#26

Posted 27 October 2006 - 09:00 PM

So, yes, I am making the halo 2 shotgun.

It really doesn't seem that hard after I looked it over. I plan to use some of Boltsnipers diameters and such for the plunger and whatnot. That's a road I have never gone done, and I want it to be thin enough for you to be able to handle it...I hate guns that you ahve to man-handle like the titan or something.

Other than that, I do have a spring that I want to try out when I get to that step, and as far as PVC goes, I am sure I have something to surfice around here.

Darts sizes will be anything from 1.5 to 2 inches long. If I make the hole in the breech 2 inchs, you would get 2, 1 inch long darts in there, and that would throw the gun off some.

Updates on the beam rifle also. I have the parts drawn into the gun, and I am now working on the design on the side of the gun. Barrel will be 24 inches of 1/2 inch CPVC, and since it will be powered by a blasde paintball gun, I need to get some ranges. So, if someone happens to have one of those modded and is willing to maybe put a 2 foot barrel and give me some specs, that would be good. I don't want to waste my time by having to change the design on the gun to fit the barrel length. The LCD panel off the camera is fried, so I need to track down a real cheap LCD camera.

#27

Posted 27 October 2006 - 09:08 PM

So, yes, I am making the halo 2 shotgun. - LastManAlive

That Halo 2 shotgun concept seems like it might fit my plan right down to the sights. If you come across any advantages or problems in the design, PM me or post them here.

Edited by SHADOW HUNTER ALPHA, 27 October 2006 - 09:08 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#28

Posted 28 October 2006 - 07:31 AM

Like I said, after looking the gun over int he Halo 2 instrution booklet, it would fit my design with a breech perfectly.

If you haven't seen the gun yet thoroughly, I suggest you do. Otherwise you will be lost.

But if you look at the placement of the pump, you can see that it just bellow the barrel and would be inline with a spring mech. So, all I really need to do is make a homemede springer with a brass breech and point the breech upwards for the top loading system. Pull pump back, cock gun, and open breech.

This also allows room for the idea I had of actually loading the gun. I planed to make the little trigular shaped peice in the resiviour spring loaded, and actually be able to push it down (if on a top loading shotgun) to be able to side more darts in. The only disadvantage I have to that, is that you could jam some of the darts already inside the resiviour when loading. So, I would need a carry rod sticking through the resiviour to push the spring forward while the gun is tilted down. This allowing the darts to grtavel back down the resiviour and prevent jamming. It sucks though, because for those insanely tactical situation when the adriniline is pumping, you just want to cock the gun up on your leg while you rest against a tree like in some video game.

However, your system would be ideal for that. If you use shells, you wouldn't have the hassle of them getting jamed in the resiviour. You also won't have the hassle of what sized darts go in the gun. You could make 3 inch long shells, and still fire shotgun, 1 inch, 2 inch, and 3 inch stefans. But that brings me back to my design where it will be kept simple with the breech being operated by the pump itself, and not having to worry about an ejection port. So, I think we can both agree that we have advantages and disadvantages to our comcepts, but none-the-less I am more enthusiastic about doing this now.

So onto my plans for designs. Like I said, I haven't had time in drafting class to draw up the Blade PB gun powered Particle Beam RIfle yet, much less get this stuff on an organized sheet of paper. While on the other side of the project, my friend will be giving me a Blade PB gun that just needs a repari on the CO2 cap and his father has already got loads of fiberglass sheets for us to start on any of our porjects. I have barrel materials all down to just getting one more foot of 9/16s for the breech on the shotty, and I have a trial spring I want to test whenever I decide to throw a mech together.

#29

Posted 28 October 2006 - 10:46 AM

Sounds like someone has done his homework. I agree that both of our concepts have some flaws, and there's no getting around that. My carrier and bolt designs are going to be pains in the ass to build, since I haven't seen anyone do this kind of thing before. Your gravity feed is also going to have a lot of problems with jamming in an intense firefight. However, I think that a lot of the problems in our systems can be worked out through trial and error if we both contriibute to each other's designs. It would also help to see some other readers contribute ideas based on their experience as well. Hopefully, some of my parts will be compatible with parts or upgrades you may be developing after or during your project.

