Most of this is just copied over from SonReeceSonJensen's SPANO 2013 post, so if some things don't totally make sense right now, that is why.

SPANO Twenty-Firtteen

Alright you filthy SOB’s, I’m locking this one in right now!

When:

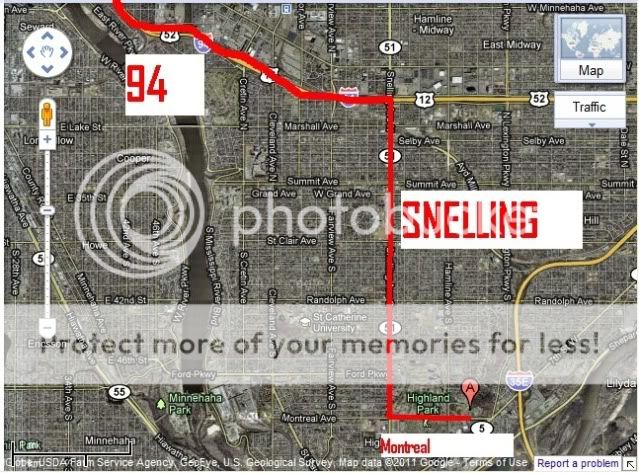

• Saturday June 21st. 9am to around 4pm.

Location:

• Highland Park in St. Paul, the classic location.

Games

• Meatgrinder

• Rescue the Princess/CTF: 2-sided, moshpit

• Defend The Core: 360 4-team, Dual-Opposite Criss-Cross, Traditional

• Territories: Small Territories/Pistols, HvZ Territories

• Carpe!

Blasters

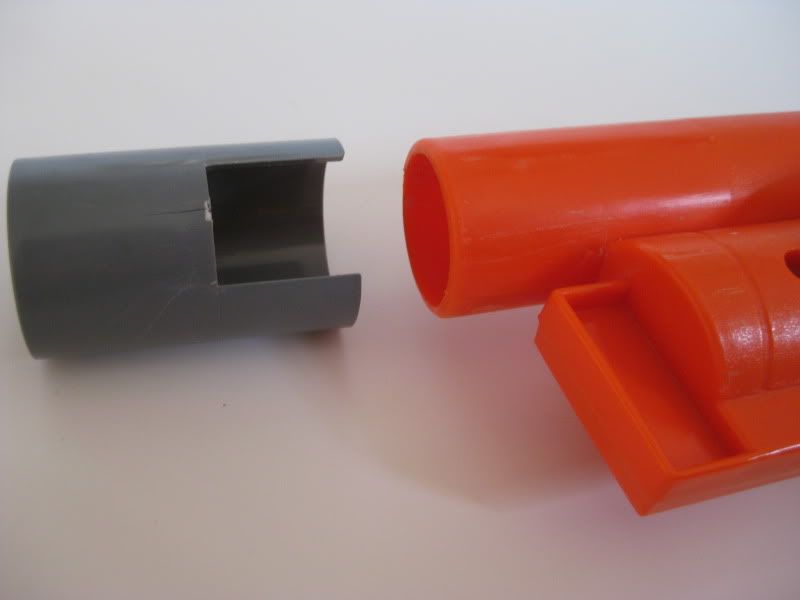

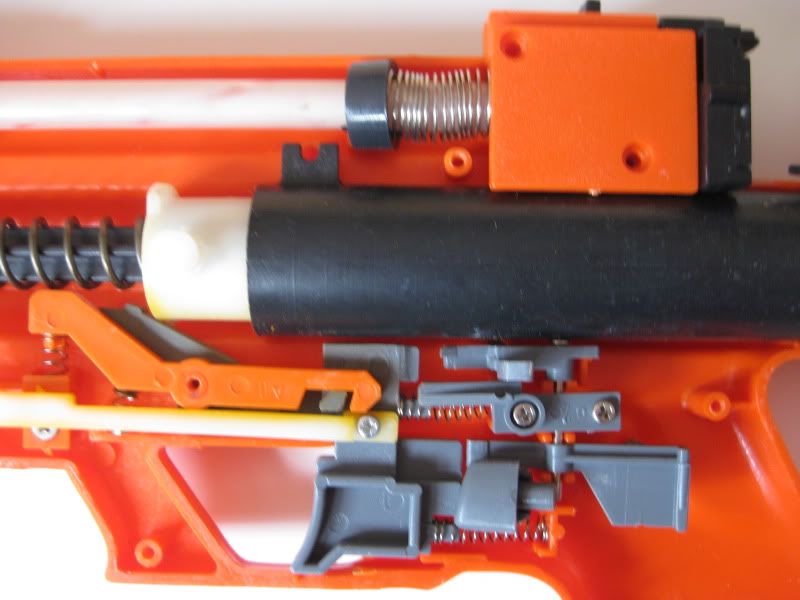

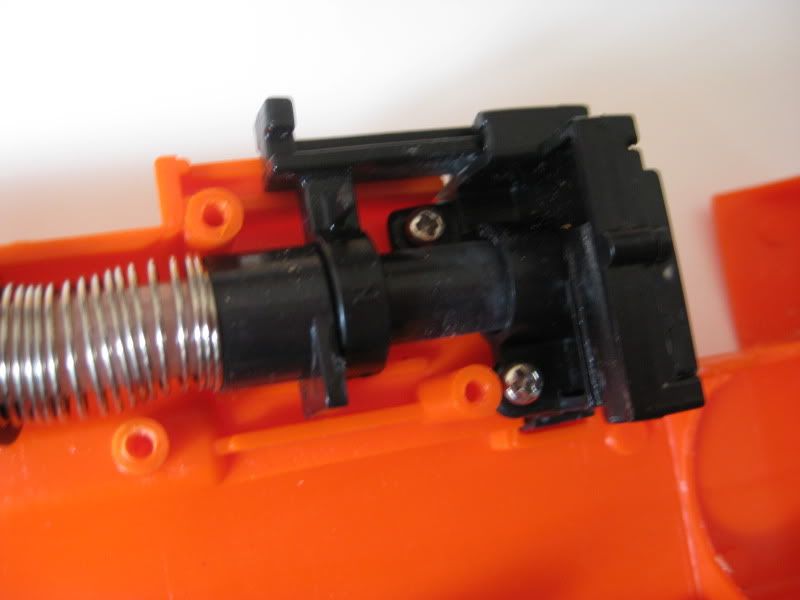

• Nothing single-shot bigger than a UMB with stock pump and oprv. No bans on springers/bow’ers.

• 4B’s, Titans, Jobars, Roto Rockets: ASK ME!!! Tell me you barrel set up and your intended ammo, I will be very fair if it is safe. No bans on blasters for big ammo.

Darts

• Slugs, Venom’s Balls, or ask me

• No glue domes

Melee Rules

• NO barrel taps

• Pool Noodle, FBR/foam insulator, crappy dollar store melee, or ask me

• No Nerf swords, nothing with a stiff shaft/core/center, nothing wrapped in duct

Shield Rules

• Mantas, manta replicas, ANY Nerf or toy blaster shell split manta style AND… ANY toy of ANY KIND cut up, hacked up, split up, I do not care as long as it is TOP MOUNTED on your blaster.

More Shield Rules

• Medium-ish hand-held toy shields and a pistol

• Bigish hand-held toy shields and melee. Look for pics of Cranky Monkey from Cataclysm 2012, you’ll know what I mean.

• Big Ammo counts as a ‘hit’, not a shield breaker

Pistols

• If you replaced the spring with anything other than another stock spring or the plunger tube with anything other than a different stock tube it is NOT a pistol. A SupaSplat and the like are NOT pistols.

Details

• Bring water. I’d advise not pop, not red bull, not sugar loaded crap: water is best but do what you like.

• Sunscreen: highly advised.

• 200 lbs of blasters and other materials: unnecessary. Bring what you need to play, what you need to trade, and maybe some things to show off.

Melee Rules

• NO barrel taps

• Pool Noodle, FBR/foam insulator, crappy dollar store melee, or ask me

• No Nerf swords, nothing with a stiff shaft/core/center, nothing wrapped in duct tape

360 DTC

Notes:

• Rounds will be no more than 10 minutes

• I know some of these aren’t nerf ammo: trust me, it does not lessen the game

360 DTC Point Gradients

• Stephens/Slugs – ZERO! Not a single damn point! Can still tag players, but no points.

• Stock ammo – 1

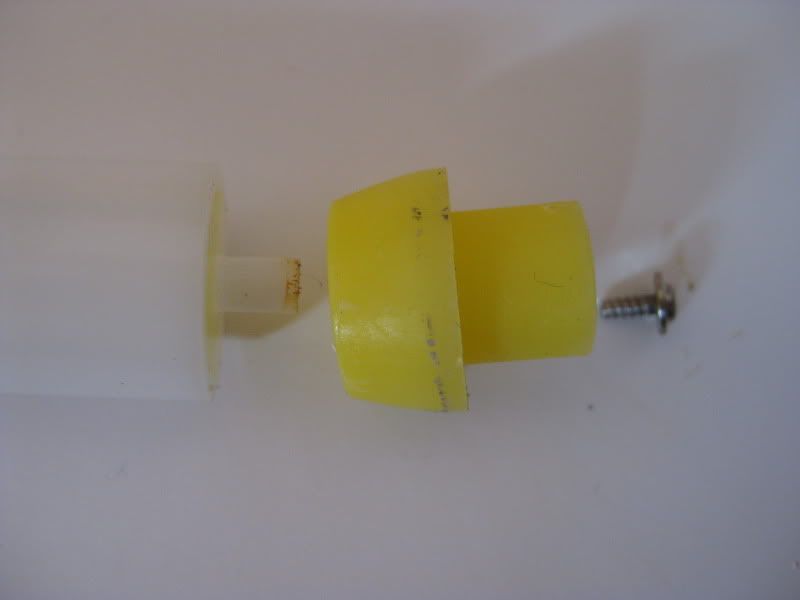

• Mongos/Ballistic Balls/Vortex discs or any disc ammo – 3

• Sock Grenades/Carpe balls/wiffle balls/ball pit balls (thrown) – 3

• Sonic Baz darts/Arrows/4B and UMB missiles – 5

• Stress Balls/small Nerf football/small plush toys (thrown) - 5

• Titan Rockets/Ironman Rockets/Draconas rockets – 10

• Homeade anything – Ask me, I will classify fairly

• Other crazy crap or weirdness - Ask me, I will classify fairly

Why I'm doing this - With these regulations we will maintain all the absurdly fun challenges involved as usual AND stretch our creative engineering to get higher points while NOT getting turned into pepperoni pizzas. And yes, if you want to stay on defensive whilst brandishing only melee you now can do it with a much high degree of safety and effectiveness.

HvZ Territories

HvZ Rules of Play

• 1-2 zombies at the start, rest are divided between 2 teams

• Humans and zombies are under blaster and dart regulations, see below

• If you are a human and are tagged by a human you are “dead”, and must remain in the spot you “died” in until a zombie resurrects you via touch

• Tagged zombies go to spawn points to re-enter the game

Objective

• Humans – claim every single territory

• Zombies – covert the filthy humans!

Blanket Regulations

• Stock ammo, silly ammo, or sock-grenades ONLY!

• No blaster more powerful than a Sonic Bazooka unless using sillies or multi-barreled.

• Zombies use only 2’ pool-noodle (I will provide some) or approved melee.

• Survivors get only one life, zombies are unlimited instant touch respawn.

[/quote]

Find content

Find content