Still too bulky for my tastes.Its got less barrels .Or is it still too heavy

I will e keeping them as separate files.You said you will be editing the construction write-up; will you still have a link to the original? I am curious because

Posted 07 September 2008 - 12:47 PM

Still too bulky for my tastes.Its got less barrels .Or is it still too heavy

I will e keeping them as separate files.You said you will be editing the construction write-up; will you still have a link to the original? I am curious because

Posted 07 September 2008 - 06:22 PM

By changes to the part list will this make the list cheaper, or just allow for you to modify the grip, trigger, plunger handles, and rear frame piece. Just curious because I am getting a scroll saw soon and once I get a feel for it I will begin construction on this. Also, whatever happened to the wob+ and Arr. I'm assuming you don't have enough free time but are you planning on finishing these eventually.+Bow Rev.2 is forthcoming.

I've made a great deal of minor changes to the original design that will require me to edit half of the steps in the construction write-up. The update includes changes to the grip, trigger, plunger handles, rear frame piece, and part list.

Edited by Foam_Shooter, 07 September 2008 - 06:24 PM.

Posted 07 September 2008 - 07:15 PM

1. It will make the part cost slightly cheaper ($75 not including label paper cost). The changes substantially increase the comfort level of the blaster.1. By changes to the part list will this make the list cheaper, or just allow for you to modify the grip, trigger, plunger handles, and rear frame piece.

2. Also, whatever happened to the wob+ and Arr. I'm assuming you don't have enough free time but are you planning on finishing these eventually.

Edited by CaptainSlug, 07 September 2008 - 07:17 PM.

Posted 08 September 2008 - 07:12 PM

Edited by Blasphemy, 08 September 2008 - 07:19 PM.

Posted 08 September 2008 - 07:16 PM

'tis trueAnyways, to save dollars for those who want to, I want you to know you all to know you can squeeze all of your 1/8" components onto a sheet of 12" by 8" if you can find one.

Posted 08 September 2008 - 09:26 PM

'tis trueAnyways, to save dollars for those who want to, I want you to know you all to know you can squeeze all of your 1/8" components onto a sheet of 12" by 8" if you can find one.

Rev.2 partlist includes this update.

Posted 08 September 2008 - 09:47 PM

Posted 09 September 2008 - 04:49 PM

Edited by Blasphemy, 09 September 2008 - 05:02 PM.

Posted 19 September 2008 - 12:59 AM

Edited by CaptainSlug, 19 September 2008 - 01:47 AM.

Posted 19 September 2008 - 10:14 AM

Edited by Langley, 19 September 2008 - 10:17 AM.

You can poop in my toilet anytime champ.

2016 Nerf War Schedule

Bless you, my son. Now recite 3 New Members Guides and 5 Code of Conducts for your sins.

Posted 19 September 2008 - 12:57 PM

Posted 19 September 2008 - 05:57 PM

Excluding the plunger and catch plate:What parts are under stress from the spring aside from the catch and plunger?

Edited by CaptainSlug, 20 September 2008 - 09:07 PM.

Posted 19 September 2008 - 07:01 PM

Excluding the plunger and catch plate:What parts are under stress from the spring aside from the catch and plunger?

Secondary load bearing parts are the grip and plunger priming handles since those are used to provide leverage for priming the plunger.

Posted 19 September 2008 - 09:53 PM

Posted 20 September 2008 - 12:21 AM

Edited by CaptainSlug, 20 September 2008 - 08:45 AM.

Posted 20 September 2008 - 04:49 PM

Posted 20 September 2008 - 06:02 PM

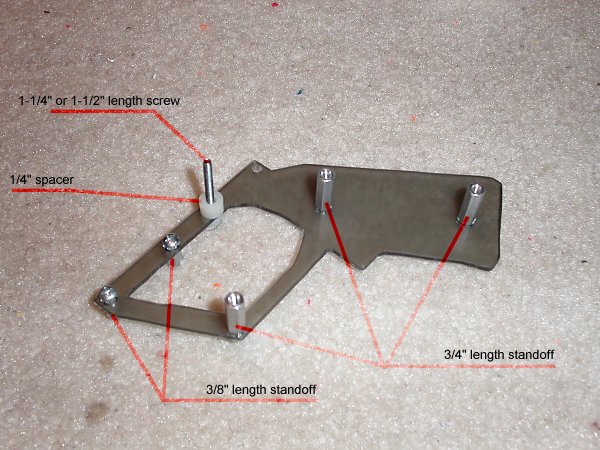

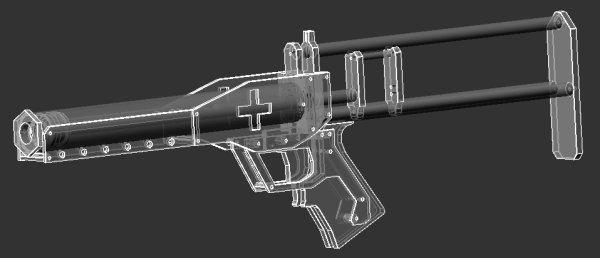

Another teaser.

*above picture*

trans as shit because fuck you

Posted 20 September 2008 - 08:43 PM

The new grip design requires that its edges be sanded or beveled by other means (like using a hobby knife). But the new design accomplishes the following.Another teaser.

*above picture*

From the looks of it, that handle has no foam. Did you make a molded handle, or is it just not finished?

I'm guessing the answers will come soon. Also, the frosty plastic looks nice.

Edited by CaptainSlug, 20 September 2008 - 08:59 PM.

Posted 20 September 2008 - 10:05 PM

Edited by rork, 20 September 2008 - 10:10 PM.

Posted 21 September 2008 - 01:07 AM

Edited by CaptainSlug, 21 September 2008 - 02:12 AM.

Posted 21 September 2008 - 01:29 AM

Posted 21 September 2008 - 01:32 AM

Yeah, you should be able to manage fine with some of the smaller jigsaw blades used for cutting plywood veneer. Those or metal smooth-cut blades.That's fantastic to know. A $20 jig saw is a lot easier to swing than a $100 scroll saw, and I already have access to a band saw. I'm really looking forward to seeing the rest of the rev. 2 design. On another note: McMaster's clear polycarbonate seems to be cheaper than the tinted stuff now. Is the frosted stuff on yours a special type, or is it a coating? Thanks a lot for the continuing tech support. ~Rork

PS: Are you talking about a 9/16" spade-type bit?

Edited by CaptainSlug, 21 September 2008 - 01:38 AM.

Posted 21 September 2008 - 01:40 PM

Edited by .Z4., 21 September 2008 - 01:42 PM.

Posted 21 September 2008 - 03:59 PM

You'll have to print out the new templates and use the scrollsaw to widen the shape of the existing hole to accommodate the the round plunger rod if you want to change over to it.I started cutting out the main 1/4" frame pieces for my second +bow yesterday, and already cut the centers out for the 1/4" plunger rod. Will it be possible for me to drill the pieces out for the Rev. 2 rod or do I need to recut them entirely?

Edited by CaptainSlug, 21 September 2008 - 03:59 PM.

Posted 22 September 2008 - 04:07 PM

All right, glad to hear it. Thanks a lot.You'll have to print out the new templates and use the scrollsaw to widen the shape of the existing hole to accommodate the the round plunger rod if you want to change over to it.

Stole the words right out of my mouth...And now I'm very very happy with it.

Edited by .Z4., 22 September 2008 - 04:42 PM.

0 members, 1 guests, 0 anonymous users