This mod makes the Hornet so powerful that you may need a new pair or pants after you read this post. But first, a cartooned warning and the possible use of such a weapon,

You have been warned. And now, the final product:

What you will need.

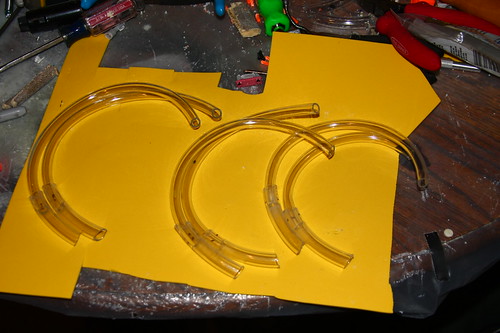

-1/2" and 1/4" clear vinyl tubing (make sure the little one fits snugly into the big one)

-1/4" CPVC and 1/2" PVC

-1/2" PVC cap

-Glue

-Wire cutter or scissors

-3/4" drill bit

Remove the ARs from the Hornet.

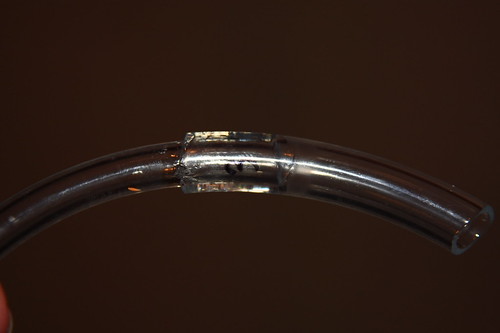

Lets start with the tubing. Stick the larger tubing into the hornet barrels and cut them off so that about a half an inch sticks out the ends. Then cut some of the smaller tubing so that it can go from the barrel to the top of the hornet with some slack. The bottom ones should be longer than the tops. Put some glue into the large tubes and slide the little ones in. You may want to go all the way down so that the inside of the bigger tube is filled completely with the little ones for a better seal (in retrospect).

Next, grab a shell and cut the back end off. Then pull all of the ARs out.

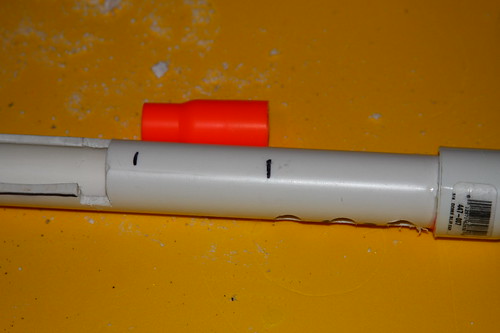

Then grab your 1/2" PVC and drill 6 holes on one end and cap the end (and glue the cap on for good measure).

We are cutting out a breech like I did in my Singled Doubleshot mod.

Mark a space for your shell and cut the breech just a 1/4" or so ahead of it. Make sure that when you cut the breech, the holes that you drilled are horizontal, not vertical. Like so:

Then you need to go to the Hornet itself. Tear the top part off (or unscrew it if you want to) where you prime the gun before you pump it and cut the top hump off the hornet.

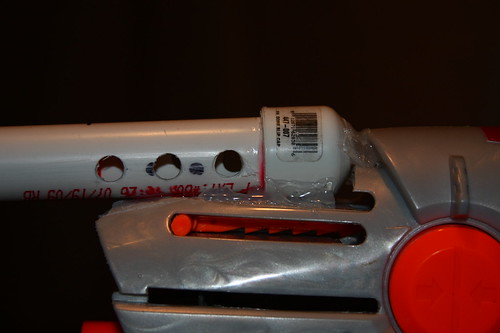

Then glue your barrel on any way you can. I used copious amounts of hot glue and some super glue on a few parts.

It's actually a lot more stable than it looks.

From here you just need to put the tubes into the barrels and connect them to the holes in the PVC barrel.

From above:

Saw down your PVC and put a CPVC barrel in and you are done!

I have not been able to get an accurate range yet as it is almost 1AM, but I fired it once inside and the dart cleared 60', hit the wall and bounced back to just 10' in front of me. I would conservatively guess right now and say it will shoot a black whistling dart at least 200' if not more. I will try it tomorrow and let you know.

This is clearly a very long range weapon, as close range with this would be painful and it takes minute to fully pump (though if you figured a way to do an air compressor mod on it, you would be an unstoppable machine).

Just make sure you keep it away from my cat...

Find content

Find content