Amazing work, earlier this year I drew plans to make something like this, but the feeding system was not as reliable. Also instead of firing one dart at a time I pleaded to have a 3 in feeding ramp to use streamlines or 2 Steffens at a time to have a " shotgun" effect, but all in all this awesome.

This design could easily be adapted to use shells to shoot 3-darts at a time.

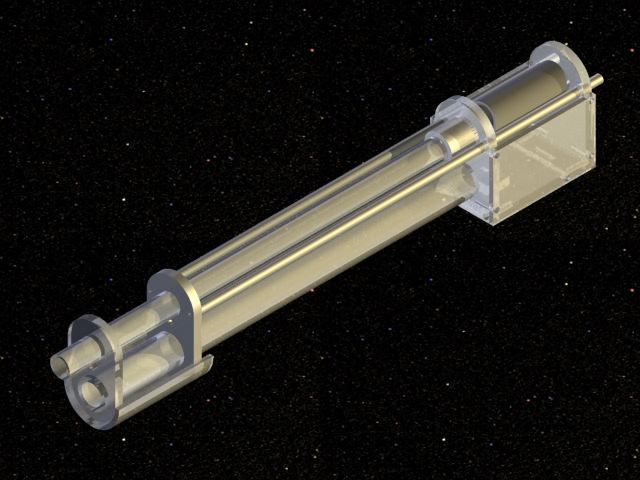

Because I truly have nothing better to do over the summer, I decided to create a 3d model of a version of this, specifically made to drop in to a revshot with little modification. At least, one of my revshot designs. It comes with internal aluminum priming bars that connect directly to the plunger tube and a kind of ugly fore grip. Pretty rough right now for the internals, but is mostly complete. i just have to complete the dart loading ramp components and make it look sexy.

It won't really be bronze tinted and photographed in space, but it made most of the components relatively visible. You can't appreciate a 3d model in a picture.

That looks amazing! I'm looking forward to seeing the final product.

Find content

Find content