Firstly, for your questions:

1) I don't remember, really. I do know that I did not have access to an electric drill at the time (I believe I was 9-11 years old), so I used a hobby knife to cut a circle-esque shape in the front. If you used a drill I think you should be okay going up to some large sizes. Just leave enough meat around the front to withstand some hits. If you're going to replace the spring, I'd suggest you reinforce the front tube somehow because that is effectively the plunger-stop. I used two metal wires (I removed one because it was unnecessary and air-restricting) through a 1/2" PVC coupler epoxied onto the front of the gun as a plunger-stop now.

2) The clamp I am not sure of either. Something fairly small--probably the smallest clamp you can get ahold of. The clamp isn't really necessary--just something for support.

Some other things you might want to know:

The dowel should be longer than the one you see on mine. I took the Rattler nerfing and I always pulled fairly hard on the cluster of barrels and it ended up falling off the dowel a lot of times. Instead, have a longer dowel so you can pull it farther from the gun without it coming off. More travel room is good.

The piping/tubing you use to bridge the CPVC from the air source (gun) to the cluster of barrels is really up to you. I have no standard solution to doing this... so just find something that fits well. I've taken my own advice and used the thick widebody pen as the pipe diameter. I used the rubber grip to seal onto the CPVC barrels as well.

The addendum is just a spring replacement and an improvement of seal between the gun and the barrel clusters (above).

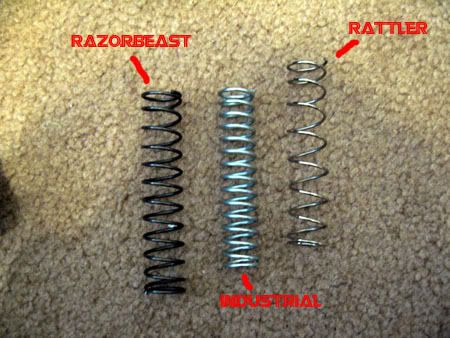

The industrial spring is:

3 1/8" Length

11/16" Outer Diameter

.080 Wire Gauge

and found at ACE Hardware.

The new ranges from before:

Rattler unit: 59 feet (average)

Triple Torch unit: 45 feet (average--the same as before)

EDIT: Why can I never spell Triple Torch correctly on the first try?!

Edited by frost vectron, 28 May 2007 - 10:53 PM.