Question for tulip: would/does the current iteration of the design work with 16,25,and 35 dart drums?

Hello Silly, to be fully honest, I couldn't confirm that to be the case, as Stacy was designed to work with a standard nerf Magazine. If drums have the same external dimensions for their connection and dart retention clips, then there shouldn't be any issue with using one.

Thanks to Mr. Jwasko, Mr. Meaker and Cpt. Slug's suggestions and comments, I've made some significant changes to the design again, and this time I think I may have a winner, though I am, as always, very open to suggestions.

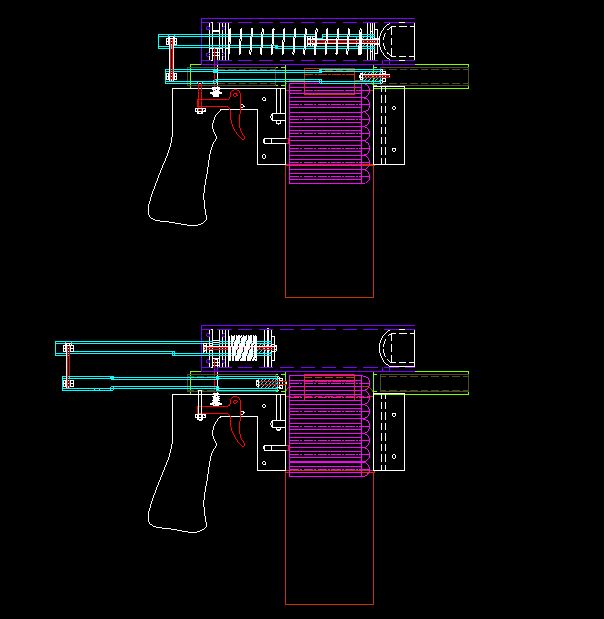

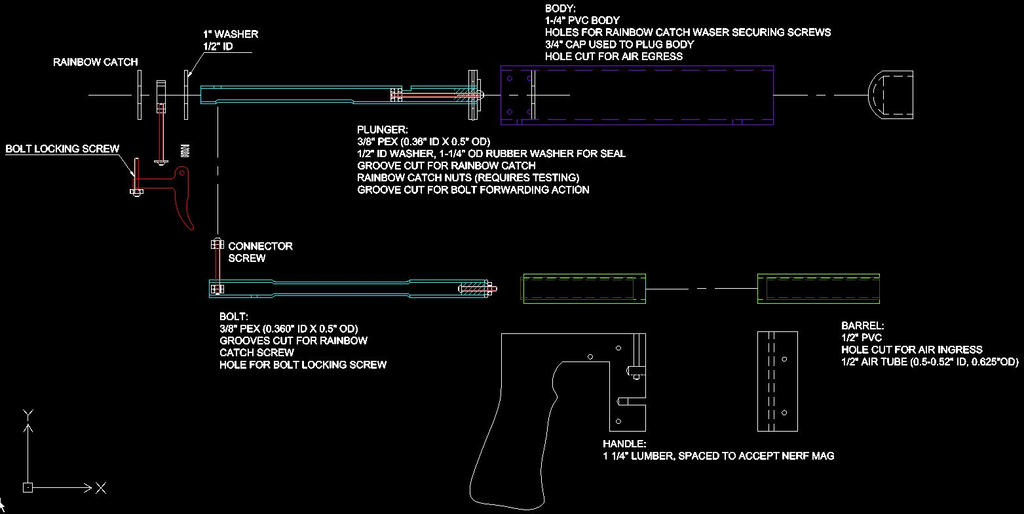

Stacy R3

In this iteration, I've removed the single action nature of the bolt/plunger, instead opting to have the bolt pushed forward by the wielder in order to seat the round. The plunger rod and bolt are both made from 3/8" PEX, the body is a more traditional 1-1/4" pvc, and the barrel/breach is made from 1/2" pvc with a 1/2" pneumatic tube liner. The pneumatic tube should give me the tighter barrel diameter that I need to fire these darts more efficiently, and it can pretty easily be opened up by a millimeter or two if need be. The connector screw is used as a cocking handle, pulling back the plunger and bolt simultaneously, the groove in the bolt allows it to move without interfering with the rainbow catch screw, and the groove in the plunger allows the connector screw to move forward freely to allow the bolt to seat the dart. The bolt head has an O-ring on it to seal in with the pneumatic tube in the barrel, and a screw/nut to push the dart forward without crumpling the foam, and moves the back of the dart forward of the hole connecting the plunger body & barrel. The plunger head is a rubber washer squeezed between two flat washers, and I have a long screw going down the length of the plunger for added support, I'm hoping that the rainbow catch will work on the nuts on this screw instead of putting all of the spring force on the plastic PEX.

The only thing I'm not feeling 100% about on this design in the 3/8" PEX being used as the plunger rod, because it is relatively soft and I feel like it will get torn apart by repeat use, particularly at the connector screw and the rainbow catch areas. The addition of the nuts on the plunger to catch on the rainbow catch are my attempt to help mitigate wear at that point, but I honestly don't know if it's worth the effort. Has anybody else tried something similar? What was the life-span of your part?

Thank you for your time and considerations