Your responses are helpful but I most of them are things I know.

Carbon, I am going to use a .75" endcap like the one in your SNAP if lubing my current set up doesn't work. It will have wiggle room if yours did because I have a 1.25" body/plunger tube and a 1.5" rubber washer just like you. And since my plunger is inserted through the front of the gun, the washer cups forward and doesn't let any air past it. No loss of air around the plunger head at all. That might be slowing it down so I'm gonna lube everything up real nice. I know I need to because I don't even have to have the front of the plunger tube plugged to slow or stop the plunger, it is slow all by itself.

And the spring I'm using, FH, is of course the AR spring that Boltsniper uses. It is half of the spring and is longer than it needs to be to make sure that it gives enough force. I think the spring is strong enough so I don't need any other kind.

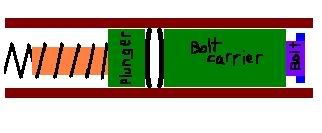

Promy, I was going to do the longer 1" section but now I'm just switching to the endcap plunger head. And the bolt carrier doesn't have a seal behind it yet because I haven't decided on how I want to attach it (another 1.5" rubber washer with the inner hole made bigger for air flow). Maybe nail it, screw it, or glue it. I prefer the first two so that it can be replaced but I don't think making holes in the carrier would be a good idea. And I don't think that the slightest of space between the outside of the carrier (1" thin PVC) and the inside of the body/plunger tube (1.25" PVC) is enough to lose all pressure made by the plunger.

And if all fails, I'm going to have to change to O-rings. I really don't want to.

I have to take pictures of my stuff today for my presentation and lab report so you guys will probably see them by the end of tonight. And my SketchUp design which is mostly complete to the functional level (I only have the barrel, bolt, shell, and general shape of the body and receiver of the shotgun).

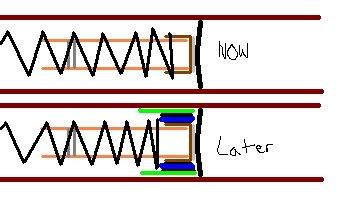

EDIT: I tried more lube and the first shot got half way through the barrel. Then, I super lubed it and the dart only moved an inch down the barrel, don't know why. Finally, I added a few layers of electrical tape around the back of the bolt carrier for a temporary seal and the stefan went 30 feet! Yes!

I know that it isn't much but with the improved plunger and carrier seal (neither will be done today, I think) I can improve the range to a much more acceptable one. And with the rate of fire that comes with pump-actions, it will be great.

Then, when I got 30 feet I showed my little brother the whole process of loading for now (about 45 seconds long) and shot it. The gun embarrassed me and I found out that the stefan got out of the 12" brass barrel but stopped in the barrel sheath, the .75" thin-wall PVC. I also found that it was because for some reason the stefan got chubbier and was harder to fit into the shell and it was the same stefan that I used for the previous three shots.

At first, the first time I ever shot it (Friday), I did put lube on the plunger head but not in the tube. And on the head I only used a slightly lube paper towel and wiped it on the rubber washer. Definitely not enough, but I didn't want to make the gun so messy.

I might be going to Lowe's to buy the endcap to replace the plunger head today but I doubt I will get it onto the plunger.

Still gotta take those pictures, though.

Edited by Commonly Hunted, 09 April 2007 - 08:51 PM.

This topic is locked

This topic is locked