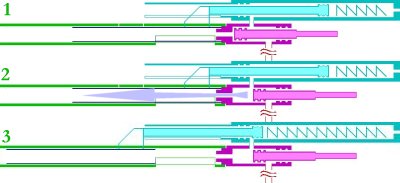

A Pulse-Width Modulation circuit will be needed to control the cycling of the solenoid which will trigger the valve. The valve is spaced so that each cycle will equalize the charge tank with the main tank, the charge tank will seal, the breech-actuator will close the breech, and then the dart will fire. And the reverse will let a new dart chamber.

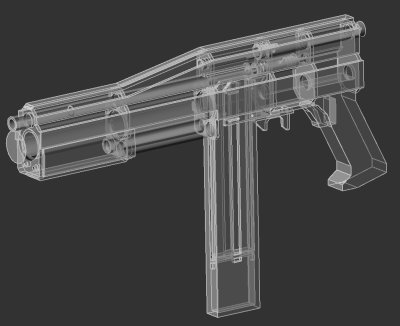

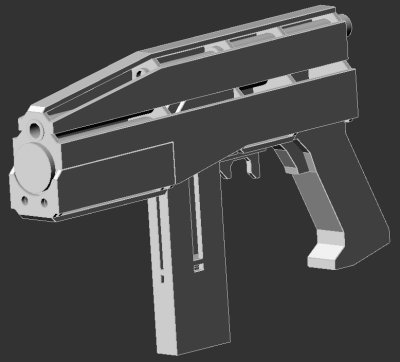

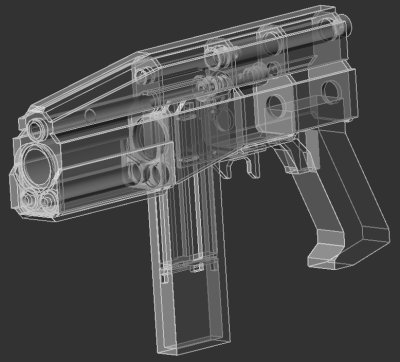

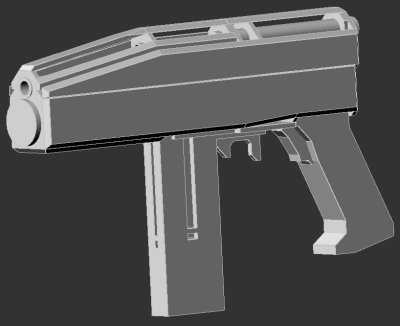

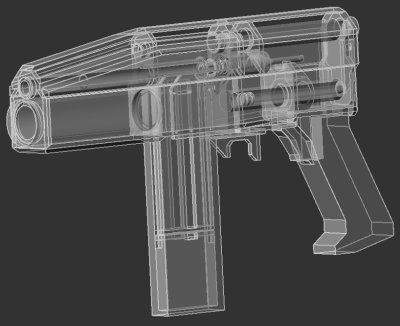

I used this to shop for the appropriate parts and then replicate those parts in CAD. It took quite alot of time to decide upon parts and then work out how best to arrainge them in the best functional setup that also allowed for a workable weight balance. After several days of CAD work I now have this mostly-complete model.

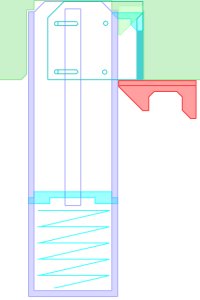

29 inches long and presumably around 20lb. Weight balance is centered slightly behind the grip. 20-round clip (weakly spring-loaded). No shells. The "trigger" right behind the clip is a clip eject. The clip keeps the darts inside when not loaded in the gun.

The main tank is in front and may need to be enlarged to allow for more capacity. The pump is in the center and the battery is in the very rear.

The ideal pump I've found is a 12v diaphragm pump meant for pumping water (but also works with air) in recreational vehicles. It doesn't draw too much current, which was an issue with piston-pumps which drew a minimum of 10 amps.

I will eventually get around to making this but I'm not exactly sure when.

The gun is rather large. A manual pump and a smaller battery for just the solenoid could be used to make this a much smaller and lighter gun if I decide that I want something more portable. Or better yet, maybe I can find a smaller more efficient pump. I haven't really decided yet.

Edited by CaptainSlug, 09 May 2006 - 11:54 AM.