Edited by nerfer34, 15 October 2006 - 09:17 AM.

#26

Posted 16 May 2006 - 07:13 PM

#27

Posted 16 May 2006 - 07:28 PM

He's already posted pictures of his in-progress CSHG, which is rather impressive. Read up before you start bashing him.

Here's the link.

Seriously people. Just because you can't do it doesn't mean someone else can't. I mean hell, after looking at what he's done via the link in his sig, I don't doubt he can do it, and the pictures he has presented of his work so far proves it.

Just because something seems difficult doesn't mean you can't do it. When I first saw Bolt's FAR I knew that I wanted to make my own version, but never thought I could do it. While it took me a long time to design everything and then put it all together (mainly due to the multiple versions I had to make before one worked), I proved to myself that it could be done.

I'm no older, or more experianced, than most of you guys at making homemades when I first started in the homemade arena. If I'm capable of making functional homemades, you all can to. It's just a matter of how much patience you have.

~ompa

#28

Posted 16 May 2006 - 10:49 PM

Yeah, It's definitely not a powerful pump. But at the price I paid I don't really care. I'll see if it can pressurize the small tank to the level I want in a reasonable amount of time. If it can't I'll just get a larger diaphragm pump later.Hold your horses there, FH. The compressor is small and battery-powered, but the output is HORRIBLE. It says that it can fill a standard tire to 35 psi in around 8 MINUTES. That's a LONG time. I realize that most projects wouldn't use a tank quite so big, but it would still be excruciatingly slow to fill most anything.

Nope. But there are plenty of things I had previously never built but understood well enough to have designed, and then later build. Like computers, computer cases/parts, furniture, dry ice containers, 3D models, and battlebots. When it comes to Nerf homemades, like many things, I'm still green. But I do have adequete experience in all of the related skills required to make them and I look forward to proof-testing my design.I REALLY REALLY don't want to sound like a jerk but captain slug have you actually ever built a homeade?

And everyone is welcome to doubt me if they want to. I'll just keep making progress on CSHG and the other projects I'm behind on.

Edited by CaptainSlug, 16 May 2006 - 11:00 PM.

#29

Posted 17 May 2006 - 06:04 AM

Anyway good work

You said you were looking at that little pump, and i know people have already comented but i to dont think its the best pump to use for such a job. I dont actually nerf i just like the concept, but i can imagine you need something thats quick and powerful. Although 30 psi will hurt i dont think that you will be able to fill a tank up quick enough. Even if you were to fill a Massive tank then regulate it, it would still chew through time. I quess the only idea that pops into mind is to have a small tank with the pump ALWAYS on. However it will prove abit anoyin if your trying to stalk, as your oppent might just here the humming of the motor.

P.s. Whats happening with the gattling? Looking forward to that project looks kick ass. Keep up the good work and the "Fancy Pictures".

#30

Posted 17 May 2006 - 11:31 AM

Hold your horses there, FH. The compressor is small and battery-powered, but the output is HORRIBLE. It says that it can fill a standard tire to 35 psi in around 8 MINUTES.

I quess the only idea that pops into mind is to have a small tank with the pump ALWAYS on. However it will prove abit anoyin if your trying to stalk, as your oppent might just here the humming of the motor.

These posts gave me an idea. I read the specs of the pump, and while it's output is pretty slow for something as large as a car tire, it's pressure handling capability is great, 150 PSI. So, moving off of what SKIZ said, you could possibly create a system that runs off of high pressure, using a smaller tank. Precharge the tank before hand. Regulate the output using a firing chamber. Connect a pressure gauge to the main pressure tank; when the pressure dips below a certain level, the pump could kick on. It'd work better than having it always on...it'd save batteries, and it'd keep you from having to have an overpressure release valve on your air tank, and having the first Nerf gun that sounds like a city bus. PSSSSHHHttt...

The gun would still have pressure when the pump kicked on; the pump would just work to maintain pressure levels, rather than establish them from empty. No, not a stealth gun, but semi-auto sounds more rushing to me, anyway.

#31

Posted 17 May 2006 - 06:44 PM

NOTE: i take back what i said about this pump after actually reading the specs full way through i relised that it might be ok after all. )I didnt see the 150psi part) 150psi would be great regulatored, a full tank should prove many shots. However make sure you can adjust when the pump kicks in, and make a manul override as you may whant to it kick in at about 25% capacity. I quess the best thing to do is just adjust it so that you will NEVER run out of air but at the same time, not ALWAYS haveing the pump going.

Edited by SKIZ, 17 May 2006 - 06:53 PM.

