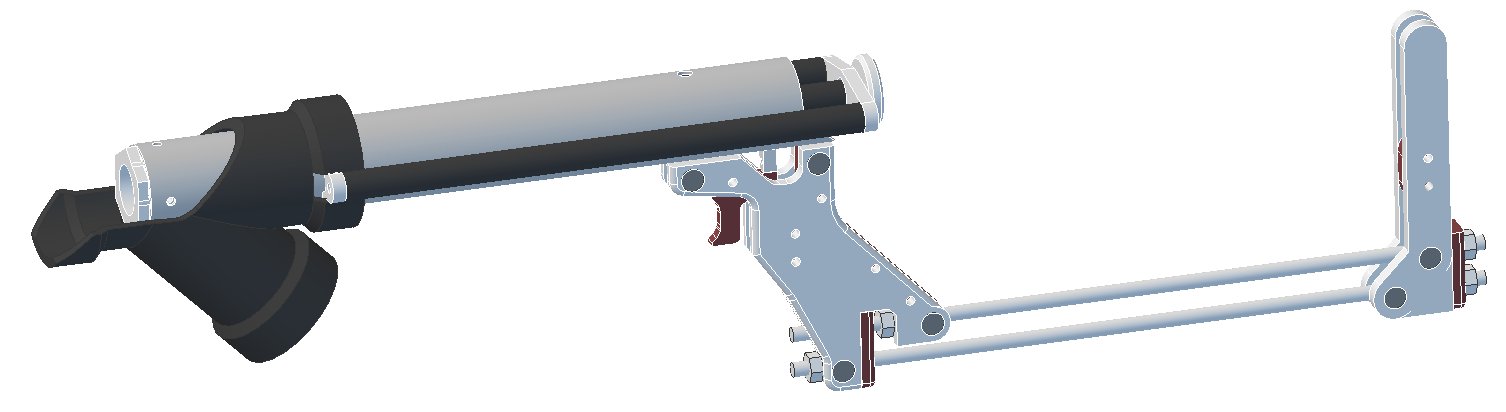

While I would agree that the tooling required to build one of these is fairly minimal, I disagree that the blaster could be designated as a beginner's blaster. I'm not harping on the design, it's simple and beautiful, but it requires too much material from McMaster or online sources, while SNAPs and the Mark 8 can basically be built after a Lowes trip.

The only hurdle there is having a payment source that McMaster accepts. If you don't have a credit card (due to being too young or other) it's pretty easy to just go to any retail store and use cash to buy a VISA\AMEX\MC gift card. You can then use that to place your order online.

I've explored trying to come up with a hardware store only blaster a few times and haven't come up with anything really worthwhile. My particular location has become even less receptive to it being an option.

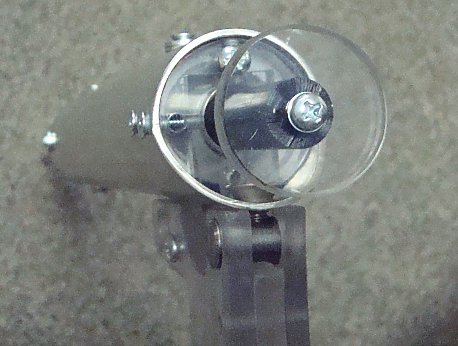

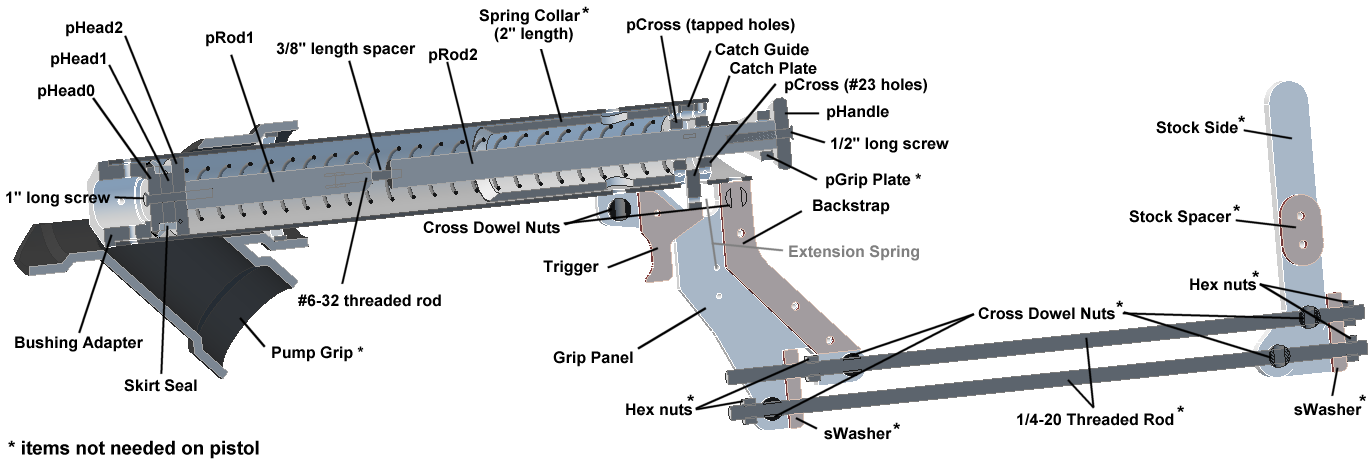

The only plunger head you can make from either Lowe's or Home Depot is a superlative one.

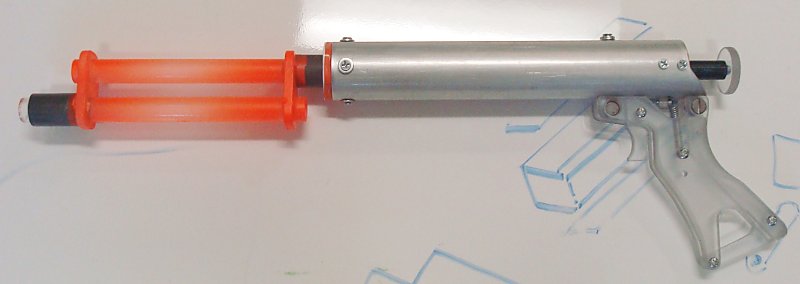

And the options available for springs is very very limited. The only springs I've found that's worthy of using for a full-power homemade are the ones you can extract from the inside of door closers. They're 19-inches long and have a wire diameter of .080". The OD of them depends on which diameter of door closer your buy. These come with an o-ring plunger head, but the plastic it's made out of is not going to survive the abuse of being slammed into the end of a plunger tube.

The last remaining hurdle is being able to source polycarbonate. I used to have a local source, but they closed that part of their business. And none of the hardware stores near me carry any that's thicker than .093". And to make things even less desirable most of the plastic pipe that my local locations stock has a terrible interior surface finished that's full of pits.

All of these issues combined are making it very unlikely that I'm ever going to develop a blaster that you can make from any hardware store location as a primary source of materials.

The little critters of nature, they don't know that they're ugly. That's very funny, a fly marrying a bumble bee. I told you I'd shoot, but you didn't believe me. Why didn't you believe me?