#26

Posted 28 January 2007 - 09:19 AM

#27

Posted 28 January 2007 - 10:25 AM

#28

Posted 28 January 2007 - 12:01 PM

I just have two questions, what’s the point of the tightening rings and where can I get them?

You just have to make them by crimping the brass slightly at certain points. As far as I know, there's nothing to be bought except for the brass.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#29

Posted 28 January 2007 - 01:46 PM

Could it work? Most likely though. My only beef is that the pump for the AT2K would most likely be external. Who knows I may just do it to my next Longshot.

SHA: A turret would be nice if a person integrated an AT2K into the front guns shell but I have a feeling it would look sloppy no matter how its done. Maybe Falcon can prove me wrong.

LNL king: Anybody can work around that with painting the pump. If someone integrated an entire AT2K into the longshots front gun so that only the black pump handle stuck out the bottom of the front of it then it would be worth it. I like integrations that are almost 100% concealed or they look like they should have been made that way.

Shadow 92: Just pick up a pair of pipe cutters at your local hardware store. Then tighten the pipe cutters on the pipe and go around the pipe for a few circles. If you do too much it will cut the pipe.

Well I found a replacement spring for my longshots second gun and it gets about 5'+ in range now.

I think I acquired this spring from that peice of shit of a transformers gun. Even after heavy modifications to the gun it could only get around 30 feet.

I am currently using a BB sized fishing weight for the darts for the front gun. I will try a single BB for BB guns next as I beleive the weight change will make difference.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#30

Posted 28 January 2007 - 01:52 PM

Paloose: I like the way the backup gun is a spring. I dont think I will be integrating an AT2K into it.

Could it work? Most likely though. My only beef is that the pump for the AT2K would most likely be external. Who knows I may just do it to my next Longshot.

Would it be possible to make the pump internal then use the grip it already has to pump the gun? It would look a lot cleaner, but it might require cutting down the pump and having more pumps due to a much smaller stroke.

#31

Posted 28 January 2007 - 08:22 PM

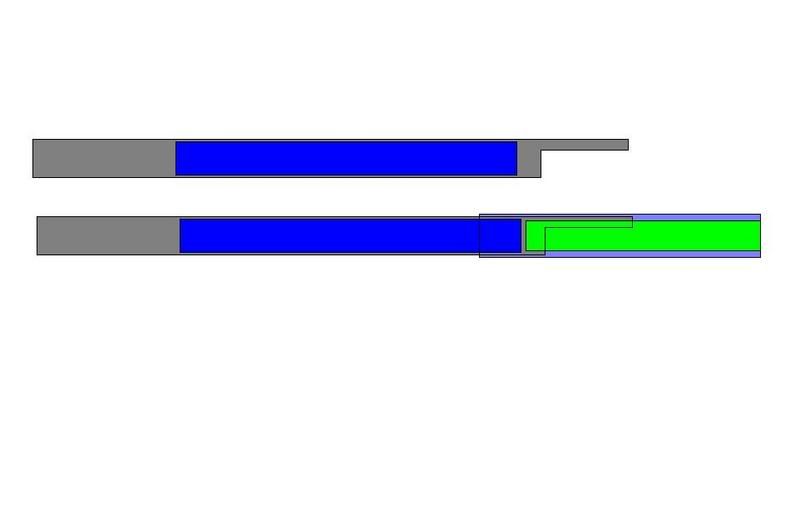

Here's my ten minute paint drawing of it.

The light gray is the 9/16, the blue is the 17/32, the green is the 1/2 and the other color is the 19/32.

Edited by Shadow 92, 28 January 2007 - 08:24 PM.

#32

Posted 28 January 2007 - 11:50 PM

Shadow 92: That should work but I think the 17/32" would be too long. The only problem I can see is the darts jamming because instead of squeezing into the 17/32" brass, the darts would bend at the center and bend outwards of the breech causing the breech to jam. This breech will jam if your darts dont slide into the tightened area. I had two chubbies that jammed like that. Red Fbr is yet to jam.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#33

Posted 29 January 2007 - 11:39 AM

My breech, inpired by Angels 3B

-Veg

Captain KLM, founder, modder and dartsmith of the Michigan Nerf Mafia.

#34

Posted 29 January 2007 - 08:38 PM

Nice, awesome everything. It's like that brass breech that I posted ages ago, but way better. Amazing.

My breech, inpired by Angels 3B

-Veg

Thanks, I never even saw this mod. If I did I probably would have come up with what I did about 2 months sooner. Thats so weird I am usually on here daily and I always click on the "view new posts". I really have no clue how that one slipped past me.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#35

Posted 04 February 2007 - 05:39 PM

To protect the paint I slid some felt craft sheet inbetween the longshot and the handle and then pulled out the flathead screwdriver. You should be pulling up on the cocking handle as you pry with a flathead at the same time.

I didn't chip any paint doing it this way.

Here is the stronger spring I added. On the right is the old stock spring.

Now that the stronger spring was in place I wanted to reinforce the nub that has broken off of at least 3 of my mavericks. I took some thin metal sheeting and bent it into shape then Gooped it in place.

I also added this squishy disc washer to the end of the shaft just ahead of the O-ring. I hollowed out the center and attached it with fishing glue. This doesnt act as another O-ring but acts more as some cushioning as the plunger was too small for me to add some foam rubber.

Now lets talk about the clips. I have seen some ugly LS clips after being modded. The plastic looks all white/warped or just plain missing where that glued nub used to be on the clip. The simple solution I have come up is to take a hobby knife or exacto knife and cut along the seam of the clip where the glue is. You may have to run the blade across it 5 or 6 times but its worth it. The picture should help clear things up.

So open your clip and add your rectangular bars to prevent the stefans from jamming in the clip and cut the follower just right. Then when you are done you can put back the two screws and just put a drip of superglue to run down the seam of the clip where the old super glue used to be and you have a clean looking modified clip.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#36

Posted 04 February 2007 - 07:02 PM

#37

Posted 04 February 2007 - 07:14 PM

#38

Posted 04 February 2007 - 07:37 PM

Retiate: My red darts have never jammed but some of my really chubby grey ones have in the breech. I am talking about darts going backwards in the clip and going to far back that they miss the breech opening so the clip system fails. The inventor guys clip mod fixed that but I have been using it all along. It is not new or exciting but I thought I should post how to cleanly open your LS clip without it looking messy.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#39

Posted 06 February 2007 - 01:01 PM

#40

Posted 06 February 2007 - 04:33 PM

#41

Posted 06 February 2007 - 04:48 PM

What tool did you use to make the tightening rings?

Standard pipe cutters. Just apply the pipe cutter blade to where you want the ring. Then tighten the pipe cutters then go around a few times. If you go too far you will actually cut right through the brass. So take your time on these. I have never unintentionally cut right through so it's not like high risk or anything.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#42

Posted 11 February 2007 - 08:15 PM

I really should reevaluate my Nerf carreer. I have been ultimated multiple times in a war, shot by a girl with an arced NF, and EMBARASSED by a 6 year old in quidditch on xbox. What am I doing with my life?

#43

Posted 11 February 2007 - 08:19 PM

Edited by Forsaken_angel24, 11 February 2007 - 08:20 PM.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#44

Posted 02 April 2007 - 03:37 PM

I glued mine using JB Weld two-part epoxy because it makes insanely strong bonds.

Still some work left to do.

Edited by CaptainSlug, 02 April 2007 - 03:39 PM.

#45

Posted 02 April 2007 - 08:41 PM

Your breech peice looks neater than Angel's but the other peice is clean too.

Next one who wants to be Michael Jackson, and save the world, gets a trip to Neverland.

Buy Boltsniper's guns!

Borrowed by FoamReaper of Boltsniper Forums.

#46

Posted 02 April 2007 - 10:28 PM

1. Yes. I'll make a thread on it when I'm further along.1. Is this the LS that you keep referring to as the crazy one that you are working on?

2. Your breech piece looks neater than Angel's but the other piece is clean too.

2. I have a wide selection of tools and a good deal of practice using all of them.

Edit: I just discovered that for temporary fitting and aligning of the barrel piece you can use 1/2" ID 1/16" diameter o-rings to shim between the brass and the stock barrel and receiver parts. You have to forceably wedge them in place but they provide a solid, yet temporary mount for testing the fit of all of the parts together. It's particularly helpful when gluing the hardpoint on the bolt piece.

Edited by CaptainSlug, 02 April 2007 - 10:53 PM.

#47

Posted 03 April 2007 - 12:42 AM

Distance fomr orange disc to cut 1.09"

For the brass that sits inside the nub that was the bolt.

2" of 9/16" brass.

2" of 17/32" brass that fits inside the 9/16"

The main barrel of 9/16" is cut at the end so 2.25" is a half pipe. This half pipe will be receiveing the darts.

The 19/32" brass that slides over the 2" 9/16" brass is 3.75"

The 1/2" brass that pushes the stefan dart forward into the tightening rings is 4.5 inches.

All these measurements should be fairly accurate. You may need to cut a little bit extra off here and there.

I have more for the longshot but I hope this helps some people for now.

Oh be sure to lube the top half of the half pipe of the main barrel. This helps the sliding of the 19/32" and makes cocking the gun and shotgunning darts alot easier.

Edited by Forsaken_angel24, 17 September 2009 - 11:38 PM.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#48

Posted 06 April 2007 - 11:50 AM

Edited by Prometheus, 06 April 2007 - 11:54 AM.

#49

Posted 06 April 2007 - 12:57 PM

No, you are limited by the stroke length of the bolt mechanism itself which is roughly 3-1/2 inches.Do you think there is anyway to lengthen the breech opening, so longer darts/two darts at once can be accepted?

#50

Posted 10 April 2007 - 06:18 PM

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users