Edited by SHADOW HUNTER ALPHA, 28 October 2006 - 08:03 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#30

Posted 28 October 2006 - 09:21 PM

But hey, if we're all in this together.

My variation of LastManAlive's shotty is hard to explain, but basically the breach is going to pop up (like one removeable shell) as you cock back, you'll put the dart(s) in the back of the breach, and then it'll close as you pump forward. I've actually figured it to be quite a simple concept, and since you're always loading from the rearmost section of the barrel, you won't have to worry about jams.

I would like to help but am a little confused (I seem to be good at that lately... sorry): How exactly would yours jam? I know that it's going to be grav-fed, are you going to attach a clip?

As for SHA's shotty variation... uhm... well... it's a secret. I'm not really sure there's a major problem with it being "a pain in the a$$ to build," because so was BS's FAR but that turned out frickin' sweet. Something to look forward to, anyone?

...and ideas are bulletproof. "

#31

Posted 29 October 2006 - 09:14 AM

It sounds like the shotgun you want to build will be a break-open breech type weapon. If that is indeed what you are doing, then you probably do not need or want a pump. Shotguns and other weapons that use pumps have a solid frame, where the cycling rod can be directly attached to both the pump and the bolt. Break-open shotguns are only connected at one point: the hinge. this means that there will be no way to effectively attach a pump while still having it [the pump] serve a useful purpose. Since my design has a rigid frame, a pump would be the most beneficial. For breech-loaders, you can either manually cock the weapon with a charging handle, or you can find some way to make the two hinged halves of the gun cock the weapon as they fold back together.

My own gun will probably have some tight fits with the carrier, but that should be the only real problem. As far as I know, I'm the first one here to ever use a carrier, so it looks like I might have to pioneer some fabrication techniques. However, when I get the gun finished, it should definitely be something to look forward to.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#32

Posted 29 October 2006 - 09:55 AM

If it were gravity fed, then my deisng would have no use to it. Nothing new.

I am aiming for making the first tube-like loading system. It will be horizontal, with the rest of the gun.

So as for jamming, if I put 1/2 inch stefans in it and I have a 2 inch breech hole, I'll have 8 stefans in the gun. So now, if I have a 2 inch breech hole, and I put 1.5 inch stefans in the gun, I will have one whole dart, and the other dart will get jammed between the breech and the loading sytem.

But on his design, he will be using shells. Thus, he can put a 1 inch stefans in a 2 inch shell that fits a 2 inch hole, and he will be good to go.

Edit: I know it sounds comfusing, but if I get time this week in class, I will try and get a pic of the shotty done. Unless, I have time, it will be without a design for the trigger and all that. But again, I will be using a paper clip trigger mech. So, it will be simple.

Edited by LastManAlive, 29 October 2006 - 06:02 PM.

#33

Posted 29 October 2006 - 12:41 PM

I looked over your post again and realized that I mixed up the word "travel" with "gravitate" because there is a typo there. However, there is still a problem with your design. The size of your dart and the size of the breech can be perfectly identical, but if the edge of another dart even gets caught between the rim of the breech and the loading system, you are going to have some major problems with the firing because now there is a bent-up dart that prevents the breech from closing and getting a good seal. That either means that you can't fire, or the pressure that is lost while firing is too little to propel the dart out of the barrel.

