Still, don't fail a 36 page paper in the name of nerf... That's just retarded. And if you are doing 36 page papers AND making this thing, don't worry about it on your vacation... it seems well deserved.

#101

Posted 16 April 2006 - 05:49 PM

Still, don't fail a 36 page paper in the name of nerf... That's just retarded. And if you are doing 36 page papers AND making this thing, don't worry about it on your vacation... it seems well deserved.

#102

Posted 18 April 2006 - 08:20 PM

I manually test-fired one of the barrels with brass inserts while in the basement this afternoon and the dart shot all the way across the basement, deflected off the partly-opened door on the other side and disappeared into the storage room. So the 50-foot mark looks to be more than blown. I can do more manual testing once I get back from my trip and can get the breech holes cut, but it's no real suprise that I'm getting performance similar to what Carbon has been getting with the Snap model I based the essentials of this gun on. My setup only differs in that I'm using a longer spring.

Edited by CaptainSlug, 03 May 2006 - 07:03 AM.

#103

Posted 18 April 2006 - 11:57 PM

You do relize that when you create something as good as this by law you have to make a detailed write-up. Ok i lied but you better!!!!!!

Good luck with the testing and hope you manage to find some time to finish it in the near future.

Have you ever thought about making an attachment so that it can be mounted and then put in on servers so its remote? I know there was some talk about this at the begining of the thread but just curious to see if you would. Because with mine i made a stand to be used as a turret but as mentioned at the begining of the thread the gun is no more.

#104

Posted 19 April 2006 - 12:00 AM

#105

Posted 19 April 2006 - 12:04 AM

Well i still stand by my other comments. Do you actually plan on making a write-up and if so would it be in exel like bolt did so the majority of people can get it?

#106

Posted 19 April 2006 - 12:10 AM

Edited by CaptainSlug, 19 April 2006 - 12:10 AM.

#107

Posted 20 April 2006 - 11:37 AM

I eagerly await further news of this incredible project.

Good luck in school!

#108

Posted 02 May 2006 - 10:59 PM

And for those wondering YES I will be making detailed machining and assembly instructions/plans. But only after the gun is made and working.

Edited by CaptainSlug, 03 May 2006 - 07:04 AM.

#109

Posted 04 May 2006 - 05:17 PM

I'd do more today but my hands really hurt from all the cutting work. Plus I cut two of them...

Next I need to make the breech actuating sleeve and the actuating shoes and tracks for the plungers. Then I can move on to the outer shell.

Once I can get to the store and buy some loctite clear epoxy I can test the dry-firing to get a preview of the ranges. It's already looking very good but I'm anxious to see what it gets.

Edited by CaptainSlug, 05 May 2006 - 12:20 AM.

#110

Posted 05 May 2006 - 12:08 AM

Nice. Keep up the good work!

#111

Posted 06 May 2006 - 09:09 PM

And out of dumb luck I discovered that if I make the breech track so that the breech is closed when the dart is picked up, then there is only enough space for a single dart to be grabbed. The breech will open as soon as access from the dart hopper is closed off. I may want to modify the advancing teeth to accomodate this change.

And I sanded the text off of the barrels.

More to come next week.

Edited by CaptainSlug, 06 May 2006 - 09:22 PM.

#112

Posted 08 May 2006 - 10:46 PM

-bags

Edited by baghead, 08 May 2006 - 10:46 PM.

Don't call it a comeback, I never left.

#113

Posted 08 May 2006 - 11:40 PM

Edited by CaptainSlug, 08 May 2006 - 11:40 PM.

#114

Posted 10 May 2006 - 05:20 PM

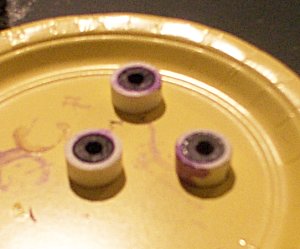

I did however find a use for the brass I couldn't do anything else with...

Edited by CaptainSlug, 10 May 2006 - 05:20 PM.

#115

Posted 13 May 2006 - 08:58 AM

#116

Posted 13 May 2006 - 09:58 AM

~ompa

#117

Posted 13 May 2006 - 11:41 AM

Edited by CaptainSlug, 13 May 2006 - 11:46 AM.

#118

Posted 15 May 2006 - 03:27 PM

#119

Posted 24 May 2006 - 04:30 PM

P.s. I will personally s*** myself if that gun works.

Account Suspension Notification

[DYE]Terminator[gen],

Your member account at NerfHaven has been temporarily suspended because I don't like you. Shindig doesn't like you either. You watch yourself, we're wanted men. I have the death sentence on 12 systems.

Talio---

#120

Posted 06 June 2006 - 08:12 PM

Meanwhile I'm busy working on my computer case/watercooling project.

#121

Posted 06 June 2006 - 08:31 PM

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#122

Posted 06 June 2006 - 09:06 PM

He cleared it out a few months ago on ebay.What about Vipers petg? He might still be selling it.

Don't call it a comeback, I never left.

#123

Posted 10 June 2006 - 08:52 PM

Now you know that thing on how machine guns and the gattling gun work, would the plungers act similarly like the firing pins in the animated diagram of the gattling gun in action? That's pretty cool. No cocking or pumping required

Edited by SG Pilot, 10 June 2006 - 09:01 PM.

#124

Posted 11 June 2006 - 10:54 AM

#125

Posted 11 June 2006 - 01:12 PM

The only parts potentially touching the inside of the 4" PVC shell would be the smooth-milled polycarbonate frame pieces. The internals will be suspended inside the shell, attached tothe center axle. So friction concerns will only be relevant to the advancing tracks that actuate the breeches and the plungers.Yeah, that would be cool. A full auto nerf gatling... But what if the endcaps produce a lot of friction and damage the internals?

I may have to just knuckle down and lathe my own barrels. I really didn't want to have to because the drill bit required to do so is kind of pricey.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked