How To part is covered.

I hope this in-depth look into a possible way to make a detailed homemade manta style shell becomes considered a viable way to have one that is war legal amongst the community. The Amount of time and effort put into it alone should be a strong enough case, and when coupled with making one within the earlier mentioned guidelines, could really be an excellent way to keep the single legal nerf shield available to those who can't find one or want a more “unique” one, and happen to have a lot of time on their hands. I'm sure someone like Capitan Slug, or one of our other diligent members who has more patience and experience with CAD than I could draw up a slick digital template. But I liked taking a complete hands on approach, I'm just that kind of a fabricator.

Overall cost for this was about 20 bucks, so as rarity grows, it may become a very cost effective way to have a manta. Don't forget this took me almost three whole days(like over 12 hours per day kind of whole) of straight work to make, and that was accelerated by me having access to my grandpa's workshop of powertools, doing this by hand with a dremmel or even just hand sanding would greatly increase the time taken to build one, but it is still completely possible. Also, this idea is not limited to using sheet plastic, although, most other materials would either not be durable enough, too heavy, or too costly.

So... Questions, Comments, Complaints, Suggestions, Ect?

-Bags

Edited by Aeromech, 23 November 2015 - 03:15 AM.