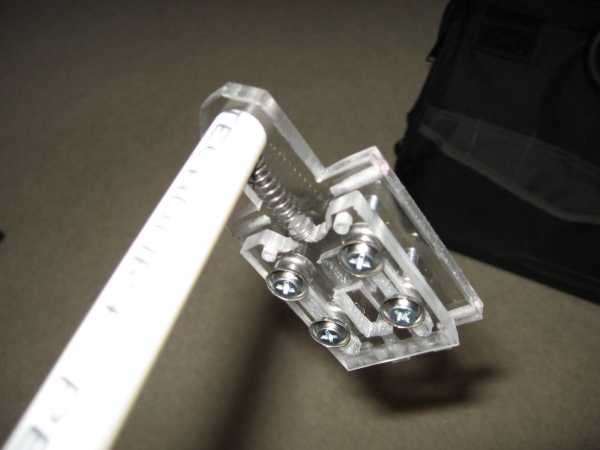

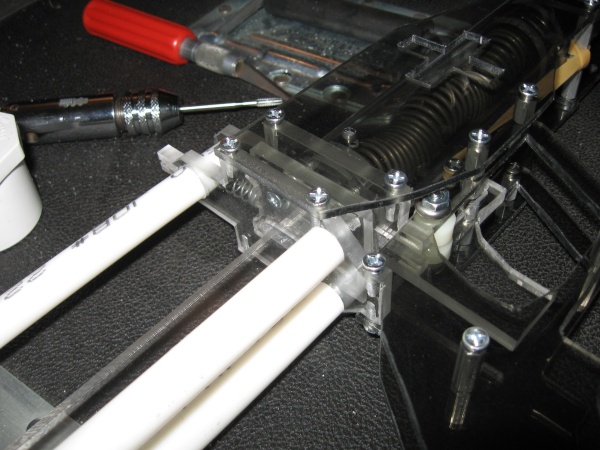

The metal piece is called an angle iron. It's in the metal fittings isle (next to hinges, maybe doorknobs... small metal attachments). They usually come in sets of four, I think the size I use is 3/4" and about $2.50 a pack.

Alternatively, you can use Hex Keys, they could be anywhere -- just ask. Any size will do; too small and you get less leverage, too big and it looks... too big. They're generally $0.25-0.75 depending on the size you get.

Whatever you use, zip tie it in place and hot glue around the edges. Put the angle in your piece closer to the coil of the spring on the clothespin for better leverage.

- - -

EDIT: Double posted. Kinda. For whatever reason. Anyways it's fixed. : o)

Edited by Flaming Hilt, 21 July 2007 - 08:18 PM.

This topic is locked

This topic is locked