Thanks SHA. Yeah, I took the pictures outside today on a white table. Down here in SD, it was

really bright so I had a hard time seeing the pictures I took when I was taking them. I'm surprised that not all of them turned out like that.

Part II

Here's how it works:

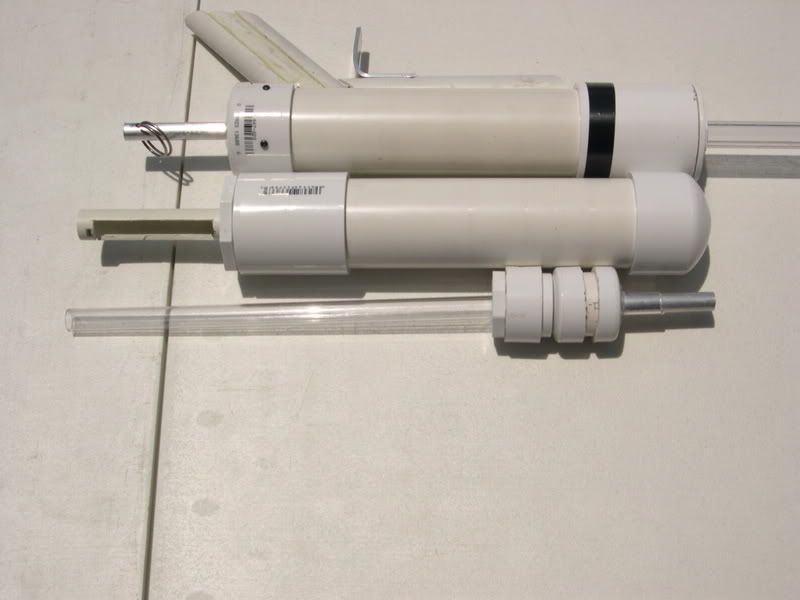

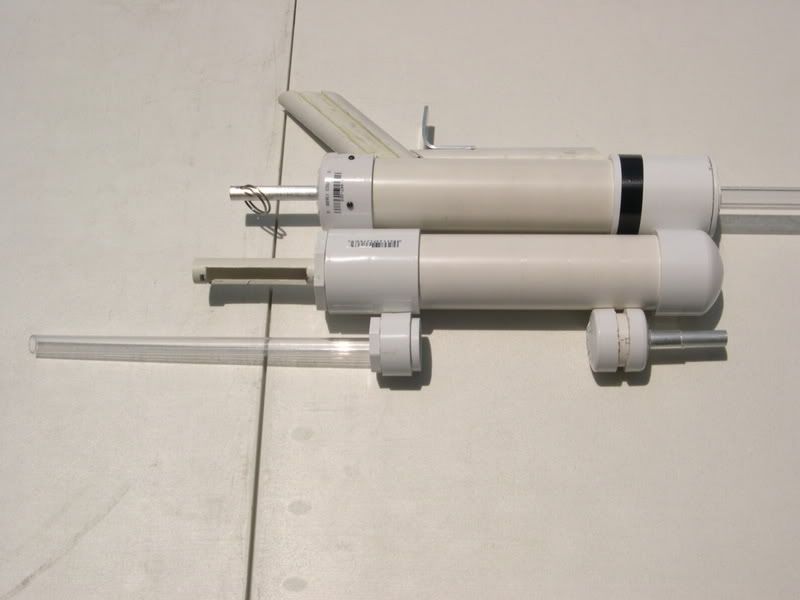

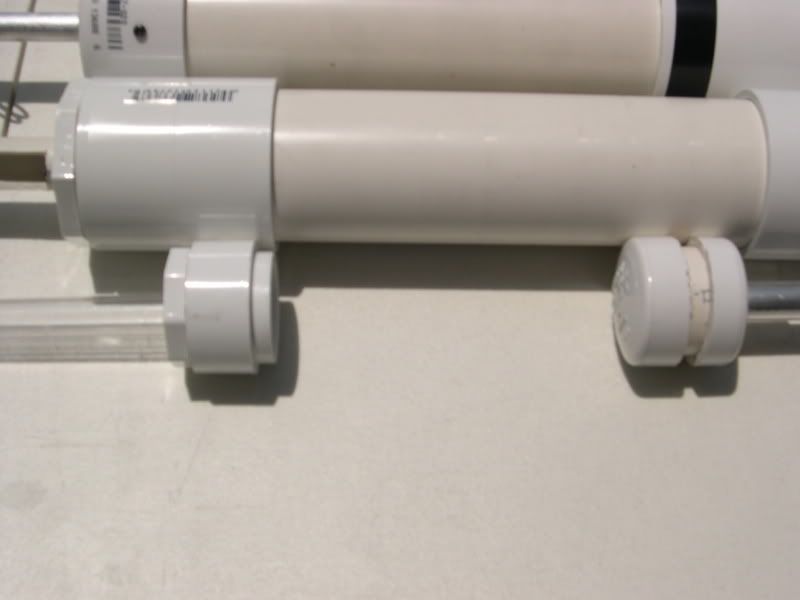

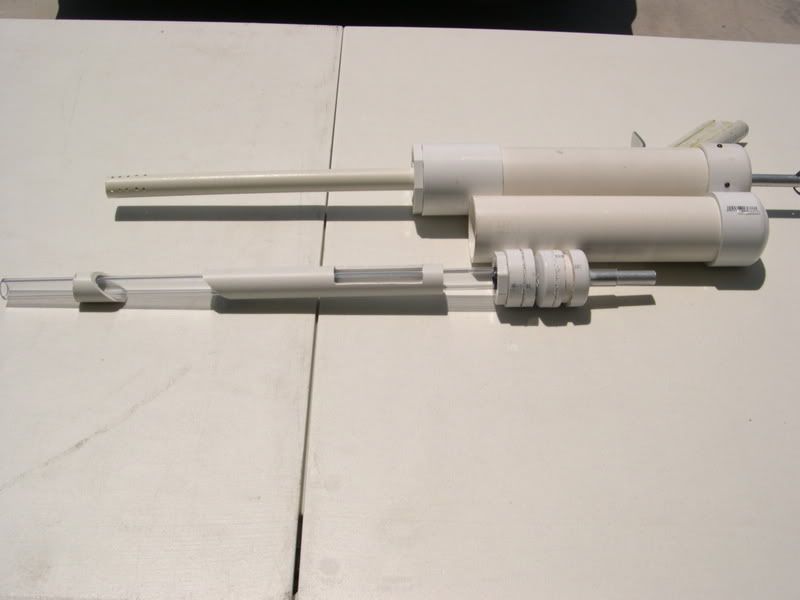

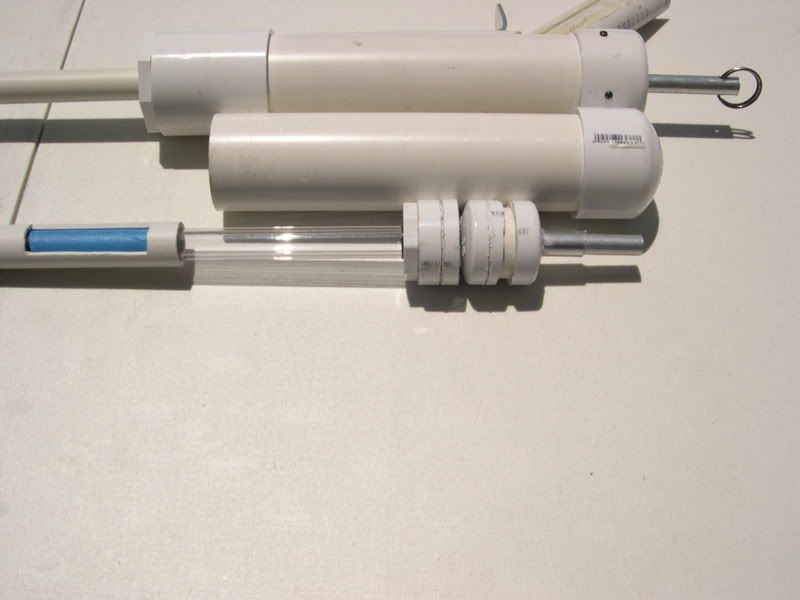

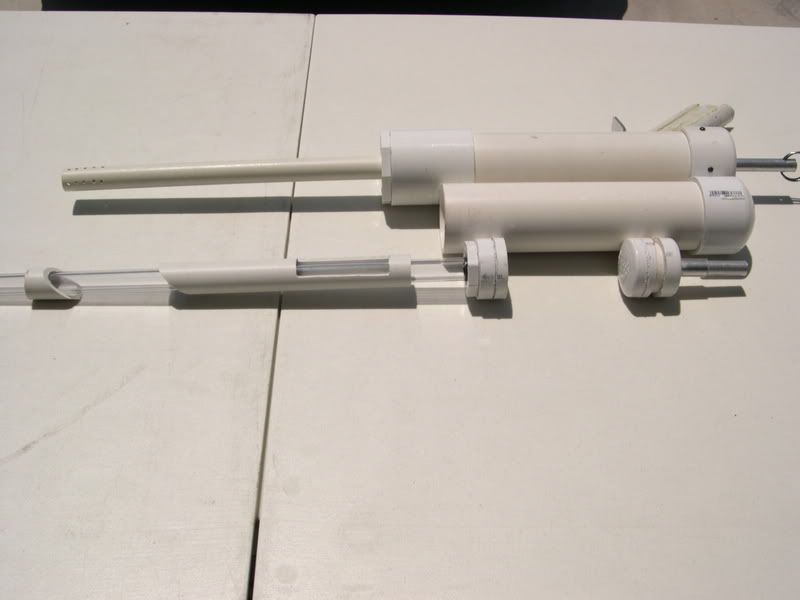

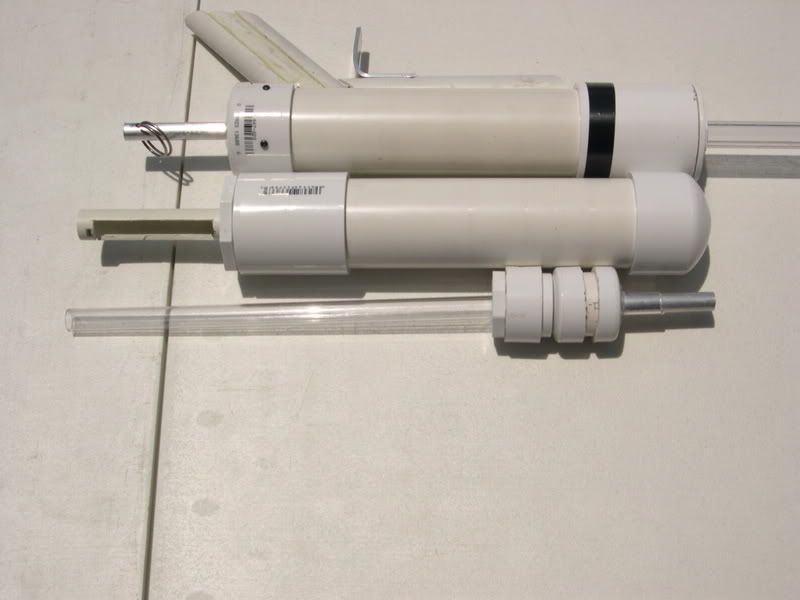

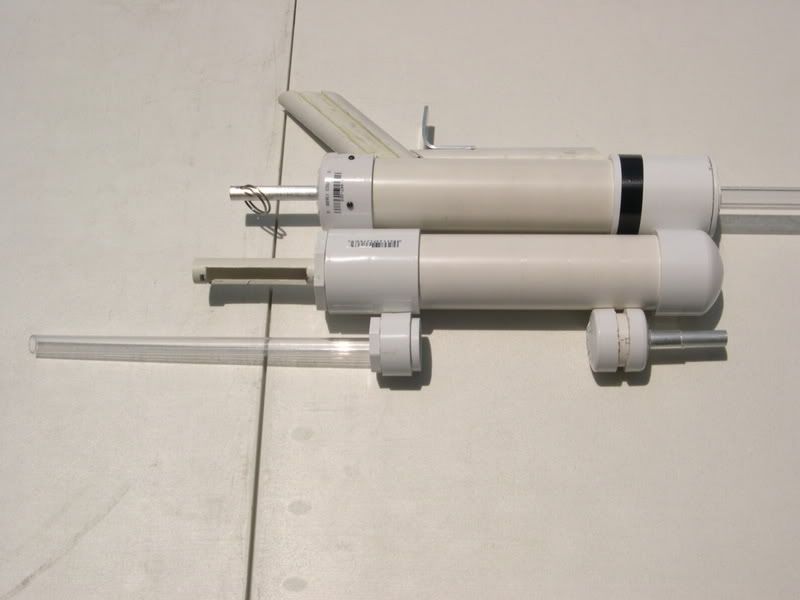

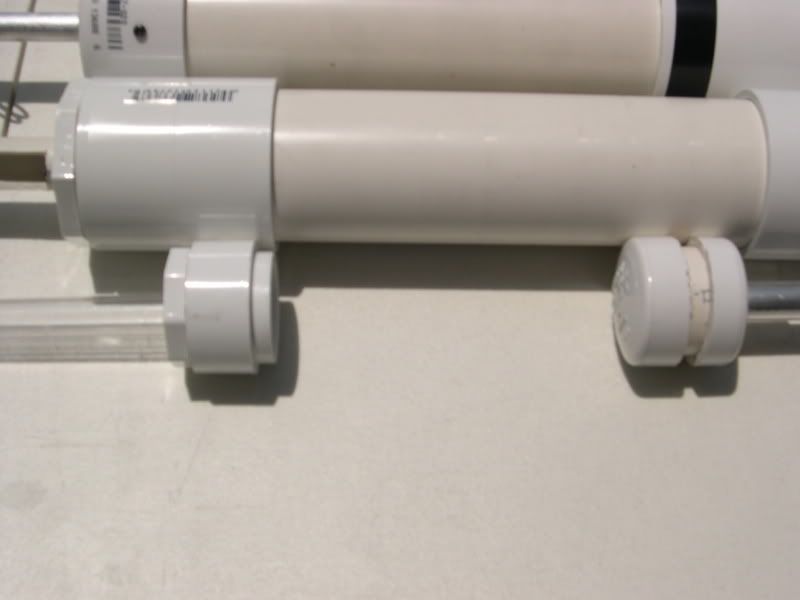

