McMaster is very user friendly and it's easy to find things if you look.

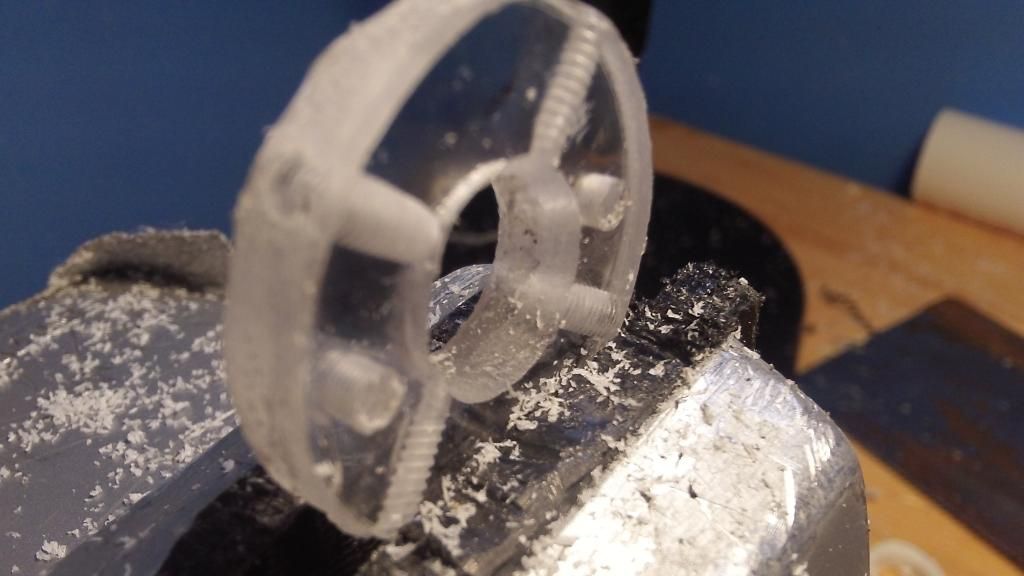

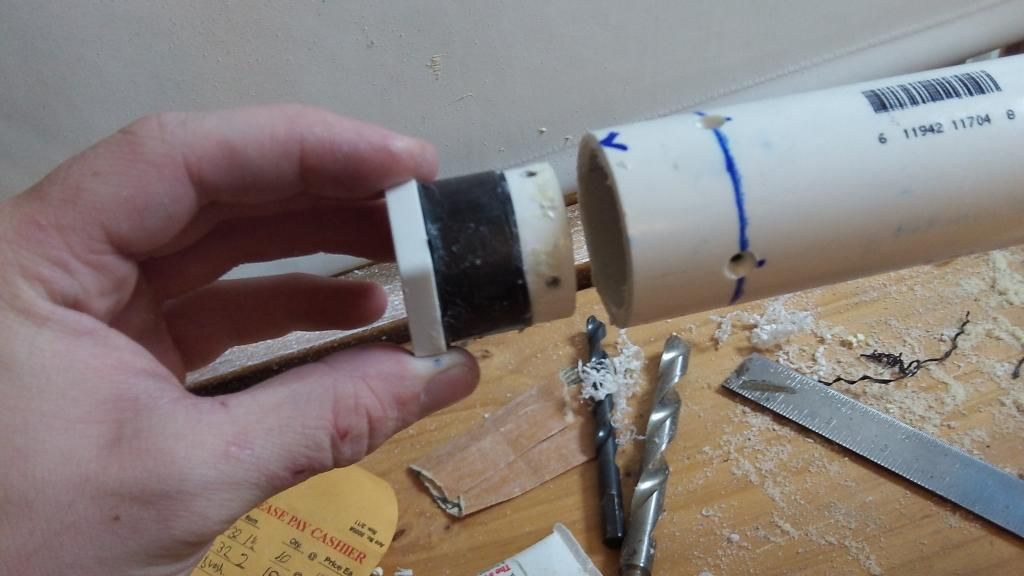

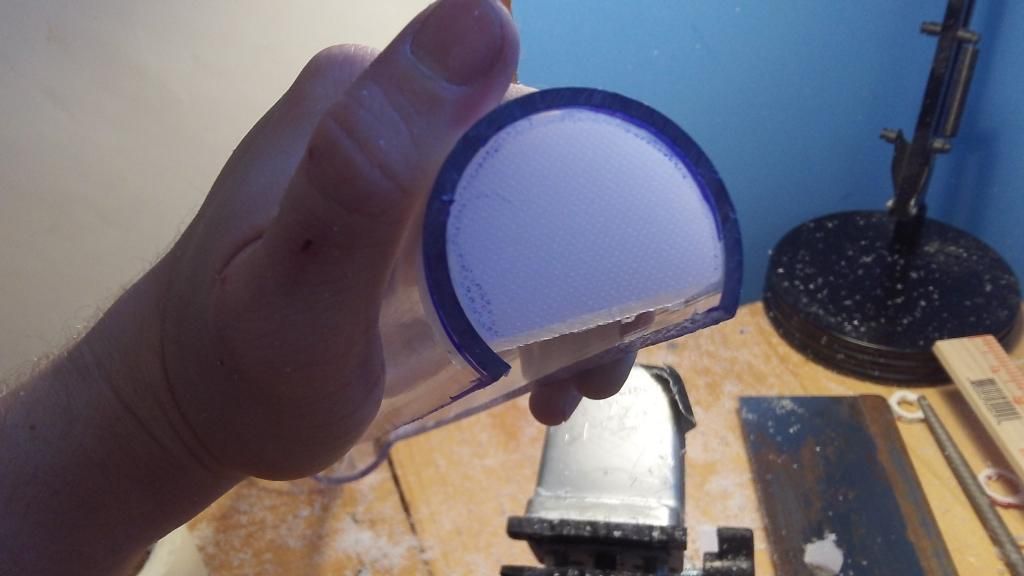

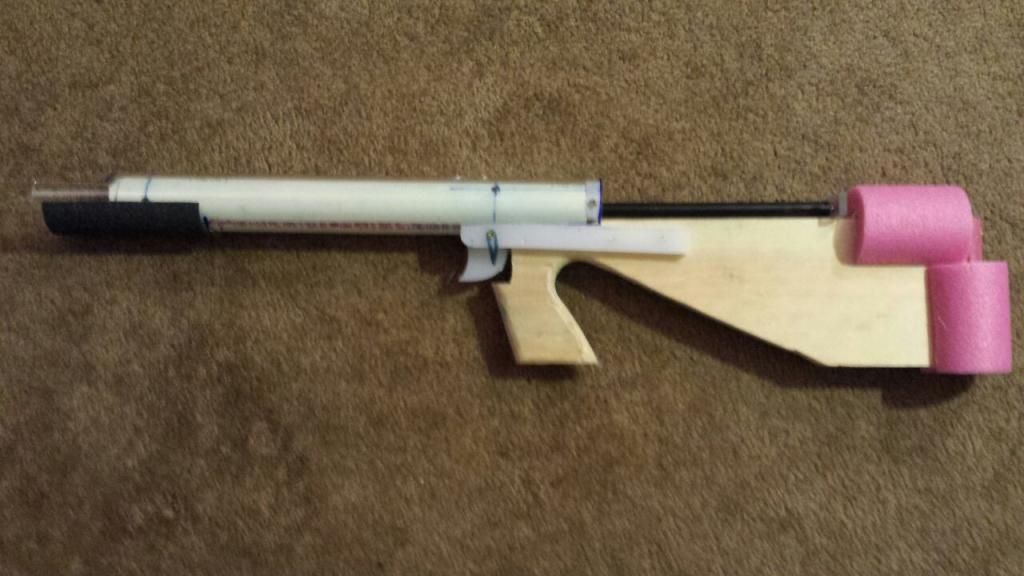

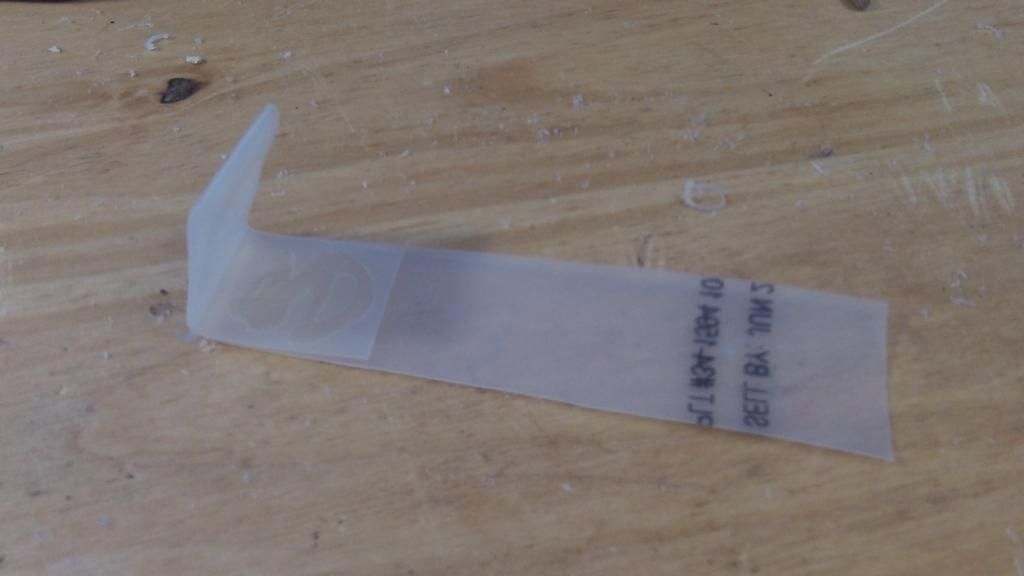

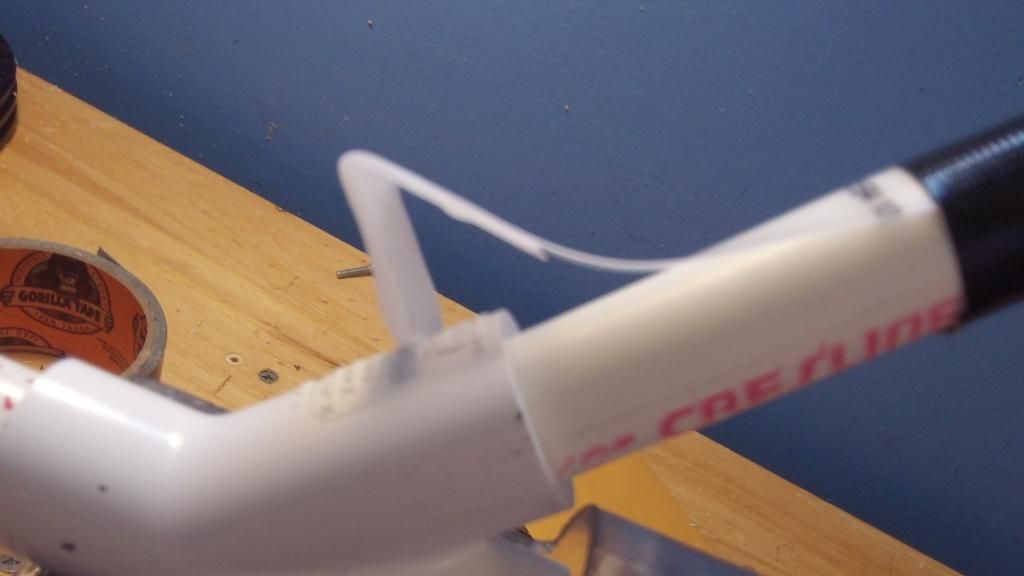

