#51

Posted 06 April 2006 - 08:55 PM

Do you want an actual windshield-wiper switch? I think I might have one lying around somewhere...just pay for shipping and I'll be fine. I just need to find one for those amperages...that'll take all of a few minutes, hopefully.

10-15lbs? You think that is heavy? My SOBR weighs in at 4.9lbs and I still have to add a few more. Just make it so you have to hold the sucker like a movie-minigun, with the pistol grip in the rear and a forward handle. That makes it seem re-damn-diculously light. Seriously, then it could weigh up to 40lbs and you would then feel the difference. Better yet, Venom-ize it so that it is fired like a normal rifle. Seriously though, ten fifteen pounds is light. I mean, re-cock-ulously light, compared to some stuff I've had to haul a-field before...I like heavy things, however; hence, I am making the SOBR as heavy as I can get it. My goal is to make it at least 12lbs by sundown to-morra.

#52

Posted 06 April 2006 - 09:04 PM

The trigger will probably be a momentary interlock switch.

I wanted to use a variable speed trigger switch, but those are absurdly expensive ($20-$40 each!)

We'll see what the final weight ends up being. The battery alone is 6lb and the motor is 6lb as well. I haven't bothered to weigh the PVC yet but the 4-inch PVC pipe is a little on the chunky side so the only other comfortable configuration would be having the grip on the top.

The grip and battery compartment will be added last so the placement of those parts will be decided more definitively once I get the main mechanisms of the gun working.

I do have a joystick grip I could scalp if I decide upon a more traditional grip setup.

Edited by CaptainSlug, 06 April 2006 - 11:53 PM.

#53

Posted 07 April 2006 - 08:21 PM

Pics

The harness

The gun

Edited by murakumo32, 07 April 2006 - 08:28 PM.

-or-

100% Nerf, for 100% pwnage.

Nerf is a neutral weapons dealer. Anyone coughing up the dough can get armed.

and they're made of Foam... which makes them very Nerfy...

#54

Posted 07 April 2006 - 08:37 PM

Okay, I'm gonna have to try my hand at making an automatic eventually. Lemme look at my building schedule for the next three months *looks through roster**finds that all projects are either in disrepair or unable to be finished* I have room...Ha, it looks as if Flaming Hilt might get his wish of a turreted gun in a van for MidMI...muahahaha...

Hopefully you get that thing done within the next month, 'cause I seriously need to see a finished product.

#55

Posted 07 April 2006 - 08:42 PM

Edited by Forsaken_angel24, 07 April 2006 - 08:42 PM.

I don't feel the way I used to do.

I know its bad,

After what we had,

But I’m just not the angel you knew.

#56

Posted 07 April 2006 - 09:58 PM

Well, I'm using the same parts that Carbon used to make the Snap 1 Mk.2, except that I'm using an AR15 action spring (2 inches longer than the spring he used) so the plunger travel is 6 inches instead of 5. 50ft should be a piece of cake. Anything beyond that will be icing.That would be the definition of kick-ass, no matter how it turned out as long as it fired at least 50ft. I mean, major kick-ass.

And I don't think it will be heavy enough to warrant a balancing arm. A shoulder or neck strap might be nice just for carrying puposes though. UPS dropped off some goodies this evening so I'm going to start cutting stuff tomorrow.

Edited by CaptainSlug, 07 April 2006 - 09:59 PM.

#57

Posted 07 April 2006 - 10:11 PM

Hmm...two barrels, two systems...Mine'll be a bit different, especially since I'm not going to be governed by batteries and whatnot that you were. I could still use something to that effect, but I'll just wait until my AutoCAD LX or LS or whatever its called arrives...

Well, hurry it up lad! But always remember, measure twice, cut once. Or, be like me: never measure, use a mallet 'til it fits.

#58

Posted 07 April 2006 - 10:51 PM

Reminds me of that greek king I beleive that was the only one strong enough to string and fire is bow.

Odysseus?

CS, I'd still say to stick with the shoulder-fired configuration, because you don't see that a whole lot with miniguns, and it would be really awesome.

#59

Posted 08 April 2006 - 01:37 PM

Of course, you could just go for shock value and make a second one, using both with single pistol grips.

#60

Posted 08 April 2006 - 08:04 PM

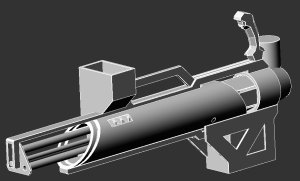

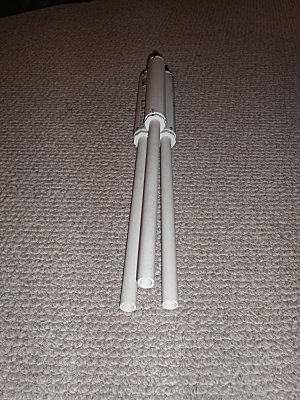

(6) 1" PVC bushings

(3) 10.5" lengths of 1-1/4" PVC

(3) 11.5" lengths of 1/2" OD PVC Type I round rod

(3) 15" lengths of 1/2" PVC

(3) AR15 action springs

First I marked the bushing every 90 degrees using a sharpie. I used those marks to duplicate them on the ends of the 1-1/4" PVC pipe.

I measured the preferred distance for the screws on the bushings taking into account the thickness of the sheets that the bushings will have to attach through by making a temprary spacing guide from a scrap of polycarbonate.

I used this measurement to mark where I needed to drill the holes on the 1-1/4" PVC pipes.