The PETG nested inside the 1/2" PVC will be able to slide freely back and forth inside the PVC, which will be secured to the gun by the 2"-1/2" reducing brushing. The PETG will act as the barrel. At the back of the barrel will be a 1 1/4"-1/2" reducing brushing with a small section of 1/2" PVC. I plan on gluing the PETG to the inside of the 1/2" PVC so the brushing is secured to the barrel. On the outside of the brushing is part of the 1 1/4" endcap I used for the plunger and an o-ring on top of that to seal the barrel and the pressure chamber. Right behind the barrel is the plunger made of 1 1/4" endcaps and tubbing. Instead of a gasket system I will be using o-rings to decrease weight. I also used a small section of 3/8 aluminum and glued that to the plunger.

When the barrel is pushed back, it pushed the plunger back with, similarly to the way ompa's SCAR works. It will be pushed all the way back until the plunger is locked into place by the clothespin trigger. And at sometime when the barrel is pushed back, the breach in the PETG will match the breach in the PVC opening a whole and allowing me to put a dart inside the barrel.

Once the plunger has caught onto the clothespin, I will move pull the barrel forward, closing the breach and

allowing the gun to be ready to fire.

Short term problems:

1. My barrel is too short (12") I will need at least a 16" barrel if I want to be able to attach a grip on the barrel to hold onto while pushing it back. I also think the air output is sufficient for a 16" barrel.

2. I don't have any o-rings on the plunger or on the barrel. This can be fixed, I just need to figure out what size o-ring to buy.

3. I don't have springs right now. I plan on using two, full length Handyman springs from Home Depot, just like in my Big SNAP.

4. I have yet to build a handle, trigger, or cover. I already have all of the materials it just takes some motivation.

Long term problems:

1. I'm not so sure on how to build the breach on the barrel. I don't know where I should put on the PETG and if it will be close enough to the back of the barrel.

2. I'm worried about the springs. Since I'm not using a full length of aluminum and I'm using two springs instead of one, I have no idea whether the springs will fold or come off the plunger.

That's about it. Questions, comments, and ideas would all be really helpful right now.