A week or so back my nerf fabrication lifeline, my dremel, ceased to function properly. I got bit by the building/modification bug and had to find something to do that didn't require use of a dremel. So, after pondering some, I thought of revisiting the concept of rifling a nerf barrel. Is it even worth it and practical? Read through the following information to discover the answer. Just to mention, I have seen other threads similar to this, all with some flames. I am posting this in order to share my "experiment" and you can be the judge. On to the photos and stats:

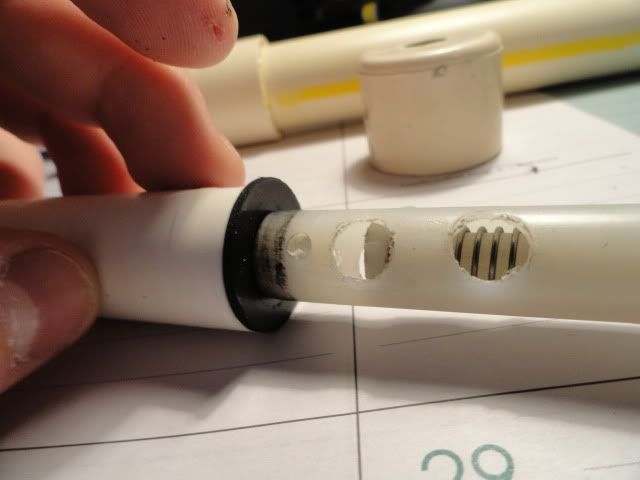

You may be asking, "How was this fabricated?", and let me say it is rather simple. The video I used to guide the construction of the rifling is THIS video. I used the method of wrapping three paper strips (only 2 sheets thick) around a rod that is slightly smaller that 1/2" cpvc using the method in the video link. I then added super glue along each strip, quickly slid over the cpvc, and let it dry. Once it dried, I cut off the excess portions of the strips and slid off the cpvc. There you have it, the simple method of rifling some cpvc for your nerf gun, but is it worth it?

Testing:

The rotation applied to the dart is about 1 rotation every 5 inches traveled. I tested the rifled barrel in a nitefinder with a [k26] spring replacement, coupler mod, and 4" cpvc barrel. Nothing too big, just enough to use for testing. I tried the barrel with 2 different darts, one weighted (slug dart) and one not (slug dart without the washer). During testing with a weighted dart, it achieved a small distance increase of about 5-10 feet more than the smooth bore cpvc barrel of equal size. I also fired the dart (80-87 degrees)upward in order to observe whether a spin was actually applied to the dart. This can be observed using this method because of the fact that the dart slows down as it gets higher, thus showing the spin. It also returned to the ground with a spin as well. To verify the spin I then tested the barrel with an unweighted dart. Unweighted darts go haywire and fly in unpredicatable paths when fired from normal smooth barrels, so it was a good area to test. Upon firing with the rifled barrel, the shot went directly forward. Though it did tumble at the end of its flight due to the lack of weight, it was the opposite of the smooth bore. The normal smooth bore cpvc barrel made the dart fly in a sporadic manner, with no predictability. If you would like to see a demo of the test with the unweighted dart, the link is THIS. For all of the tests performed, only one dart was used (one unweighted, one weighted) to eliminate a source of error. What are your thoughts on this? Your feedback is appreciated!

Note: The link about how to rifle paper barrels is from a hobbyist who makes replica rifles out of paper. I am not encouraging the use of pyrotechnics or replication or reel steel rifles in nerf. Plus, fire and paper probably aren't that fantastic of an idea.

-Ricochet

Find content

Find content