For the lazy, here’s a TL:DR. If you’re having problems with a clothespin trigger, the hole in the plunger tube is probably too big.

For the reasons why, read on.

First, some explanations about how it works, and what the parts do, starting with that most visible part.

First things first: the clothespin does absolutely no work in resisting the force of the plunger spring. I’ve heard some comments from people about how their clothespin is “too wimpy” and how it can’t stand up to the force of the spring, or seen SNAPs with rubber bands around the clothespin to keep it shut. Both are symptoms of the same problem….and the only reason to put a rubber band on a CPT is if you like a stiffer trigger pull.

The clothespin serves as a lever with a return spring to lift the nail, and then put it back in place: that’s all. The work of resisting the plunger spring is done by the nail and the hole.

(A note about the hole in the clothespin: that actually needs to be a fair bit larger than the nail. We want the nail to slide straight up and down in the hole, but the clothespin moves on a pivot. Since its motion is circular, the hole needs to be bigger to allow for a bit of wiggle. After all, the clothespin is just lifting the nail. The spring is putting the nail back into place. All that can be done by the nail head, and doesn't need any contact on the shaft of the nail...so make the hole in the clothespin loose.)

For all practical purposes, a plunger spring cannot shear through metal. That’s why most any nail works in a SNAP trigger. The most important part is that the nail is only able to move straight up and down, and not tilt. This is why a snug hole is so important: the thickness of the PVC is what keeps the nail straight against the force of the spring (and is also why thinwall PVC doesn't work well with CPTs). The catchface ramp will also work most efficiently if the nail is straight up and down, with no tilt. If the nail is able to wiggle at all, then the clothespin has to start fighting against the strength of the plunger spring, and the motion of the plunger….and this is where diagrams come in handy.

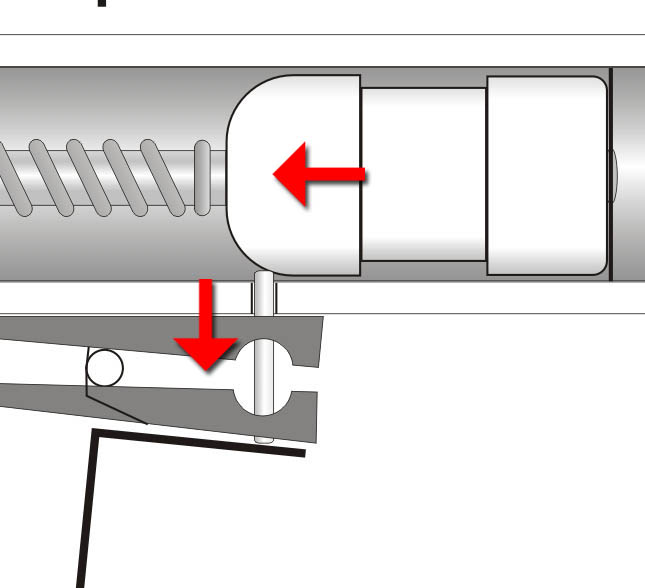

Standard CPT: the plunger moves back, causing the ramp on the rear of the plunger head to push the nail straight down.

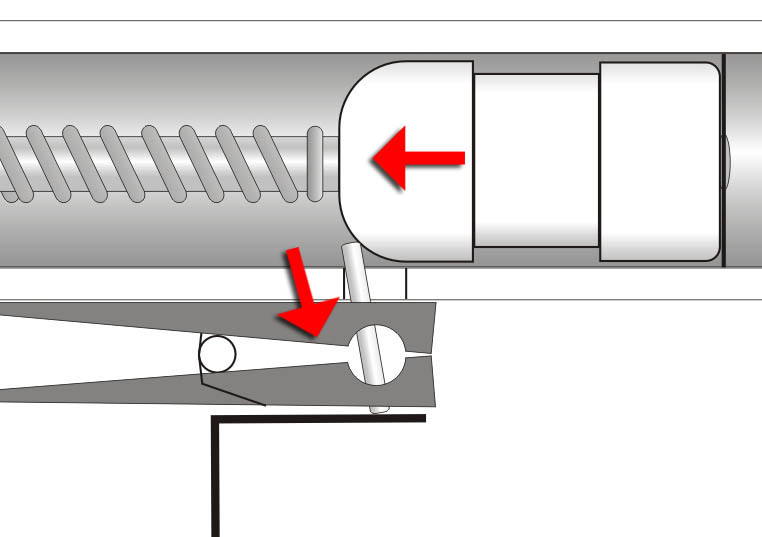

But what if the hole is too big? (Only a slight exaggeration of scale here, I've seen some SNAPs with nail holes this big...)

If the nail rocks back at all, then the direction it has to move becomes down and slightly forward...which means the nail is starting to fight against the plunger motion/direction. This also causes the nail to bind up in the hole.

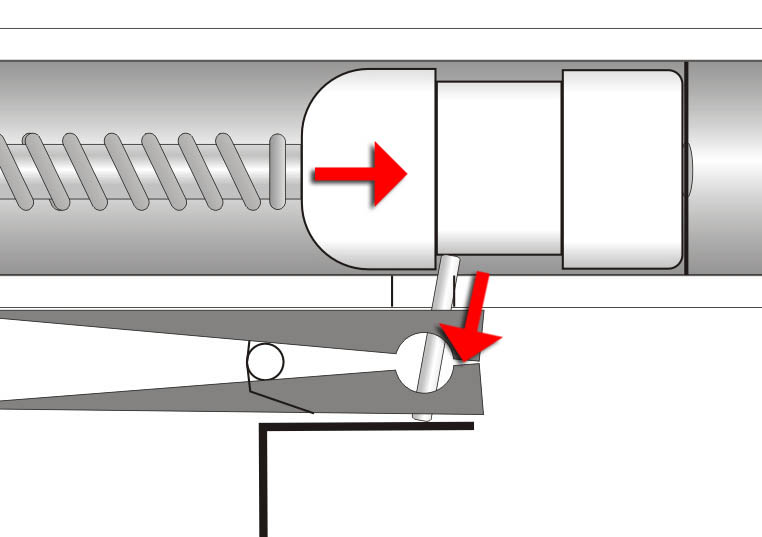

If you manage to cock it, there are problems in the other direction:

The plunger is being held in place by an angled surface, rather than a straight up-and-down pin, so there's reduced surface area actually holding the plunger back. The nail itself is acting like a ramp, and helping the plunger head slide past it. This is why additional rubber bands are often needed to keep the clothespin shut: it's not that the clothespin spring is too weak, it's that the hole is too big.

So how snug should the hole be? he nail should be able to slide up and down without too much force, but not easily drop all the way in. After all, the clothespin is there to push the nail back in, so it doesn't matter if it sticks a little bit.

Edited by Carbon, 23 February 2015 - 11:36 AM.