#32

Posted 17 May 2006 - 07:17 PM

Such is the plan in conjunction with my mechanical tank pressure regulator. And the battery life on the AirMan pump is weak, but that's fine because I won't be using the stock battery. I picked it because it's current draw is so low that it will get really good battery life with the same battery I'll be using for CSHG. But should still provide enough output to be usable.These posts gave me an idea...

And a standard store-bought regulator will go inbetween the main tank and the charge tank so that the charge tank will only be firing with 10 or 15 psi.

To get a minimum and maximum PSI for the main tank (so that it doesn't charge the main tank after every one or two shots) I may need to make a small circuit board or use a very high output capacitor.

Edited by CaptainSlug, 17 May 2006 - 07:24 PM.

#33

Posted 25 May 2006 - 01:25 PM

Is it possible to make this a bullpup design? (Clips in the rear, and the grip and trigger in the front) With a bullpup design, the barrel will be longer with the same gun size as now. I assume it's possible as it is using pressured air to fire.

Edited by Jikman, 25 May 2006 - 01:26 PM.

-Friedrich Nietzsche

#34

Posted 25 May 2006 - 01:30 PM

Of course. You would just need a long linkage arm from the trigger to the valve.Hey CaptainSlug,

Is it possible to make this a bullpup design? (Clips in the rear, and the grip and trigger in the front) With a bullpup design, the barrel will be longer with the same gun size as now. I assume it's possible as it is using pressured air to fire.

#35

Posted 25 May 2006 - 05:18 PM

Guitar Heroes-Jimmy Paige, Eric Clapton, Jimi Hendrix, Kurt Cobain

Newly Found(thanks General)-Yngwie Malmstein, this guy is an accoustic expert.

#36

Posted 25 May 2006 - 11:23 PM

That would be an interesting chart to have.

#37

Posted 26 May 2006 - 05:11 AM

If you've got high pressure, then you need low volume.

If you've got low pressure, then you need high volume.

For a nerf dart, the high pressure low volume tends to work well, where as with a cannon, low pressure high volume works well.

As far as actual psi... I have no idea. In writing this, I realized I probabaly wasn't any help. Sorry for that?

#38

Posted 27 May 2006 - 09:16 PM

I asked GeneralPrimevil since he's built several large volume air-compressor-fed pneumatic cannons and his experience points to 10-15 psi being the effect pressure level for firing darts 80 to 100 feet.Ummm... Does anyone know how much pressure is required to fire a nerf dart?

#39

Posted 06 October 2006 - 01:52 PM

here is the CAD file and Mcmaster part list that the CAD file is designed around.

http://www.captainsl...om/nerf/abp.zip

The file format is from Alibre Xpress, which is a free trial version of the full software http://www.alibre.com/xpress/

Tools required

+ Drillpress

+ Scrollsaw

+ Tablesaw (Or a comparable tool for doing precise squarely cut pieces from sheet plastic)

+ Weld-on #3 Plastic Solvent Adhesive

The gun is designed to be made from nested lengths of standard sizes of widely available plastic tubing and shouldn't require any lathe work. Lots of precise cutting and drilling work however is required, and to make the process easier you can use my method of creating printable cutting template sheets from the CAD file.

http://www.ocforums....322&postcount=3

Edited by CaptainSlug, 06 October 2006 - 01:55 PM.

#40

Posted 24 April 2007 - 01:36 PM

Here are the new project goals.

1. True Semi-Automatic

one trigger pull fires one dart, releasing the trigger resets the cycle.

2. Built around the longshot magazines

Not having to build a magazine from scratch would save me alot of time and hassle.

3. As many ready-made parts as possible to reduce machining time

The original valve design works identically to commercially available directional control valves. Buying one of those will save me a ton of time.

4. Redesign breech actuator

The current position and configuration involves too much friction, too many individual parts, and not enough surface area for the working pressure to operate against. This part will be moved to ahead of and above the breech.

Doing all of the above will make the resulting design EXTREMELY SIMPLE by comparison to the original concept. Provided I can find the funds to get this made getting it working should be too difficult. I think it should be fairly easy for someone other than me to make and will still have the option of being able to be hooked up to a traditional bike pump.

Will post more once I have the CAD work done.

#41

Posted 24 April 2007 - 07:00 PM

Best of luck,

Butt

This contest may have some flaws, as people can simply be a deuschbag over the internet. By Lying.

A war-like setting/invitational would be better...

