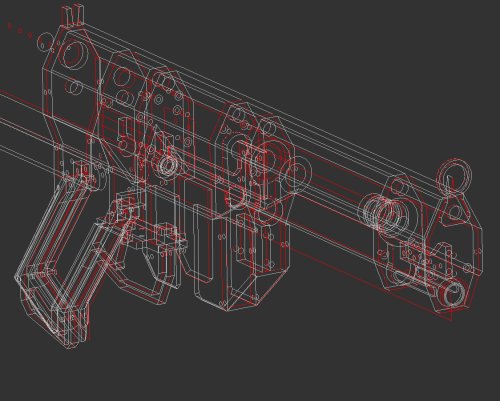

Model is completed.

And the part list and cutting list are both made.

Posted 28 May 2007 - 08:03 PM

Posted 28 May 2007 - 08:09 PM

Posted 28 May 2007 - 08:21 PM

Edited by CaptainSlug, 28 May 2007 - 08:26 PM.

Posted 28 May 2007 - 08:43 PM

Posted 28 May 2007 - 08:48 PM

Dunno if this was asked. Since it needs an external air source to operate, will you be making any tanks and the such to be specifically used/mounted on this?

Posted 29 May 2007 - 09:05 AM

No. But since the design empties only the air pressurized in the breech actuator, if you were to put an extremely basic tank inbetween the bike pump and the gun it would afford you multiple shots from a single cycle of pumping. But the pumping cycle would obviously take longer since you would have more volume to pressurize.Dunno if this was asked. Since it needs an external air source to operate, will you be making any tanks and the such to be specifically used/mounted on this?

Posted 29 May 2007 - 02:44 PM

Posted 29 May 2007 - 03:41 PM

Posted 29 May 2007 - 04:03 PM

Posted 29 May 2007 - 05:47 PM

I hope so. But no guarantees.Do you think you'll have a prototype of this by DCNO?

It's outlined in the machining guide. You make an image from the printscreen and then paste the image on a page in Microsoft Word. Change the image dimensions in Word to match the dimensions of the part from the CAD file and you end up with a 1:1 template. I cut out all the parts to square dimensions using the tablesaw first then follow the template as a guide for drill and cutting to make the rest of the detail.Those templates look very promising. But I've always wondered... How to you get the picture from Alibre to be the exact size of what you want when you print it out?

Edited by CaptainSlug, 29 May 2007 - 05:48 PM.

Posted 29 May 2007 - 05:52 PM

Posted 29 May 2007 - 05:57 PM

Edited by CaptainSlug, 29 May 2007 - 06:10 PM.

Posted 29 May 2007 - 06:04 PM

Posted 29 May 2007 - 06:10 PM

Edited by CaptainSlug, 29 May 2007 - 06:25 PM.

Posted 29 May 2007 - 06:16 PM

Edited by Ronster, 29 May 2007 - 06:21 PM.

Posted 29 May 2007 - 11:04 PM

Posted 29 May 2007 - 11:53 PM

1. 3-7/16"1. What is the stroke length for the breech?

2. Will mags have to be Stefan modded, or streamline compatible?

3. Also, looks like a tiny valve for the gun, which is always a huge challenge for any homemade compressed air gun.

Edited by CaptainSlug, 04 June 2007 - 08:40 AM.

Posted 30 May 2007 - 06:41 PM

Posted 30 May 2007 - 06:45 PM

Edited by CaptainSlug, 30 May 2007 - 06:52 PM.

Posted 30 May 2007 - 06:59 PM

Posted 02 June 2007 - 07:20 PM

Edited by CaptainSlug, 02 June 2007 - 07:59 PM.

Posted 02 June 2007 - 08:42 PM

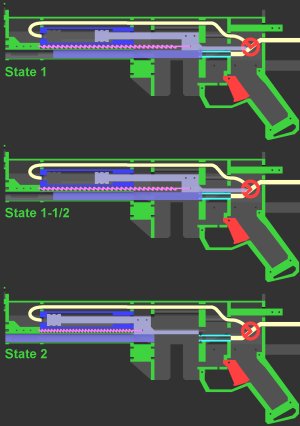

The air cylinder and breech are actuated together at a rather low pressure level (around 6psi presumably) but will be filled to at least 20psi.

The pressure level inside the air cylinder will not be able to drop far enough for the breech to actuate forward until the dart has left the barrel. The spring can then pull the breech forward to chamber the next dart.

For finer adjustments to the timing I can later adjust the pull strength of the extensions springs.

Directional control valves start around $14 and the price increases based on the number of ports, what kind of tripping arm is added and what pressure level it operates at.

Posted 02 June 2007 - 08:45 PM

Edited by CaptainSlug, 02 June 2007 - 08:46 PM.

Posted 03 June 2007 - 12:26 AM

The forward attachment point for the extension spring has 4 tension settings if adjustments are needed.

Well, I may not be able to finish this gun before DCNO unless I can earn some more money outside of what I've been trying to save up before my trip to China. I'm going to have to order 1/4" thickness polycarbonate because the scrap at the machine shop is most likely going to be in metric sizes.

Hmmmmm

Posted 03 June 2007 - 01:04 AM

Edited by CaptainSlug, 03 June 2007 - 07:53 PM.

0 members, 1 guests, 0 anonymous users