Also, I don't know whether you are going to make a true breech-loader or a magazine-fed shotgun, because they are definitely not the same things. PM me a picture and I might be able to understand and help you.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#34

Posted 29 October 2006 - 01:04 PM

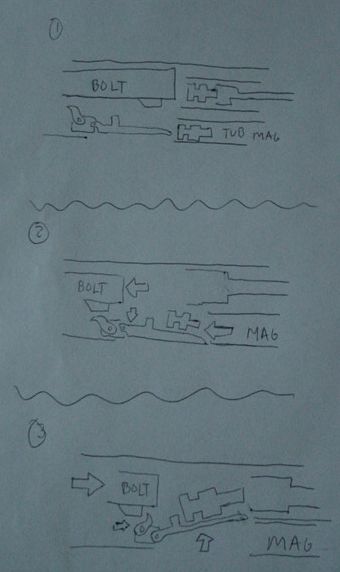

1st diagram:

This is at a stand still. The bolt rests above the carrier mech with a shell in the chamber.

2nd digram:

As the bolt moves back and the spent shell is ejected, a lip on the bottom of the bolt pushes down on the carrier dog, turning several gears* to allow the carrier to move down to allow a shell onto the carrier.

* The gears would allow for when the carrier dog is depressed forward, the carrier is then lifted upward.

3rd diagram:

As the bolt moves back forward, the lip engages on the carrier dog once more in the opposite direction, forward, and the carrier is then lifted upward through a series of gears in the carrier mech.

The bolt moves forward and catches the shell and moves it into the chamber. The carrier dog is then released from the lip-catch and falls back to the stand still position, as with the carrier.

The hard part would be to fabricate the carrier, carrier dog, and the gear mech to allow it all to work in-synch.

#35

Posted 29 October 2006 - 01:20 PM

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#36

Posted 29 October 2006 - 02:57 PM

It sounds like the shotgun you want to build will be a break-open breech type weapon.

LMA's Variation: No... it's hard to explain. I am going to have one shell that will pop up as you cock back, you'll put a dart in the back, and then the shell will go back in as you pump forward. It's not a break-open. It's kind of like a Beretta breach (remember when Cartoon posted that?), but only part of the barrel has to open up, not the entire section that's in front of the breach.

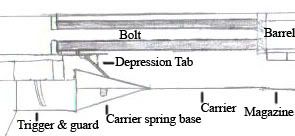

SHA's Variation: Still waiting for a rather large sketch of that depression tab... here's what I was thinking:

The bold arrow points to a spring inside the piece which attaches the pump to the depression tab, this spring makes it so the pump will depress the tab enough but won't break it when it has to go farther in order to cock the gun.

...and ideas are bulletproof. "

#37

Posted 29 October 2006 - 04:36 PM

All of the major parts have been labeled so there's no confusion. The depression tab is indicated, and the vertical line connecting it to the bolt is the spring. In the carrier spring base, the U-shaped gray thing is the carrier spring, fully compressed. I'm sorry that there's little defenition between the carrier and the bottom of the magazine, but the carrier ends where the bolt and barrel meet. That should give you a general idea.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#38

Posted 29 October 2006 - 09:58 PM

Also, I'm still unsure as to how we're going to keep shells from A) slipping under the carrier, B ) pressurizing the carrier (through the mag spring) enough so that it can't be moved.

Thanks for tolerating me.

...and ideas are bulletproof. "

#39

Posted 30 October 2006 - 04:45 PM

To address the problem of shells slipping out under the carrier, I plan to make a small spring-loaded tab that will be able to fold in towards the magazine to load a shell, but not out when the shells try to fly out from under the carrier. Also, the space for the carrier to hold the shells will be limited to exactly 1 shell and no fractions above or under that. To stop the shells from loading themselves onto the carrier and preventing the carrier from being pushed up to load more shells into the magazine, I might have to design some type of catch on the mag. tube that you flip and it blocks off the shells. I will probably try something else, though, because that seems like it might take way too long to load this thing if I use that idea. (I'd have to flip the catch up and down for every shell I load.)

If you have any other problems or solutions, then tell me.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#40

Posted 30 October 2006 - 04:55 PM

I will see what I can do with 2000 LT.

