If I understand your R2 design correctly you are using a spring to compress air via a piston/plunger, and then release it all at once the bolt has closed the breech? That's really cool, interesting, and some food for thought.

But I don't think you actually need to do something so precise as all that. You could instead have the bolt slide forward immediately after priming. One way to do this would be to cut a slot in the plunger rod like in the Tornadobow. So you would pull back both the bolt and the plunger, then when you let go the bolt is slid forward by a light return spring.

Also if you are worried about the bolt being pushed back by air pressure during firing (like in Boltsniper's FAR) you could have the trigger interface with it just before it releases the catch. When you release the trigger, the bolt will be free to be pulled backwards along with the plunger.

Oh, and since the dart isn't going into the bolt you shouldn't need the "half pipe" section of the bolt. You'd be better off with a cylinder or a cone at the front to simply push the dart forward into the barrel. You'll need to use a tighter barrel than 1/2" PVC by the way (you are using micro darts/elites right?)

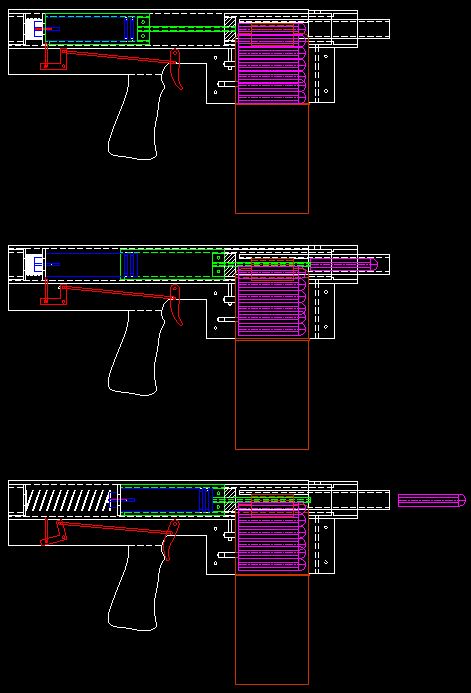

I had thought of doing exactly that, putting a spring just forward of the trigger inside the bolt and securing it with a screw so that when released, the bolt would slide forward and seat the dart while the plunger arm remained secure until firing. The reason I didn't pursue it was because I didn't trust a weaker spring to be able to force its' way through the mag, overcome all that friction and pick up a dart. I have a Retaliator and I have to apply considerable force to push the action forward, I don't feel like a weaker spring would be able to overcome that force reliably. Not to mention the added cost of the spring, which is already the most expensive part of this build. I may put a slot in the plunger arm and manually push the bolt closed, which should actually improve the spring efficiency for firing as it doesn't have to overcome all that friction from seating the dart, but I'll leave that as something to test after trying this single action plunger/bolt hybrid. I can always cut the slot afterward, but I am VERY curious to see if this works at all.

Just a quick question on the spring by the way. In this model I'm using a [k26] spring from Mcmaster cut to 4.75" (I realize I could get away with 5.5", but I'm being conservative), which in and of itself is fairly cheap (a pkg of 5, 11" springs for $12-ish) but the shipping is literally more expensive than the actual spring. Is that just the unfortunate truth of getting this spring, or is there a more cost effective means of getting one? Is there an analogous spring that's less expensive to acquire?

Anyway, back to Mr. Jwasko's points, as for the bolt being pushed back, I actually hadn't even considered that a possibility. With the current design, I doubt the air released would be able to push the bolt back just based on the spring keeping it forward, but if I were to manually push the bolt forward, I would have to do something. A secondary catch that engages when the trigger is pulled if a fantastic idea, and I'll definitely keep it in mind should I go that route.

The 'half pipe' of the bolt is actually serving several functions in this design, and while I would love to be rid of the damnable thing (not looking forward to cutting that) its utility outweighs its annoyances. As it stands, it acts as a 'guide' between the two sections of 1/2" pipe that make up the barrel and breach, cutting a 1/2" pipe that would accommodate the mag would be even more annoying and basically have a 1/4" 'sliver' running between the two pieces. Secondly, it's a sort of secondary securing system for the mag since a 5/8" OD fits very snuggly inside that dart retainer at the top, and the mag will 'snap' over the edges of a 5/8" dowel without issue. It makes the mag harder to remove for reloading, but not too hard in my opinion. Lastly, it makes the 1/2" barrel a little 'tighter' since, as you say, a 1/2" pvc pipe is too loose to house an elite dart.

I don't have any better options for a barrel though since the dart is just a little over 1/2" and there is no PEX, CPVC or PVC pipes, or fittings that would have a tighter ID. Right now I'm sort of stuck on that. If I could make my own darts, I'd just use the PEX bolt and scoop them right into a matching barrel. The closest thing I can think to do is take the other half of the 'half pipe' part of my bolt and try to sand down the ID so that I can place it in the barrel to shore up the ID difference. Any other options for a barrel with an ID just over 1/2"?

EDIT:

I completely forgot about 5/8" PEX, which has a 0.584" ID, where the Elite dart has a 0.511" OD, so they are much closer. There's still roughly 2mm clearance, which is quite a bit, but I might be able to make that up with a duct tape liner?

Edited by TulipMama, 26 October 2016 - 11:09 AM.