I'm going to pretend you didn't say that. I will now go and cry about my inadequacy in the corner. JK but seriously, how did you do that? Does it seal well?

Very very well.

I was studying how high power air rifles work.

Although most modern air rifles use a sort of expensive silcone seal, back in our grandfathers day they used leather seals.

And it turns out that making leather seals is rather very easy.

You need natural undyed vegtan leather. This is very important as this leather can be molded by using warm, but not boiling, water. Hot tap warm I find work well enough.

The leather should be about 1.5mm to 2mm (sorry about metric measurements, I'm from the UK)

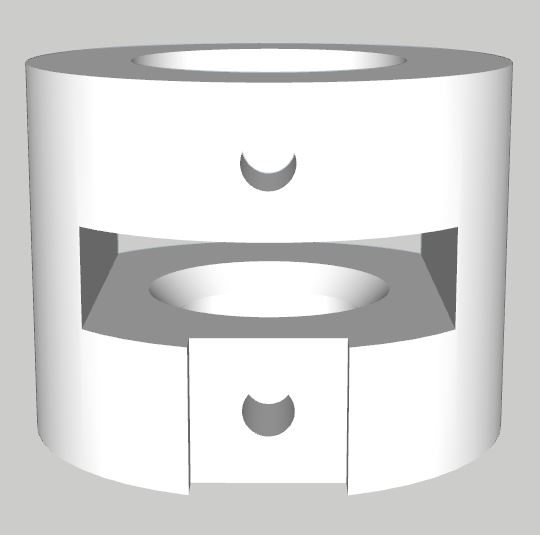

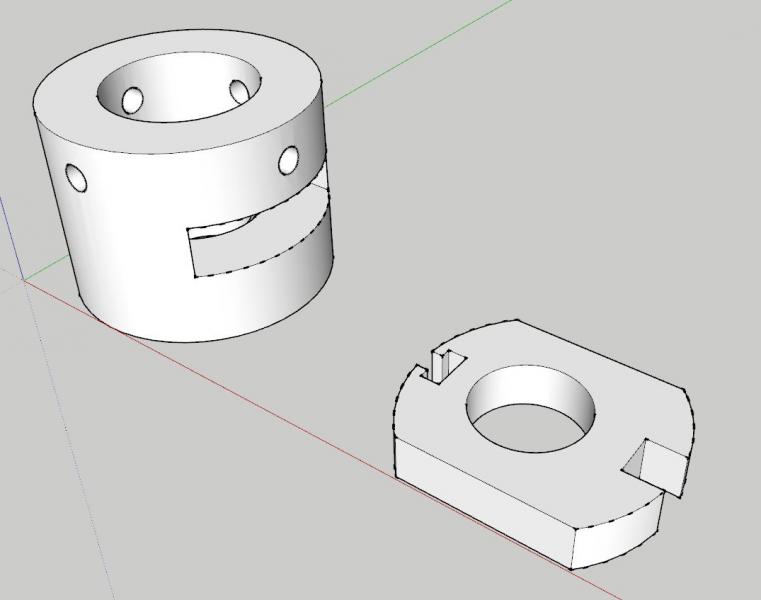

Next you need to make a mold. The sides of the mold should be the same internal diameter of your compression chamber (thats the Air rifle term for the air chamber)

Personally I just create one from a 12-15mm (or 1/2 inch) tall piece of the tube I use for the actual compression chamber.

Next you need the ram for the press, this should be around 3-4mm smaller in diameter than the ID of the compression chamber.

(don't worry I'll link to some sites about how to make these at the end of this post)

With the pieces of the mould made, you'll need a clamp, I find big woodworking hold down clamps work a treat.

Cut a piece of leather thats big enough to fit over the mold. Wet your piece of leather in the warm water until it more or less stops bubbling.

Place it rough side out, over the ring of the mold, and place the ram on top, transfer this to the clamp, and force the ram right into the mould.

Take a nice sharp knife, and trim the excess off.

Next leave it to dry for about a day. (I find overnight works)

Take it out the clamp, soak it in a couple of drops of oil (leather likes to be oiled in order to be supple, and you can get good oils for this) , and presto a cup seal that is pretty match for a rubber seal, but more interestingly is self lubricating.

This video most closely resembles how I make mine, except I don't use the screw method, and use woodworking clamps instead.

(some of these sites recommend using a socket as the ram, not tried that myself, as I made mine on my lathe, but I bet it would work)

http://www.pyramydai...er-piston-seal/

http://www.network54...er piston seals

Find content

Find content

Posted by

Posted by