#41

Posted 30 October 2006 - 05:12 PM

Edited by SHADOW HUNTER ALPHA, 30 October 2006 - 05:14 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#42

Posted 30 October 2006 - 06:17 PM

keep posting guys. Your questions are making quite a difference in my design.

Sweet! *thinks of a new batch of questions*

Goshdangit I still have no idea how it works. I think this is more just my personal level of intelligence, but still... something about this just doesn't make sense to me:

I'm sorry, but I still just don't see any logical way that can happen (dog down, carrier up) without the inclusion of something not pictured.

I understood all the words in your explanation (even the big ones like hypotenuese

One problem I see is that if the bolt and tab are connected, then the shell won't get stripped from the carrier until after the carrier goes down (in which case, it won't be in place to be stripped). Step 9 shows how the bolt lets go of the dog just after it strips the shell. If the tab and bolt are connected, I don't see any way the bolt can be out of the way for the shell to move up on the way back and still strip the shell before the shell drops down on the way forward.

Thanks again for answering all my questions.

...and ideas are bulletproof. "

#43

Posted 30 October 2006 - 09:54 PM

I'll definitely try to get some bigger pics up sometime in the next 2-3 days.

Now, about that depression tab issue. I thought about exactly the same problem you did, that the depression tab would come down too soon and the carrier would go down before the bolt could load the next shell. But then, I remembered that I'm using a rotating bolt. This means that if I shorten the tab just a little bit and place it at a point on the bolt where it will be timed to release only after the shell has been loaded, then the problem should be solved. Then again, this is all just speculation, since I haven't made a model or gotten into all of the mechanics just yet. If I post a way bigger detail view up here, then I might be able to talk to you guys about the really fine details of it all. I only wish that boltsniper could post something here, since he's actually built a rotating bolt before and he could give me some insight as to what I might need to do here.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#44

Posted 30 October 2006 - 10:16 PM

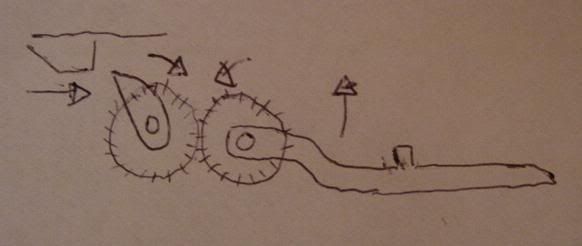

It would reall only need two. (See below)...and it's so much easier to fabricate that a PVC box of like 12 little gears that probably get messed up when you drop the gun.

I'm sorry, but I still just don't see any logical way that can happen (dog down, carrier up) without the inclusion of something not pictured.

Wham!

You only really need two gears to make it work.

As the bolt moved forward, the lip engages on the dog moving it down forward.

Then, the dog gear moving clockwise would turn the carrier gear counter-clockwise, moving the carrier up. It's really simple.

You guys, if you have access to a real pump-shotgun, take the chance to look!

It's helped me quite a bit. Although the one I looked at was completely different; the dog and the carrier were connected and it was really weird... But, it still worked. Replicating actually working designs is a whole lot safer then replicating designs that make no sense, coughhowstuffworkscough.

To address the problem of shells slipping out under the carrier, I plan to make a small spring-loaded tab that will be able to fold in towards the magazine to load a shell, but not out when the shells try to fly out from under the carrier. Also, the space for the carrier to hold the shells will be limited to exactly 1 shell and no fractions above or under that. To stop the shells from loading themselves onto the carrier and preventing the carrier from being pushed up to load more shells into the magazine, I might have to design some type of catch on the mag. tube that you flip and it blocks off the shells. I will probably try something else, though, because that seems like it might take way too long to load this thing if I use that idea. (I'd have to flip the catch up and down for every shell I load.)

My idea:

Go look at a double shot and look at how the shell stays in.

Look at the white thing holding the shell in place.

If you could replicate that to where it holds the shell in place 'till the bolt is in the rest postion, interacting with the catch allowing a new shell to pass.

Just my idea.

Ninja.

#45

Posted 31 October 2006 - 09:29 AM

All the same, a good idea...

...and ideas are bulletproof. "

#46

Posted 31 October 2006 - 03:11 PM

1: If the carrier and carrier dog are connected like that, then how does the entire system move when the carrier is raised? I know the carrier dog moves, but it seems like it would have to move towards the carrier to raise it, based on your picture.

2: Where am I going to find a set of gears that small and how am I going to keep them in place should the gun be dropped?

3: How would I solve the problem of a jam (I.e. a locked gear) without dismantling the entire receiver?

Even though I don't know the answers to these questions, I will probably switch over to the carrier dog system instead of my depression tab. That way I have a proven system and don't have to worry about springs or very strenuous pressures on the sides of the bolt and carrier. I'm not discounting Flaming Hilt's arguments, but I might be able to pull this one off more easily than the depression tab. I guess this means I'll need to draw more pics, but still, thank God for Ronster.

Edited by SHADOW HUNTER ALPHA, 31 October 2006 - 03:13 PM.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#47

Posted 31 October 2006 - 06:05 PM

1) It does move towards the carrier. Go to howstuffworks.com again, you'll find that the bolt pushes the dog forward and releases it just after the shell is caught.

2.2) You keep them in place using aluminum rods (or something else very sturdy) as axels. Honestly, I've dropped many of my guns but as long as materials are good and construction is sound, they hold up. Use good materials and secure them well.

3) First, you have to keep your gun clean. This means not dropping it in the mud and maybe taking it apart for cleaning every now and then. This is, of course, what you do anyways for the rest of your guns -- except for O-rings and valves, not gear. No big change. Either way, I'd rec'd making the reciever attached to nothing on the gun, so it can easily be removed and the internals cleaned.

And yes, Ronster... is a genius.

2.1) This is what's gunna pull us down. Either we gotta make 'em, or... who knows where we're gunna buy 'em. Maybe we could fiberglass reinforce Legos...

EDIT: This guy seems to have plenty of gears.... Brass and $3/gear.

Edited by Flaming Hilt, 31 October 2006 - 06:13 PM.

...and ideas are bulletproof. "

#48

Posted 31 October 2006 - 06:27 PM

I forgot that the carrier dog does indeed move towards the magazine. Noob mistake #654 - overlooking simplistics. As for the axles, I was thinking some thin music wire or a really skinny nail, something that won't bend or crack easily. I intend to clean and lubricate this gun well, so your 3rd suggestion won't be a problem. As for the gears, I think it would be easier to find some at a hobby store or something, since I'm not paying $3 for a single gear. (and I have yet to see a round, gear-like Lego.)

With these problems mostly solved, I need some suggestions on how to prevent the shells in the magazine from slipping out of the gap when the carrier is raised to load a shell. I have a feeling that my spring-loaded tab on the end of the carrier might not work since it will be too big.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

#49

Posted 31 October 2006 - 06:41 PM

I am still hesitant about using gears. It seems like a lot of work. Getting the right sizes (so moving the tab x moves the carrier y -- number of teeth), getting them in place, getting them on axels and getting the tab and carrier attached. Then, say you put it too far back... you have to do it all over again.

And then say it still doesn't work, for any reason. All that for nothing. It's a good idea, but I'm just not sure it's worth it. Pulleys, maybe (same concept, a lot less work)?

P.S: Never seen a Lego gear? Uhm... the Technic sets are based almost entirely off of gears and shafts.

...and ideas are bulletproof. "

#50

Posted 31 October 2006 - 07:35 PM

I still don't get that slide - breech thing. Maybe you should draw a sketch like Ronster or give me a web page with an example. I do better with visuals.

Founder of the Shadow Militia.

Founder of Nightshade Laboratories and The Nightshade Armament Corporation.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked