Alright, I've got some new pictures and some new info.

First and foremost, here's one of my later attempts. It's much less wrinkled than the original. It's still a bit warped in places; this would be easier if I had both hands to manipulate the PETG, but I can't find my Zippo.

On a related note, I realized that this method has a much different fit and use than the spring method. I didn't remember at first, but I made another ringed barrel for comparison's sake and realized that it's much looser than the stretched PETG.

As you can see, the stretched tubing has a springer fit:

and the ringed tubing has a loose push fit, somewhere between airgun and springer:

I believe MIG was trying to create something to replace the brass stubs in turreted airguns, and for that purpose, his method works perfectly. However, I was trying to create something that would allow me to use airgun PETG, which is thin and cheap, as a springer material to replace the barrels in blasters like the maverick and to replace seated brass in stock barrels. I feel that the stretch method accomplishes this better.

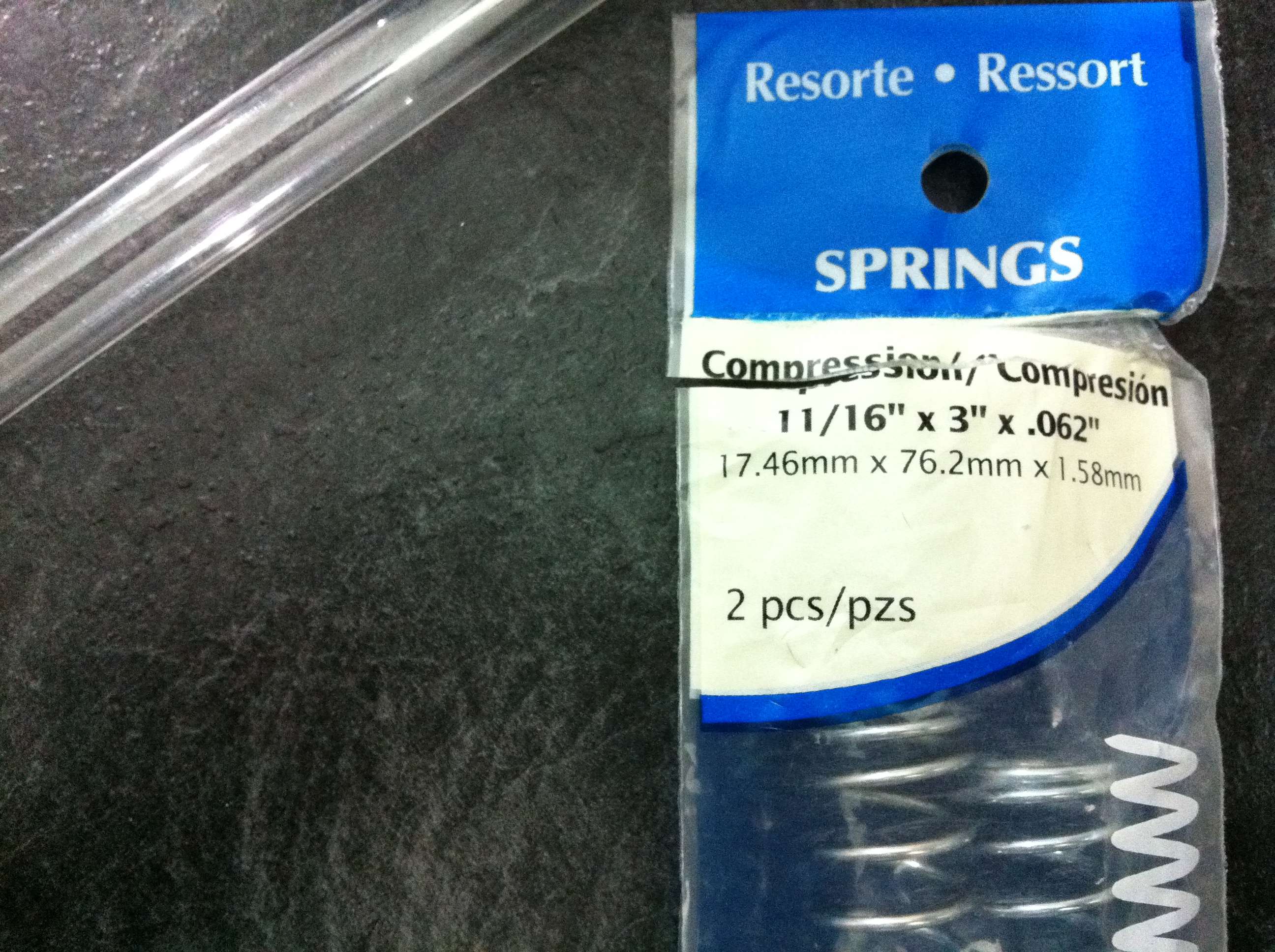

It is very possible, however, that I messed up MIG's spring method and used the wrong sized spring or something, and that is what's affecting the dart fit. I couldn't really imagine trying to fit a tighter spring on, though.

With the effort it takes to do this, I would say just buy the 17/32 brass and slip it in the PETG. Assuming you place a mcmaster order to get your PETG, adding 3 lengths of brass is only 10 bucks more. Small price to pay to save you the effort of dealing with fire and iffy methods. Not only that but stretching it also weakens the PETG. Using this in a high powered springer would most likely cause it to shatter.

10 bucks is a lot to me. Gotta eat.

Is there really that much energy transferred into the barrel? I guess I'll have to test it out.

*edit

I nested a piece in PVC and then took several shots out of my snapbow. I don't think it's going to break any time soon; how many shots would you expect before it cracks/shatters?

ANY wrinkles would cause a sealing problem, as they run the length of the barrel. Tightening rings run perpendicularly and would not have the same issue.

Not at all. I'm saying that it is unlikely to be able to be shrunk consistently using even heating sources, and using flame is just retarded.

The wrinkles are small enough that any war-legal darts have enough foam to seal both sides before escaping air would be an issue. Here's what I mean:

Compared to the spring method:

The wrinkles can also be avoided, or at least minimized, like in the newer barrel. The spiral rings created by the spring method allow a small channel for air to pass through and get ahead of the dart. The leak is still probably negligible, but from blow-testing (yeah, I know, I'm gay) some air escapes around the dart in my ringed PETG and no air escapes in the stretched PETG. This may be a result of the looser dart fit/me messing up,though.

It's consistent enough. I don't own a heatgun, and the hairdryer was too loud to use (During weekdays I mod ~midnight-2 AM). I'll give it a go with the hairdryer this weekend and see if I can improve results. Using fire isn't

retarded, but I do agree that a heatgun would be a better path. So far I haven't burned myself, and I think it would take an awful lot of incompetence for someone to do so. You're really more likely to hurt yourself making glue domes.

Twisting the PETG whilst pulling it apart could possibly result in better air seal and a "rifled" barrel!

The spirals would actually provide channels through which the air could escape.

Rifled barrels do absolutely nothing to improve range or accuracy of nerf darts. The trajectories are too different.

Is there any noticeable difference like range, and/or accuracy?

If you're still wondering, yes. It depends on your darts, but if they have a "springer" fit (tight push fit) in 17/32" brass then they will have a very similar fit in this.

Upon review, yes they would. On another hand, use a candle for the flame as it requires no hands to operate past the lighting.

I thought about using a candle, but all of mine are sunken too much. Maybe if I can find one without big wax walls.

Edited by Samurai_kidd, 21 February 2013 - 08:34 AM.