#42

Posted 25 April 2007 - 05:38 PM

I think I can help you with that. Awhile back I tried to design a true semi-auto gun that ran off low pressure air. When looking for designs to base it off of I found these paintball diagrams. (Not my pics)Okay, this design never went anywhere due to lack of time but I've been researching pneumatic control parts and I'm working on an HPA tank and regulator setup so I'm reincarnating this project.

3. As many ready-made parts as possible to reduce machining time

The original valve design works identically to commercially available directional control valves. Buying one of those will save me a ton of time.

4. Redesign breech actuator

The current position and configuration involves too much friction, too many individual parts, and not enough surface area for the working pressure to operate against. This part will be moved to ahead of and above the breech.

I decided with all the millions of dollars they pour into paintball R&D the current designs must be the most efficent and quickest out there.

As you can see from the pics, the Angel (the fastest firing marker EVER) uses a limited number of parts and is therefore more efficient. And if you intend to use solenoid valves to control firing, I suggest using paintball solenoids. They're smaller, need less energy, and can handle more pressure than standard valves.

#43

Posted 25 April 2007 - 06:30 PM

I will not be using solenoids in the new design. And paintball systems aren't suitable for use with Nerf because they're designed for higher pressures.I decided with all the millions of dollars they pour into paintball R&D the current designs must be the most efficent and quickest out there. sure than standard valves.

I already have the entire gun designed in my head and all I will have to make is the barrel/breech and an air cylinder, then a body with a magwell.

Edited by CaptainSlug, 25 April 2007 - 06:32 PM.

#44

Posted 25 April 2007 - 08:08 PM

#45

Posted 25 April 2007 - 10:25 PM

Paintball markers typically operate at pressure levels around 850 psi, and some times as low as 70 psi. I need to drop down to around 20 psi in order to avoid turning the darts into confetti.

I'm about half of the way through the CAD work but will wait to post images until it's done.

Edited by CaptainSlug, 25 April 2007 - 10:25 PM.

#46

Posted 26 April 2007 - 01:51 AM

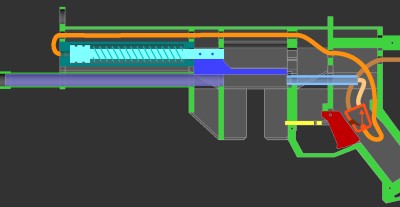

Mechanism is the same but the parts are simplified a good deal. Diagram here shows after the trigger has been held down for a second.

The trigger trips a directional control valve which alternates the plunger chamber between the tank supply and the exhaust port into the barrel.

When the plunger chamber is pressurized (whenever the trigger is released) the breech will be actuated closed by the supply pressure.

When the trigger is pressed the plunger chamber will depressurize through the the barrel, thus firing the dart. Once the plunger chamber gets below 5psi the spring will no longer be compressed and the breech will open.

The resulting cycle is semi-automatic since the cycle is non-repeating and relies on each trigger pull or release to change states.

The gun is designed around the measurements of the stock longshot magazines. And in order to remove or replace a magazine the trigger has to be held down, and the magazine catch has to be pulled back.

Edited by CaptainSlug, 27 May 2007 - 11:06 AM.

#47

Posted 26 April 2007 - 04:59 PM

Anyways, nice designs.

Without the stock and the breech actuator thing on top it looks like a Mauser. But with the LS mags, the magwell will be much wider.

With homemade mags you could've made this look even more like an MP5k, which happens to be, in my opinion, the best looking gun (except for the fat front handle).

Next one who wants to be Michael Jackson, and save the world, gets a trip to Neverland.

Buy Boltsniper's guns!

Borrowed by FoamReaper of Boltsniper Forums.

#48

Posted 26 April 2007 - 05:18 PM

The intention is to use 12-round longshot magazines. Making magazines from scratch would be too tedious.

Edited by CaptainSlug, 26 April 2007 - 05:22 PM.

#49

Posted 26 April 2007 - 09:20 PM

#50

Posted 26 April 2007 - 10:14 PM

There's really no need to complicate an already simple design that I'm sure will work. This design really only has ONE MOVING PART that I can make easily out of standard sizes of plastic rod and tube so making it won't take all that much time.

I've already sourced and purchased the parts I need to down regulate the tank pressure to 20 psi, and the mechanism I've designed will operate effectively at that pressure level since the cylinder has a such a large working surface area. Most air cylinders and valve systems are not designed to operate effectively at a such a low pressure. If you were to try and actuate them at a forth of their rated pressure you would get significantly reduced speed and a very very low pushing force.

I just have to get around to purchasing the materials so I can get started. I'm hoping to start this in a week or two when there's a break between semesters.

Edited by CaptainSlug, 26 April 2007 - 10:26 PM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users