I had planned to do a full writeup with step-by-step instructions and pictures and all that, but as months of non-work turned to years of non-work, I decided I should get this out to the community in whatever form it took. By now nothing in this blaster is in any way new or revolutionary, (with the possible exception of the Dura brand PVC bushing trick) but I want to have this information out there.

I’d like to give credit to the rainbow clan for the rainbow catch, Ryan and Kane for the BullPAC and the original Rainbowpup, Carbon for the Snap/Revolution, Ryan for the original catch and handle templates, and Diamondback for the slightly modified ones.

In lieu of an actual writeup, I’m uploading the .dwg and template file that I have now. They are included as attachments at the bottom of this post. If you don’t have autocad, you can download draftsight for free at http://www.3ds.com/p.../free-download/ and it’ll do all of the same things. Alternatively you can find various free viewers (not editors) at http://www.autodesk....cts/dwg/viewers. I’m also including various pictures of the only one of these I still have, so you can get an idea of what the actual parts look like, especially where I wasn’t super detailed in my .dwg. The pictures I include are of a somewhat earlier revisions than what the .dwg shows, so be aware of that.

Parts needed.

Here’s the part I think is least clear in the .dwg: what I call the seal block. This is what seals the plunger rod. It’s made from a 3/4" to 1/2” PVC bushing nested inside a 1” to 3/4” bushing with a 9691K53 U-cup seal sandwiched in the middle. I cut down the outer lip of the U-cup to about half height. The PVC here stops the plunger when it hits home. I use SCH80 PVC since the thicker walls provide a little more surface area for the plunger head, but I don’t think it’s that important.

The rainbow catch is directly in front of the seal block.

Here’s my plunger head. It’s a little longer than the one in the .dwg, but concept is similar enough. You can use whatever you like here to interface from the nylon plunger rod to the skirt. The .dwg and parts list use a U-cup since it’s cheaper, but I used a skirt for this one because this was the first one of these I made. Use whatever you like, but keep in mind the skirt is 1/8” taller. Those grommets there provide a little cushion when the plunger head hits home.

This is the front of the plunger rod. I use a really long eye bolt to mount both the spring and priming disk to, as well as providing room for the catch, which works against the front surface of the nylon rod.

You can use a long set screw or cut the head off a regular screw to support the spring at the front. I use these things called weld nuts to hold the spring centered on the screw.

The priming grip is simple enough, but I want to point out the screws that poke in through the slots and push on the priming disk. That is how this blaster is primed. Also, the slots on the top and bottom need to be the right size to be out of the way. The .dwg shows the priming slide being stopped when the bottom slot hits the front of the handle/trigger block, but this one here stops when the plunger bottoms out against the catch. An important thing here is that you can’t really use thinwall 1-1/2” PVC for the pump grip. The walls are too thin and flex inward with those slots cut.

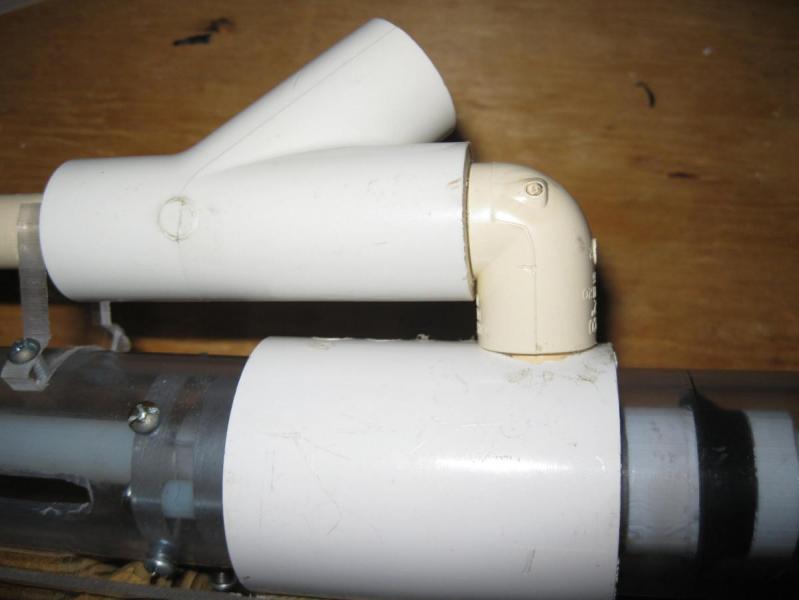

Finally, the redirect. For the actual elbow part I use a 1/2” CPVC street elbow, with the spigot end hammered into a short piece of 1/2" PVC to interface with the wye. The socket end has a short piece of CPVC in it. I just drill a hole in the coupler and plunger tube and insert the CPVC into that, but you can do various things here. I use a 5/8” forstner bit and my drillpress to make this hole, and it seals perfectly without glue, but you may or may not be able to do this, depending on your tools.

The template file is attached to this post. I can't attach .dwg files so I put it on google drive: https://drive.google...Ym9VaGtfSkZSLW8