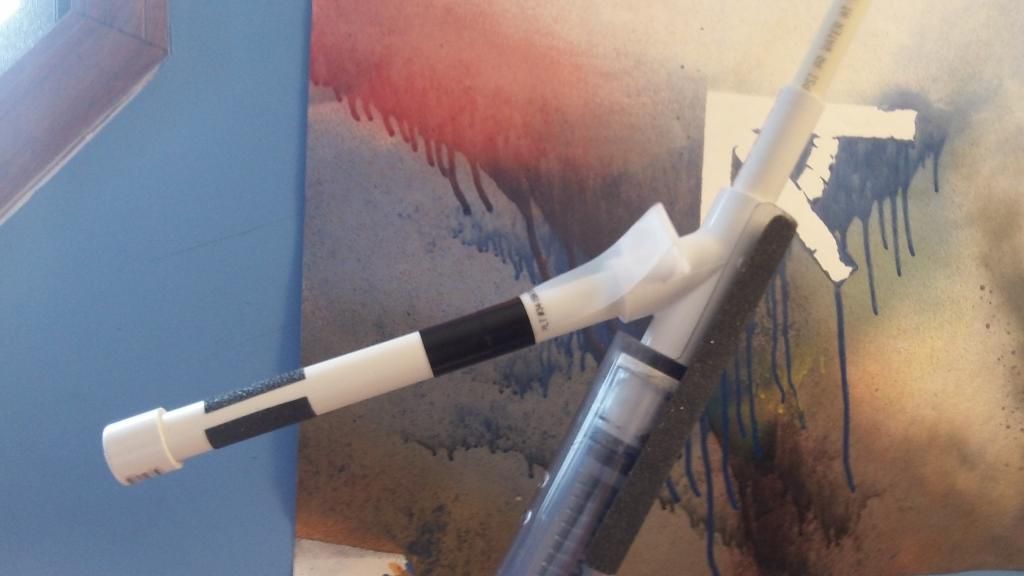

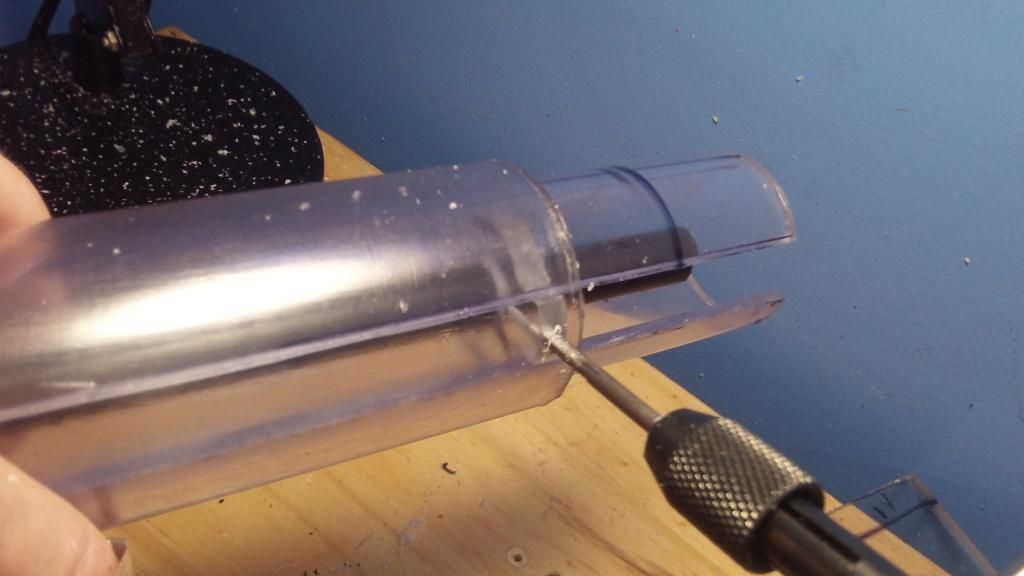

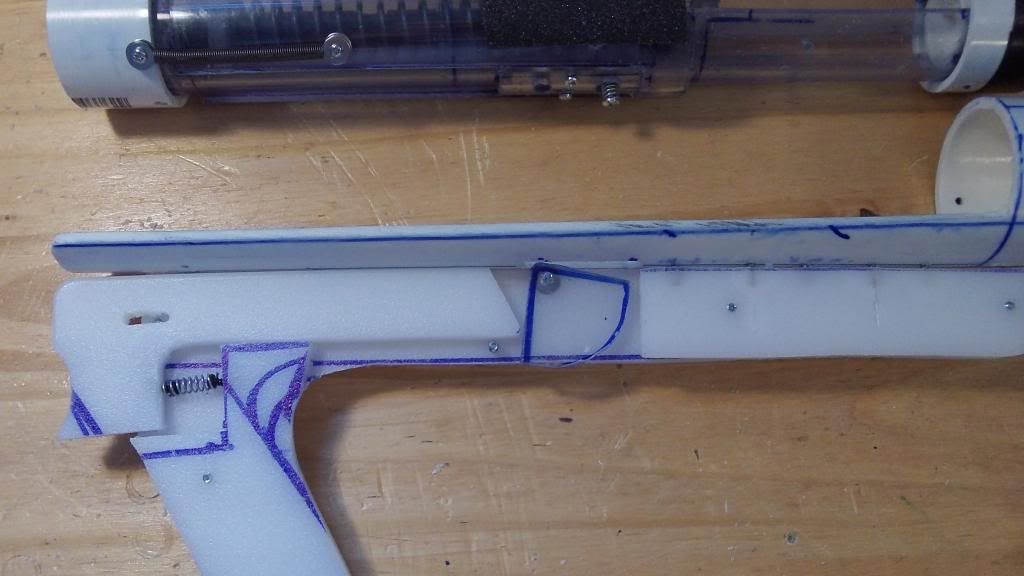

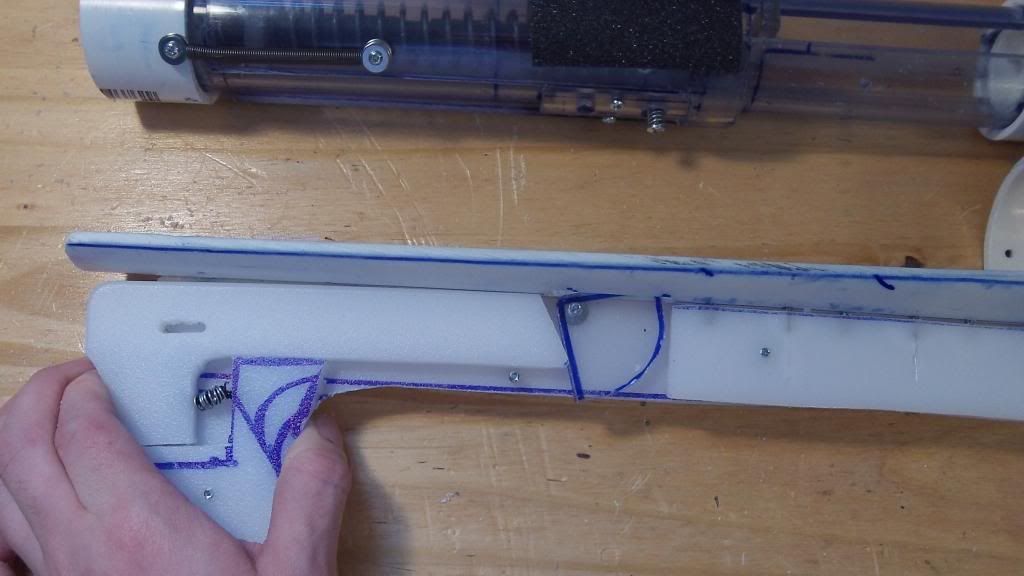

Thank you for answering that. The plunger head on this ended up breaking during APOC so I will definitely be revising this design.

Apologies to Aeromech for using his thread to promote my wares.

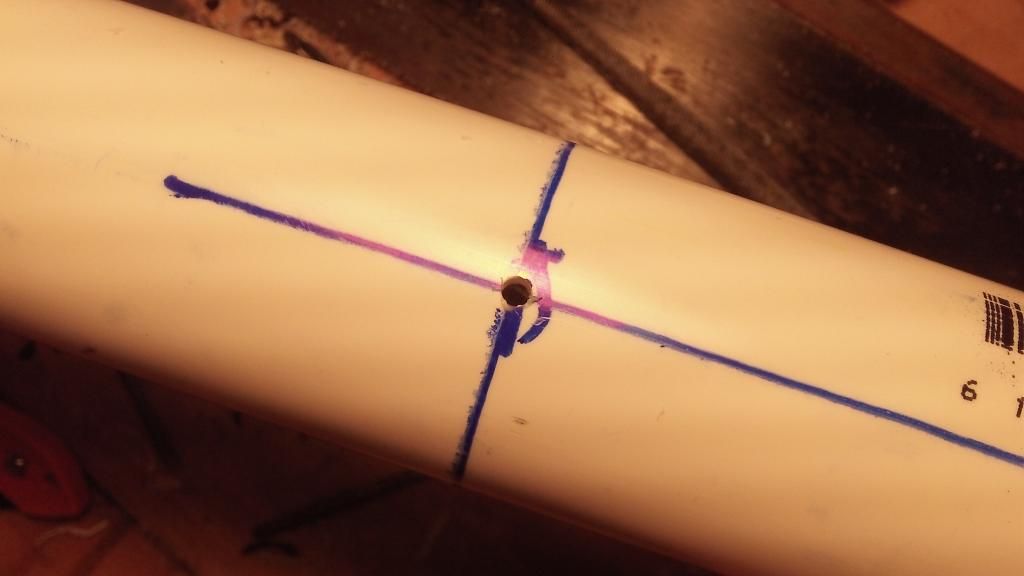

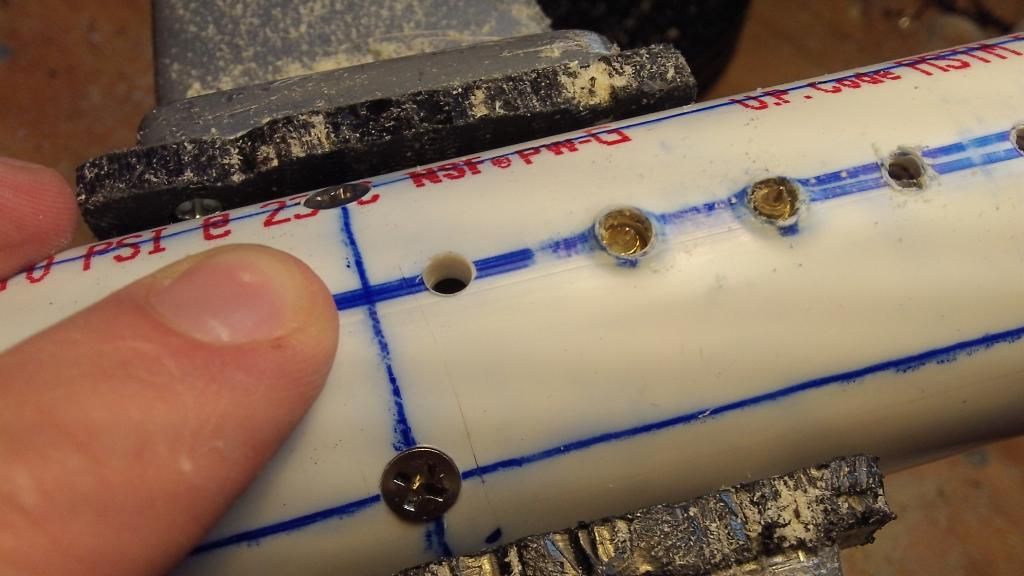

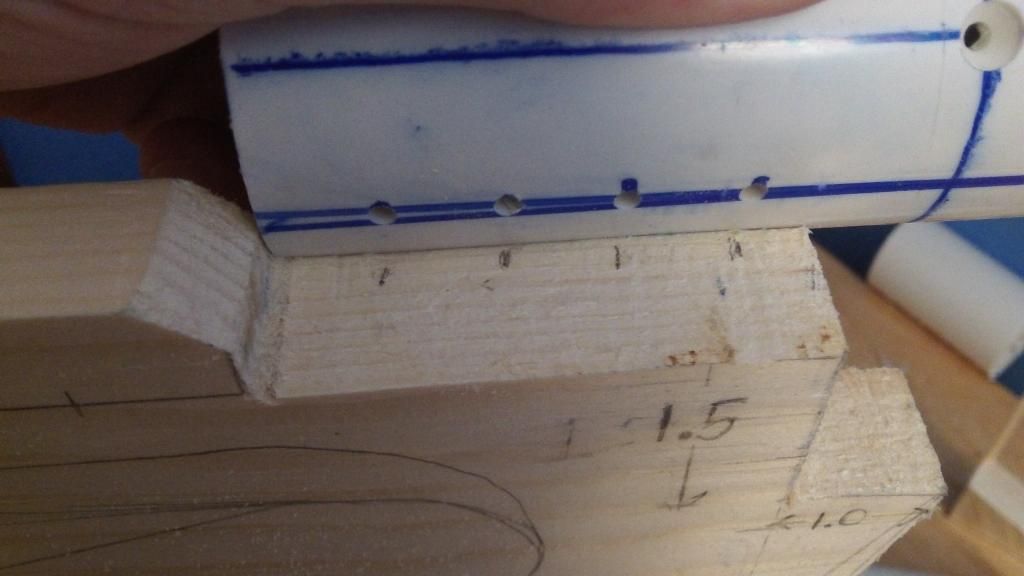

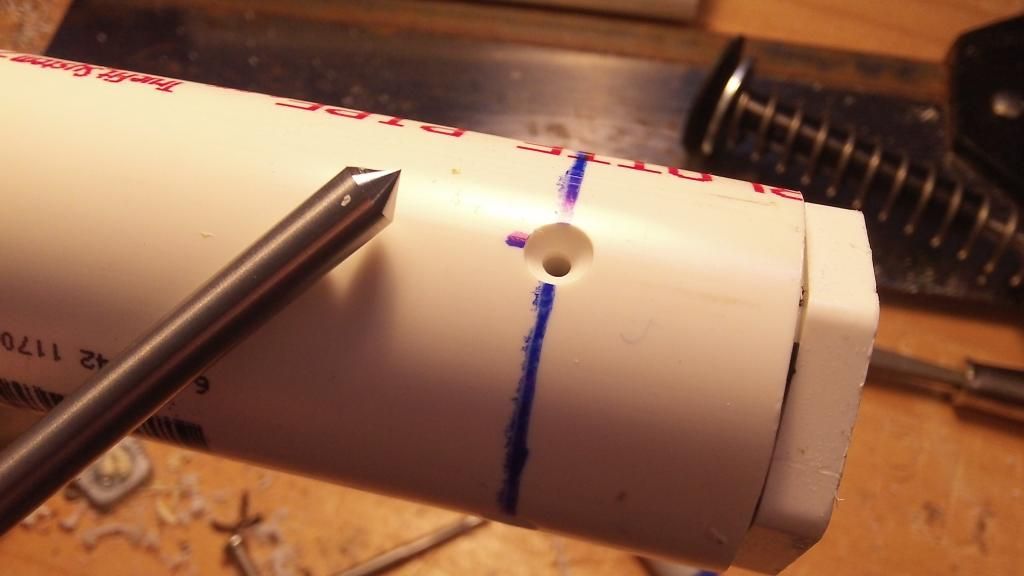