Using the vice with temporary leveling marks I drilled 7/64" holes in both the bushings and 1-1/4" pipe. I then widened the holes in the 1-1/4" pipe later with a 5/32" bit.

I then tapped the bushing for #6-32 screws. The bushings that will attach to the barrels will need to be wrapped in silicone tape, and the bushings for the rear of the tanks will be shortened by 1/2".

The plungers took more time to perfect than it took to do all of the previous steps combined. Here is what I settled upon in the following order.

1. #6-32 1-1/4" machine screw (I should have used ones with a flat undercut head but the local store didn't have any so I was stuck with pan head screws)

2. #6 3/8" washer

3. 1/4" washer

4. #6-32 hex nut (keeps the fender washer centered)

5. 1.5" fender washer

6. 3/4" rubber bumper foot

7. 1" rubber bumper foot

8. PVC Type I 1/2" OD round rod

The 3/4" rubber bumper allows the fender washer to deform enough to match the inner diameter of the 1-1/4" PVC pipe and the 1" rubber bumper foot holds the spring. The 1" rubber bumper foot could be replaced with a 1" OD washer but I didn't have any that had a small enough center hole to keep it centered on the #6 screw. I also couldn't find fender washers with a small enough inner diameter, which is why the hex nut is used. A spacer could be used in it's placed if I had any small enough.

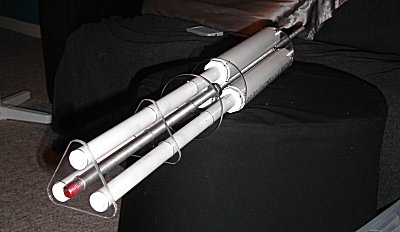

After applying teflon tape, using lots of spray silicone, and screw-mounting the bushings I now have 3 identical units. Next week after I get a considerable amount of homework out of the way I can start work on the milling for the breeches. Here's a preview of things to come...

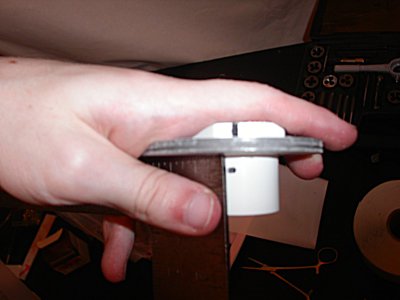

Also, to answer the grip problem I realized that I can leave the option for both. This is the joystick handle I plan to use.

I'm going to make an aluminum or polycarbonate frame for the inside. The thumb button on the top will be replaced by a removable cap. I'll make hardpoints on both locations on the frame of the gun so that I can change the grip location if desired.

The grip really only contains a momentary switch. Because of that I can easily put a receptacle next to each hard point that the grip will plug into. The speed selector switch will remain on the rear of the gun near the battery terminal.

Edited by CaptainSlug, 11 April 2006 - 05:46 PM.

#61

Posted 10 April 2006 - 08:26 PM

I've been meaning to try this for a while but haven't really had the time or need to do so. What I've done is I made a set of LARGE screenshot composite templates of the parts with the grid included and a marking square at a specific inch size. These images in inch dimensions are then set to the matching inch size on a page in Microsoft Word and then printed on full-sheet label paper. I can cut out each template, peel off the backing, and apply the templates to the protective film on the plastic sheets.

I don't have to do any re-measuring and I have accurate marks placed precisely where I need to drill and cut. This will save me alot of time and ensure that the placements are perfect.

Edited by CaptainSlug, 10 April 2006 - 08:26 PM.

#62

Posted 10 April 2006 - 08:44 PM

#63

Posted 10 April 2006 - 10:46 PM

#64

Posted 11 April 2006 - 12:32 AM

#65

Posted 11 April 2006 - 12:37 AM

1. May

or

2. I have $18k to spend

Edited by CaptainSlug, 11 April 2006 - 12:38 AM.

#66

Posted 11 April 2006 - 10:48 AM

#67

Posted 11 April 2006 - 05:28 PM

End of line.

Edited by CaptainSlug, 11 April 2006 - 05:28 PM.

#68

Posted 11 April 2006 - 05:35 PM

Mwahahahahaha!

End of line.

Noice. Very, very noice.

Keep the momentum going!

-Piney-

<!--quoteo(post=209846:date=Feb 5 2009, 06:27 PM:name=boom)--><div class='quotetop'>QUOTE(boom @ Feb 5 2009, 06:27 PM)

</div><div class='quotemain'><!--quotec-->

</div><div class='quotemain'><!--quotec-->It's to bad you live in hawaii I bet there are not many wars there.Wait what am I saying<b> you live in hawaii you lucky bastard.</b>

<!--QuoteEnd--></div><!--QuoteEEnd-->

#69

Posted 11 April 2006 - 06:10 PM

#71

Posted 11 April 2006 - 06:30 PM

Nerf is giving me a much needed break from a project that was becoming too stressful to work on at the moment.

Getting the breeches and feeding system working are the next big steps.

Edited by CaptainSlug, 11 April 2006 - 06:32 PM.

#72

Posted 11 April 2006 - 06:40 PM

#73

Posted 11 April 2006 - 06:52 PM

My freind: You cant hit from there

Me:Yes i can... BANG(from my singled AT2K)

My friend:OOOWWWWW My arm.

#74

Posted 11 April 2006 - 07:53 PM

Don't forget to eat your meat based vegetable substitute children.

#75

Posted 11 April 2006 - 08:19 PM

Tomorrow I have class all day so I won't get to the breech cutting until Thursday.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked