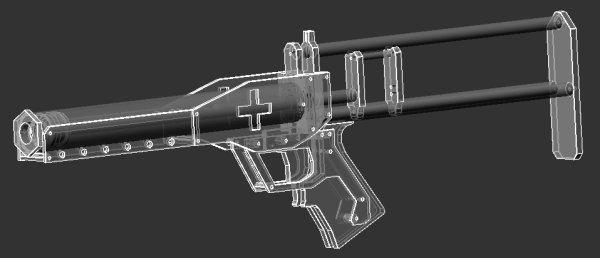

Like other projects before it, the +bow is an open source project for the benefit of the NIC.

In order to keep the original topic focused on the original design, this thread will instead be focused on the +bows that the community makes. Share photos of you guns, finished preferably, but mostly finished is fine too. Ask each other questions about what you did or did not do differently. That kind of thing. However if you are not making one right now or haven't finished one then there's no real reason for you to post in this thread.

It's not the easiest thing in the world to make and the amount of supplies needed is slightly higher than those of the FAR. So I'm expecting many of you will need some help or advice at some point.

Original Thread

Rev.3 Construction write-up Added July 4th, 2016

Rev.2 Construction write-up Added September 23rd, 2008

Rev.1 Construction write-up (Updated September 1st to revised trigger assembly photos and text)

Rev.1 Mirror version at Instructables

Rev.2 Autocad 2000 DWG for all of the parts that need to be cut from 1/8" thickness polycarbonate

Rev.2 Autocad 2000 DWG for all of the parts that need to be cut from 1/4" thickness polycarbonate

Rev.1 Autocad 2000 DWG for all of the parts that need to be cut from 1/8" thickness polycarbonate

Rev.1 Autocad 2000 DWG for all of the parts that need to be cut from 1/4" thickness polycarbonate

Rev.1 CAD files in Alibre Part and STEP 214 formats (700kb zip)

Here is the new plunger head:

It is part number 9562K46, with two 1.25" diameter polycarbonate circles, and 5/32" holes drilled in the centers. It is tightened heavily onto the rod, as there are small dimples in the front that need to be closed off by the front piece of polycarb.

To demonstrate the seal, the same test:

Edited by CaptainSlug, 04 July 2016 - 09:15 PM.