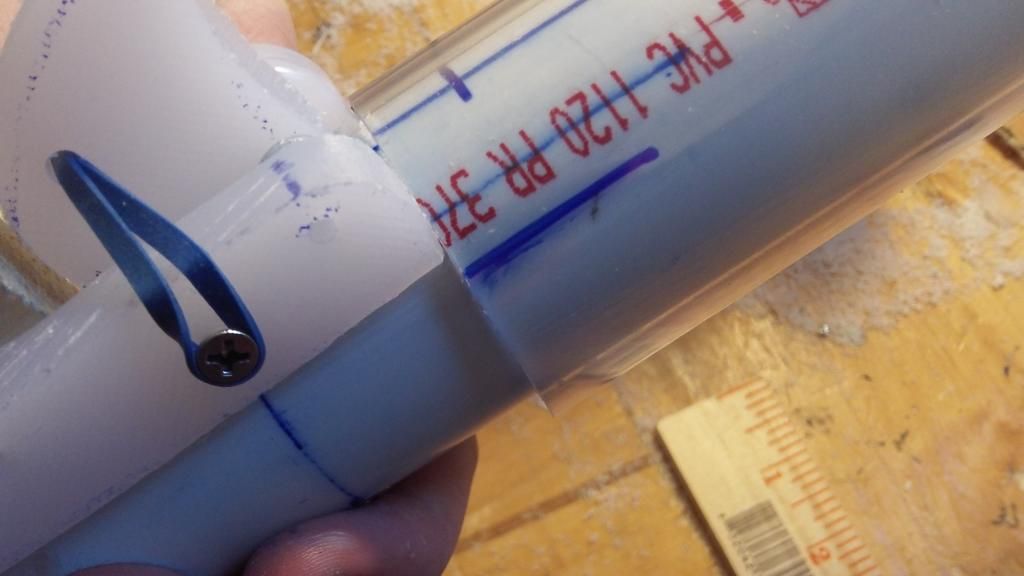

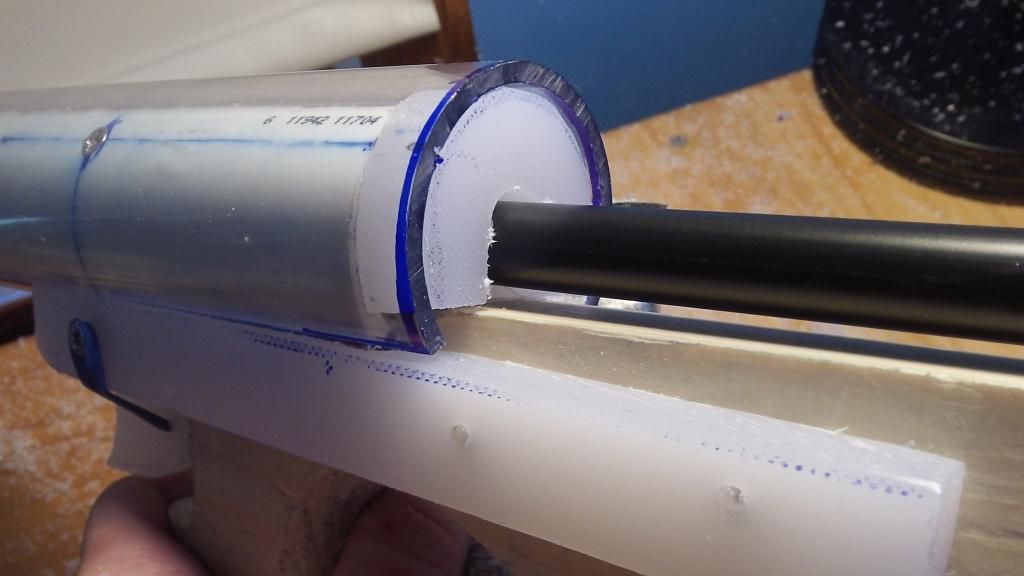

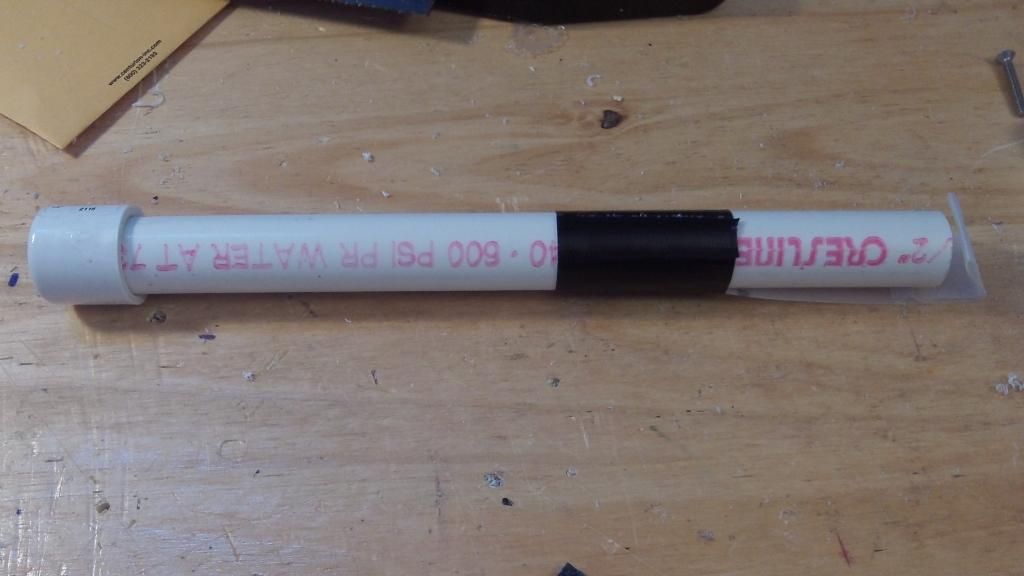

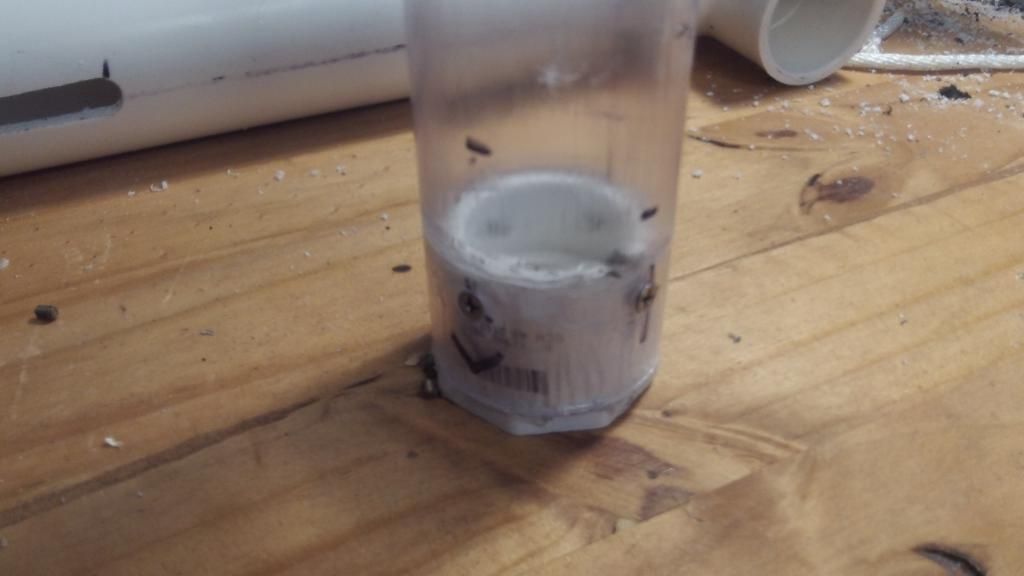

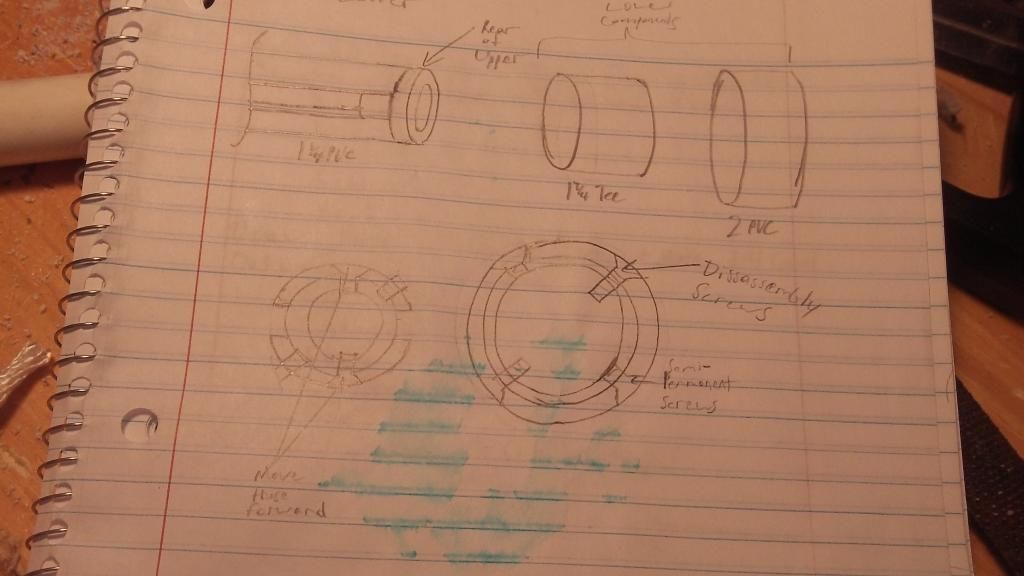

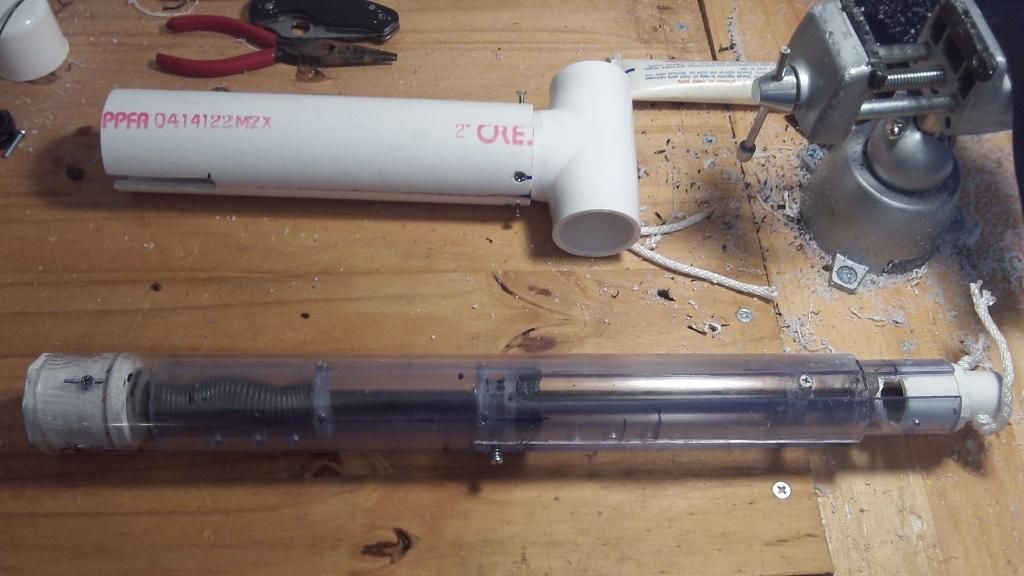

I'm going to be buying from you in a few days anyway so I don't mind at all. I'm told thinwall PVC is excellent for pumps. But I have NEVER seen it in any hardware store so typically I assume it doesn't exist for the sake of having a universally accepted writeup.

Posted by

Posted by